ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TSMC, Cadence to Surge Innovative 3DICs in AI

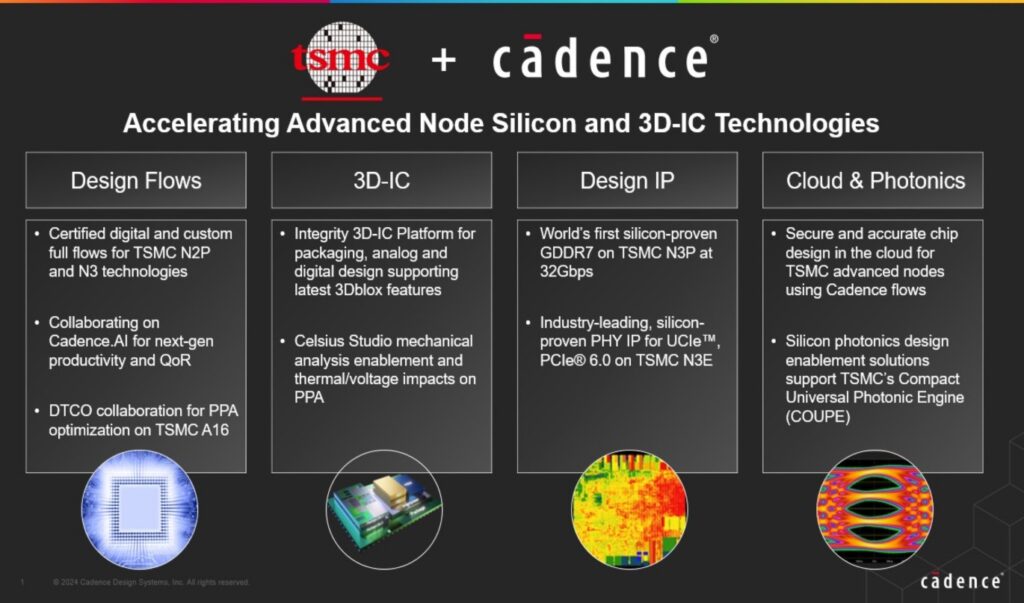

Cadence Design Systems, Inc. and TSMC are collaborating to enhance productivity and optimize product performance for AI-driven advanced-node designs and 3D-ICs.

Specifically, the rapid adoption of AI applications has created unprecedented demand for advanced silicon solutions. That is, capable of handling colossal datasets and computations.

To meet these escalating requirements, the industry is pushing the boundaries of advanced-node silicon and 3DIC technologies. TSMC and Cadence are at the forefront of this revolution. Thus, together empowering customers to accelerate time to market while increasing performance.

Three Main Domains

TSMC has certified Cadence’s industry-leading digital and custom design flows for implementation and signoff on TSMC’s latest N3 and N2P process technologies. As long-standing design technology co-optimization (DTCO) partners, TSMC and Cadence continue that tradition by collaborating to optimize power, performance and area (PPA) on A16. Moreover, adding EDA features to enable advanced features such as backside routing.

Cadence and TSMC are also collaborating on Cadence.AI to drive next-generation digital and analog design automation fueled by AI. Therefore, delivering industry-leading productivity and quality of results.

Cadence.AI is a chips-to-systems AI platform spanning all aspects of design and verification. The collaboration between TSMC and Cadence hinges on three main domains:

- First, the Cadence ® Cerebrus ™ Intelligent Chip Explorer applies AI to digital design for converging on the optimal PPA.

- Next, the Cadence Joint Enterprise Data and AI (JedAI) Platform uses generative AI for design debug and analytics, helping with PPA analysis.

- Lastly, Cadence’s Virtuoso ® Studio enables migrating legacy custom and analog designs to modern nodes and performs circuit optimization and high-sigma Monte Carlo analysis.

The Cadence Integrity ™ 3D-IC Platform is a leading system-level exploration solution and a single-vendor platform that unifies packaging, analog, and digital implementation. Therefore, making efficient 3D-IC design possible.

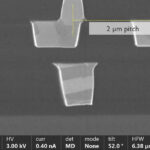

This opens new opportunities for innovation by supporting all the latest 3Dblox features and constructs. To enable the ultra-high-density interconnect in TSMC 3DFabric ™ technologies, TSMC and Cadence are collaborating on a next-generation high-capacity substrate router for die-to-die and die-to-substrate connections.

Critical for Success of 3DIC

Multiphysics analyses and optimization are critical dimensions of success for 3D-IC technologies. Furthermore, TSMC and Cadence are collaborating to enable warpage/stress analysis for TSMC 3DFabric. This is in addition to electrical/thermal analysis, and Cadence’s Celsius ™ Studio warpage/stress analysis simulation results have been validated. Thermal and voltage impacts on power/IR/STA are also enabled and verified inside the Cadence Integrity 3D-IC Platform for TSMC 3DFabric.

The AI factories’ insatiable appetite for data is increasing the requirements for interconnects and pushing power envelopes. Cadence has a broad portfolio of critical IP for efficiently moving data between chiplets and across data centers, including Universal Chiplet Interconnect Express ™ (UCIe ™ ) 1.0 , PCI Express ® (PCIe ® ) 6.0 and the world’s first silicon-proven GDDR7 on TSMC N3, running at 32Gbps, which provides the best price/performance for AI interfaces in both data centers and network edges. To address the growing communication challenges between these chips, Cadence silicon photonics design enablement solutions support TSMC’s Compact Universal Photonic Engine (COUPE).

In addition, TSMC and Cadence are jointly collaborating with the leaders in the automotive space. As the silicon content in today’s automotive designs continues to grow, IP development for current and future process nodes, such as TSMC N5A and later N3A, is even more critical.

TSMC and Cadence have also collaborated to showcase the accuracy and scalability offered by Cadence’s front-to-backend chip design flows on the Cloud for TSMC’s advanced process nodes. Thus, through this collaboration, mutual customers can shorten design schedules by adopting Cadence’s wide range of Cloud solutions .

26 September 2024