ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Apple, Applied Materials Flex More Muscle in U.S.-Made Chips

More companies are chipping in to boost the chip manufacturing ecosystem of the United States as part of the Trump government’s efforts to revitalize the country’s semiconductor industry.

Recently, Apple Inc. has announced a new US$100 billion fresh investment commitment, which increased the company’s commitment over the next four years to US$600 billion. In addition, Applied Materials, Inc. said it will work with Apple and American chipmaker Texas Instruments (TI) to further boost the chip manufacturing supply chain and pouring more investments.

End-to-End Silicon Supply Chain

Apple’s announcement forms part of the company’s commitment to the ambitious new American Manufacturing Program (AMP). Part of this commitment is shipping parts and components made in its U.S. factories, roughly two-thirds, to its customers outside the United States.

“Today, we’re proud to increase our investments across the United States to $600 billion over four years and launch our new American Manufacturing Program,” said Tim Cook, Apple’s CEO. “This includes new and expanded work with 10 companies across America. They produce components that are used in Apple products sold all over the world, and we’re grateful to the President for his support.”

To make this happen, Apple said it has partnered with thousands of suppliers across all 50 states supporting more than 450,000 supplier and partner jobs. In the next four years, Apple said it plans to directly hire 20,000 people in the United States, most of whom will focus on R&D, silicon engineering, software development, and AI and machine learning.

Among the big company names Apple is working with include Corning, Coherent, GlobalWafers America, Applied Materials, Texas Instruments, Samsung, GlobalFoundries, Amkor, and Broadcom.

With these partnerships, Apple is leading the creation of an end-to-end silicon supply chain in the United States. The company said U.S. silicon supply chain is on track to produce more than 19 billion chips for Apple products in 2025. That includes TSMC in Arizona, which is producing tens of millions of chips for Apple using one of the most advanced process technologies in America. Apple is this factory’s first and largest customer.

State-of-the-Art Facilities

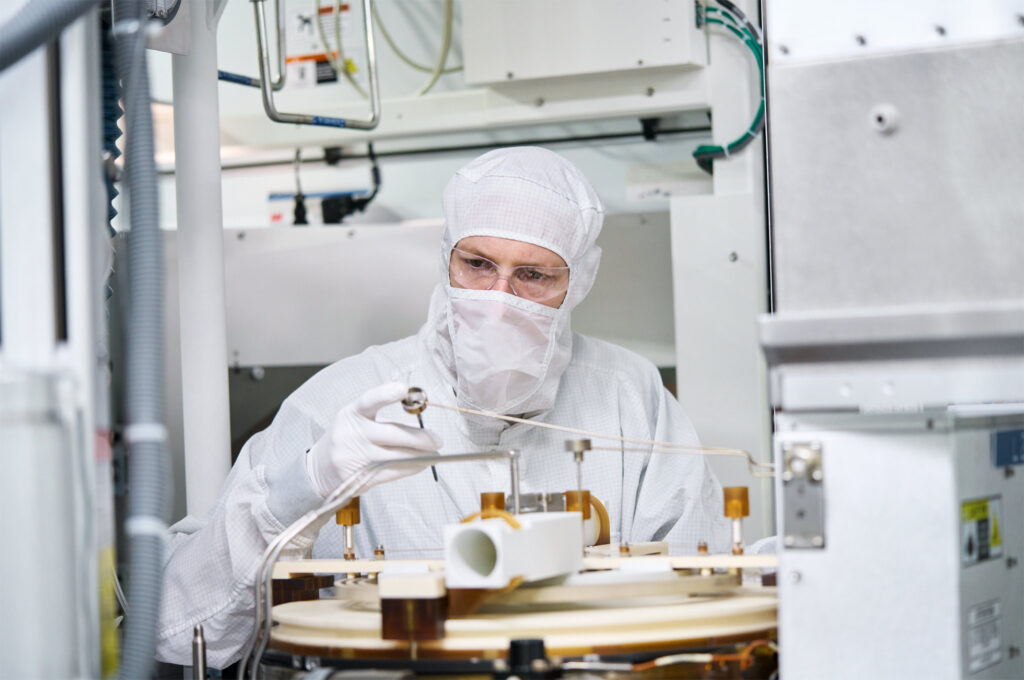

Meanwhile, Applied Materials also announced that it will support Apple’s partnership with TI by supplying American-made chipmaking equipment to TI’s factories. Austin in Texas is home to Applied’s largest manufacturing and logistics facility.

In addition, Applied announced plans to invest more than US$200 million in Arizona to establish a state-of-the-art facility for manufacturing critical components for semiconductor equipment. This investment builds on the more than US$400 million Applied has invested in its U.S. equipment manufacturing infrastructure over the past five years.

“For nearly 60 years, Applied Materials has been driving transformative innovation in chip manufacturing and ensuring the building blocks of technology are produced in the United States,” said Gary Dickerson, President and CEO of Applied Materials.

Applied Materials has the largest U.S.-based manufacturing footprint among semiconductor equipment providers, with major production facilities in Texas, Massachusetts, Montana, and a new site under development in Arizona.

The US$200 million planned investments in Arizona aims to create a new advanced manufacturing facility. Specifically, it will produce semiconductor equipment components and parts. The facility could support the creation of potentially 200 additional manufacturing, R&D and services jobs in the semiconductor field over a five-year period.

10 August 2025