ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Components Emerge for Next-Generation Vehicles

New product development of circuit components has been becoming active looking ahead to connected, autonomous, shared & services, and electric (CASE) trend. In particular, efforts have been focused on technological development with eyes set on the further progress of advanced driver-assistance systems (ADAS), autonomous driving technologies, and electrified vehicles (xEVs).

Recently, toward achieving autonomous driving vehicles, functional enhancement of the safety system, such as ADAS, has been advancing. The number of electronic control units (ECUs) incorporated in a vehicle has increased, and miniaturization also advances. Miniaturization is required for automotive-grade capacitors, resistors, and inductors as well.

To upgrade ADAS and autonomous driving technologies, it is necessary to improve communication quality and enhance safety. For this reason, the development of small and high-performance noise countermeasure components has been progressing meeting faster and higher frequency in-vehicle networks.

Millimeter wave (mmWave) radar units are required to meet high-density mounting to achieve smaller products. Circuit boards and hybrid boards, in which high-frequency circuit and general control circuit are fabricated on the same substate, have been manufactured using the modified semi-additive process (MSAP) method. Drastic downsizing of units has been pursued by constructing circuits using small components.

xEVs are driven by motors, while the controller, generator, inverter, rechargeable battery, DC/DC converter, and charger constitute important elements of the motor drive unit. For electronic components used in power units, reliability is strongly required to satisfy requirements unique to automobiles, such as resistance to high-temperature environment, vibrations, and shocks.

Aside from new aluminum electrolytic capacitors featuring the general electrolytic solution, the development of products such as conductive polymer aluminum solid electrolytic capacitors and conductive polymer hybrid aluminum electrolytic capacitors has recently been becoming active.

The technological development of highly reliable insulation transformers for insulated-gate bipolar transistors (IGBTs), high-power and high-performance current sensors, and high-efficiency reactors and choke coils has been progressing. Also, high-reliability high-power resistors and shunt resistors with low resistance are incorporated in xEVs.

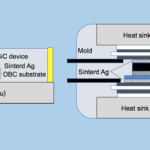

Amid all these components, efforts are also focused on the development of new products that match the technological trend of power devices with new wafer materials, such as silicon carbide (SiC) and gallium nitride (GaN) and feature high withstand voltage, high frequency, and high-efficiency switching.

Connection, Conversion Components

Support switches, touch panels, next-generation HMI

There has been active development of connectors that go in line with the CASE trend, and switches and touch panels that support next-generation human-machine interface (HMI).

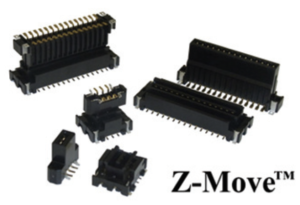

In order to cope with the increase in the number of devices incorporated in a vehicle accompanying higher functionality of vehicles, connectors are required to become smaller, meet high-speed transmission, high current and high voltage, and the development of high-quality, high-reliability connectors that meet these requirements has been progressing.

On-board cameras are important components for ADAS and autonomous driving. In addition to the increase in the number of cameras incorporated in a vehicle, these cameras have come to feature superior performance. The development of camera module connectors and camera ECU interface connectors for these high-speed digital sensing cameras has been advancing. Manufacturers focus efforts on the development of products that are compact and high performance and have excellent waterproof property, while achieving high-speed transmission performance, such as 3Gbps required for high-pixel automotive digital cameras.

As connectors for xEVs, high-current and high withstand voltage products used in the periphery of automotive inverters, motors and batteries have been developed actively. Products that support rated voltage of 850V have been developed.

For full-fledged popularity of EVs, improvement of the cruising distance per charge is crucial. For this reason, there are strong needs for weight reduction of components for EVs, and the development of compact and lightweight connectors for on-board ECUs advances.

The development of operation switches with excellent usability advances placing importance on safety. With switches for luxury cars, importance is placed also on quiet operation sound and smooth operation feel. From the viewpoints of operability and safety, the development of touch panels with feedback function advances. In addition, in order to respond to the trends of display monitors with larger screens and curved surfaces, accelerated development is also observed in these areas.

Among conversion components, thinner and lighter on-board speakers have been pursued against the backdrop of the transformation of in-car space into a living room in future complete autonomous driving vehicles.

On-Board Communication Modules, Sensors

V2X, 5G advances in on-board communication systems

Against the backdrop of ADAS and autonomous driving technology advancement, and the progress in evolution toward connected cars, electronic components manufacturers have been accelerating technological development of on-board communication modules and sensors. The development of 5G-compatible on-board communication modules has also been progressing.

With vehicle-to-everything (V2X) communication modules (IEEE802.11p standard) that perform vehicle-to-vehicle and infrastructure-to-vehicle communications, 760MHz modules have been put to practical use for the Japanese market. The development of 5.9MHz modules for the U.S. and European markets is also progressing. The IEEE802.11p standard features high speed, high reliability, and high security.

Recently, the development of automotive 5G NR modules equipped with cellular-vehicle to everything (C-V2X) function, which is indispensable for achieving full autonomous driving, has also been progressing.

Toward achieving fully autonomous driving vehicles, establishment of new on-board communication system that applies V2X system and 5G in an early stage is required. However, in order to achieve such system, it is necessary to upgrade communication function of conventional 4G Long Time Evolution (LTE) and achieve multifunctionality through the support of V2X to enable complex processing. This causes temperature rise of the module resulting from self-heating, and proper performance of the product cannot be exhibited.

As modules become larger as they become multifunctional, the optimization of module designs with consideration given to mounting on customers’ substrates is also required. Automotive 5G NR modules have solved these issues and sample offering of some products has begun.

Satellite positioning systems have also been developed. Modules and antennas supporting Global Navigation Satellite Systems (GNSS), which can receive signals from multiple satellite positioning systems, have been advancing.

Light detection and ranging (LiDAR) sensors are indispensable for Level 3 and higher levels of autonomous driving vehicles. An increasing number of companies has embarked on the development of solid-state LiDAR sensors that are compact, robust and superior in cost compared with existing mechanical LiDAR sensors.

LiDAR sensors measure distance by making laser light reflected at an object and measuring the time until the laser light comes back.