ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ZC Rubber Test-Runs Smart Factory Platform on 5G Network

Zhongce Rubber Group, or ZC Rubber of China announced an ambitious plan to use a 5G technology to create a replicable 5G smart factory platform for the tire industry.

On the way toward that goal, the Chinese tire maker is now constructing its own pilot factory to test run what’s called ZC Rubber 5G Smart Factory Project.

Aiming to keep up with the global tire industry’s three key trends – mass customization, small-batch production, and unpredictable disruption in the supply chain- the project is to rebuild the company all manufacturing facilities around 5G-based industrial IoT system.

Once completed, the Smart Factory platform will enable the tire business to transform from traditional B2M or business to manufacturer to C2M, customer-to-manufacturer business.

At the heart of the he smart factory platform are four key technology enabling systems; AR-based equipment maintenance , smart monitoring, indoor positioning, and intelligent early warning system.

Augmented realty, or AR is at the center of this visual system, allowing factory floor operators to interact with machines, offering visual guidance on equipment maintenance. The visual guidance will allow even some junior operators to quickly and accurately maintain machines ensuring a lower cost, higher efficiency, process reliability and standardization.

Coming built with 4K/8K HD video recording system and 5G- and machine vision technology- based real-time analytics, the smart monitoring system will enable operators to remotely communicate with experts at any time to get guidance on trouble-shooting.

The indoor positioning system can pinpoint where personnel are located real-time. When something goes wrong with the system, it can alert of safety warnings and emergency evacuation. This system will help navigate indoor to manage personnel, analyze workers’ behavior, leading to cost-saving, management efficiency, and accident avoidance.

The intelligent early warning system is to check the operating conditions of plant equipment, allowing the equipment lifespan to be optimized to its fullest. Combined with data research, it can also provide a comprehensive assessment of the operation conditions of plant machinery and equipment, which helps the factory discover the hidden dangers in time. This process, in the long run, will significantly improve working conditions and increase safety.

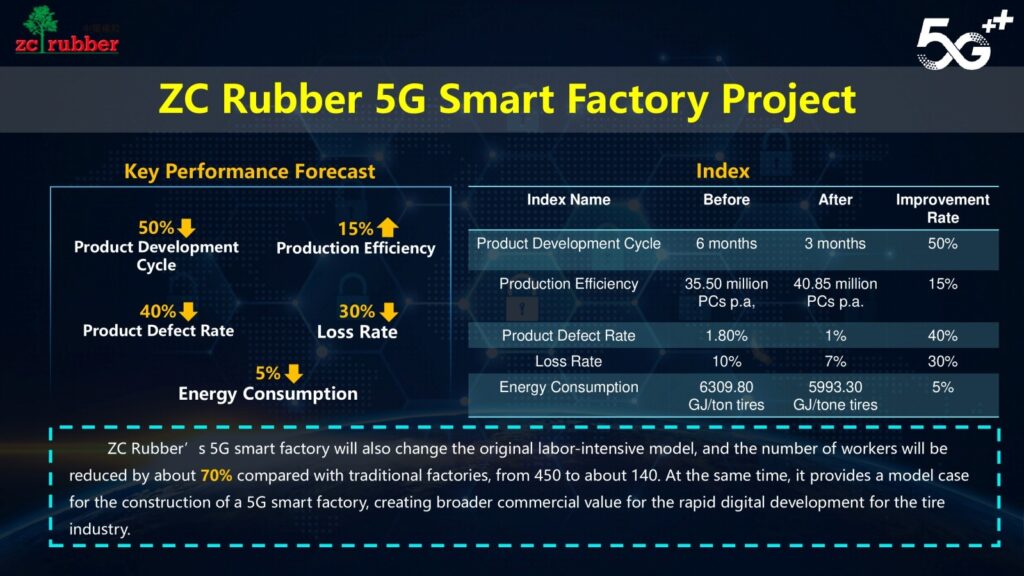

Compared with traditional factories, according to ZC Rubber, the 5G smart factory is expected to achieve a 50% reduction in the product development cycle, a 15% increase in production efficiency, a 40% reduction in product defect rate, a 30% reduction in loss rate, and a 5% reduction in energy consumption. In addition, the 5G smart factory will also change the original labor-intensive model, and the number of workers will be reduced by about 70% compared with traditional factories.

ZC Rubber, China’s No. 1 tire maker, has been aggressively pursued digital transformation of its factory operation to make its Smart Factory platform a commercial reality for the global tire manufacturing industry.