ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

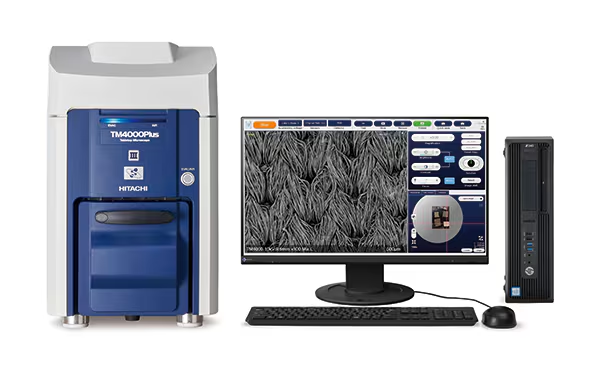

Hitachi High-Tech Zooms in on Quality in New SEMs

Hitachi High-Tech Corporation has launched TM4000PlusIII and TM4000III Tabletop Microscopes for the global market. Primarily, these tools are equipped with support features for automation and stable operation, critical to manufacturing environments.

Mainly, the TM Series shrinks the electron microscope to a size capable of being mounted on a tabletop. Thanks to their compact size and ease of installation, desktop microscopes are widely used not only for R&D. Also, they are used in quality control at manufacturing sites, science education at schools, and other purposes. Particularly, in manufacturing environments, there is a need to increase the efficiency of observation tasks and streamline operations so that even users with limited expertise can easily observe a large number of samples.

Specifically, the TM4000PlusIII is equipped with automation support features that enable users to create recipes for numerous conditions. Recipes can control functions such as stage position adjustment and magnification. Previously, they needed to be manually configured every time for each sample. In addition, they come equipped with maintenance features designed to facilitate consistent observation. One such function is a monitoring system that checks the condition of the tungsten filament* and graphically reports its condition. Tungsten filaments require regular replacement. Thus, this function allows users to track the filament lifetime and plan ahead with maintenance tasks to allow for smooth and consistent operation of the tool.

*Tungsten filaments: A single part used in the electron gun of an electron microscope. They are typically made by bending a thin wire made of tungsten (element symbol: W), which is a highly heat-resistant metal, into a hairpin-like shape and connecting it to an electrode. The tungsten filament emits an electron beam when heated.

Product Development Background

Hitachi High-Tech’s TM Series makes it possible to conduct high-precision observation and analysis, even when installation space is limited. Thus, it has come to be a critical tool during the development and quality control of new materials. Recently, the TM Series has contributed to conserving the environment and maintaining people’s health. To achieve this it is used to develop environmentally friendly materials and their manufacturing processes, as well as analyze harmful substances in the atmosphere. In manufacturing environments, the trend of decreasing feature size and stricter quality control has led to an increase in the number of SEM users. However, not all new users have specialized knowledge and operating skills.

Amidst this trend, Hitachi High-Tech has developed the TM4000PlusIII and TM4000III to have this sought-after optimization and simplification of observation tasks. Accordingly, it enables the acquisition of high-precision data without any variability, regardless of who is operating the microscope or their level of expertise.

Key Features

1. Making Tasks More Efficient

The automation support feature with the TM4000PlusIII allows for observation procedures. Among them are stage movement, magnification changes, and imaging, to be saved as recipes. They can then be executed to run automatically with a single click. This makes operations more efficient and standardizes techniques among users. This is beneficial for those looking to automate routine tasks and for users who are concerned about having to manually configure observation conditions.

Also, the TM4000PlusIII features a setting for high-current mode which enables faster operations due to the increased observation signal. For example, in particle analysis a large number of measurement points are required which can be very time-consuming to collect. The high-current function shortens measurement time for each location while reducing the overall time involved in such tasks.

2. Plan Ahead with the Filament Monitoring Function

Also, the microscopes come equipped with new support features to ensure safe use at all times. One example is the filament indicator feature. Specifically, it allows users to track the filament life on screen, preventing instances of observations being interrupted due to filament replacements occurring mid-observation.

3. Ideal for Educational Purposes

Particularly, the TM Series is equipped with low-vacuum and high-sensitivity backscattered electron detectors. Specifically, these detectors eliminate the need for complicated pretreatment processes. This makes it possible to conduct observations on a variety of samples with ease, enabling the TM Series to be utilized in educational settings.

Additionally, as digital skill development becomes a critical subject in educational settings, the TM4000PlusIII allows users to experience and learn important programming concepts such as “sequential execution,” “repetition,” and “conditional branching” via the automation support features.

Hitachi High-Tech will exhibit the TM4000PlusIII and TM4000III at JASIS 2024 at the Makuhari Messe International Exhibition Halls in Chiba, Japan, from September 4 through September 6, 2024.

Hitachi High-Tech aims to ship a target total of 6,000 TM Series units across the global market as quickly as possible to contribute to manufacturing worldwide. Further, the company will continue to refine its core analysis technologies. It will provide measurement and inspection solutions that support R&D and quality control operations in a wide range of fields. To this end, it aims to help improve people’s QoL (Quality of Life) and to resolve social issues related to the environment, resilience, and security and safety.

-22 August 2024-