ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NEPCON Asia Brings Spotlight on Automation

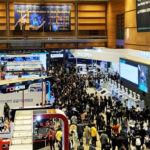

The success of NEPCON Asia 2021 reflects the renewed interests of manufacturers following revival of the Chinese economy.

NEPCON Asia 2021, organized by RX Greater China (RXGC), took place from Oct. 20 to 22 at Shenzhen World Exhibition & Convention Center. The event drew 1,200 companies from about 40 countries and regions. Japanese mounter manufacturers take center stage with their display of leading-edge manufacturing equipment and technologies.

Alongside NEPCON China, NEPCON Asia is China’s largest exhibition on manufacturing equipment focusing on surface-mount-technology (SMT)-related equipment and technologies. Last year, NEPCON China was cancelled because of the novel coronavirus (COVID-19) pandemic. This year, NEPCON China was held in April at Shanghai World Expo Exhibition & Convention Center.

Initially, NEPCON Asia was planned to open in August. However, the resurgence of COVID-19 in the South China district prompted the city government to close the venue. In response, RXGC decided to postpone the exhibition to October.

Revival of Chinese Economy

The Chinese economy has recovered from the COVID-19 pandemic and has continued to expand. According to the National Bureau of Statistics of China, the gross domestic product (GDP) from July to September increased 4.9 percent annually, compared to 7.9 percent from the previous quarter. Exports continued to increase with the reopening of economic activities in the United States and countries in Europe. However, production stagnated resulting from the global shortage of semiconductors and power supply restrictions in China. These factors contributed to the decrease of China’s GDP.

Demand for Automation

In the manufacturing industry, demands for automation and labor saving have been increasing owing to rising labor costs and manpower shortages. Infections from COVID-19 increased interests in labor-saving measures with less human risk, and full automation and unmanned production. These factors generally reflect the inflow of visitors at NEPCON Asia.

At the show, Japanese mounter manufacturers, FUJI Corporation, Yamaha Motor Co., Ltd., and JUKI Corporation showcased their machines through their local sales companies. Japan Unix Co., Ltd., Saki Corporation, Omron Corporation, and CKD Corporation took part through their distributors. ASM Assembly Systems set up its own booth. From Korea, mounter maker, Hanwha Techwin, as well as automated inspections (AOI) systems (AOI) manufacturers, KOH Young Technology Inc. and PARMI Co., Ltd. joined the exhibits. Taiwan’s Test Research Inc. (TRI), an AOI systems manufacturer, also took part. Chinese manufacturers exhibited soldering equipment, such as reflow soldering equipment; and mounting-related equipment, such as AOI systems; and industrial robots.

Manufacturers from Japan

FUJI highlighted the NXTR next-generation mounter, which is designed to fully automate the SMT line. As a new platform of FUJI Smart Factory with the Nexim integrated production system, it targets electronic components mounting line.

The company proposed the Digital Twin line, which makes use of Nexim’s simulation technology. It showcased SmartWing SW-BA board assembly robocall, sTowerⅡ automated components storage system, and automated maintenance unit.

Yamaha Motor Co., Ltd. set up a booth for itself and for WKK, its distributor, at two locations in the venue. The company showcased the YSM20R, YSM40R, and Σ-G5SⅡ premium modular mounters; YSi-V 12M TypeHS2 ultrahigh-speed high-precision high-end three-dimensional (3D) AOI system, and surface mount devices (SMD) storage system (components warehouse).

JUKI highlighted JUKI Smart Solution with SMT line at the core. The company featured RX-8, a new model of high-speed compact modular mounter. It achieves significant improvement in productivity through high-speed mounting of 100,000cph. It also exhibited the RX-7R mounter, JM-100 odd-form components inserter, RV-2-3DH AOI system, and ISM3600 electronic components warehouse. Through open innovation with other companies, JUKI proposed total solutions for the SMT line, including pre- and post-mounting processes.

Japan Unix exhibited its products at WKK’s booth. The exhibits highlighted the UNIX-DF303L laser soldering robot, which attracted a great interest of the Chinese automotive electronics industry. The company offers twin-beam and ring and other heteromorphic lasers, as well as single-spot laser, to best suit various applications. The company introduced in a video the newly released area laser, which is capable of simultaneous soldering of multiple points and supporting SMT.

Saki Corporation took part in the exhibition jointly with its Chinese distributor. The company exhibited its latest 3D-AOI system and other machines.

Just like in the previous years, Omron and CKD jointly took part in the event. They have been cultivating demand by promoting the coordination between Omron’s AOI system and CKD’s solder print inspection (SPI) system.