ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

OKI’s Innovative System to Surge DX in SE Asia Plants

OKI Electric Industry Co., Ltd. has expanded its global manufacturing digital transformation (DX) solutions as it introduced on Nov. 25 its Projection Assembly System in Thailand and Indonesia. Specifically, this system will support assembly and quality inspection processes to drive DX of its manufacturing sites.

Accordingly, the system combines projector-based task guidance with image sensing technologies to help create manufacturing sites where anyone can perform tasks to uniform quality. The expansion of the system into Southeast Asia will enable quicker solution to a wide range of challenges encountered at manufacturing sites in different countries.

Reduces Error, Improves Productivity

Recently, manufacturing sites in Southeast Asia encounter challenges such as high labor turnover, workforce diversity, and inconsistent work quality. Particularly, assembly processes that rely heavily on manual labor require anyone who perform tasks to uniform quality, regardless of language or skill level.

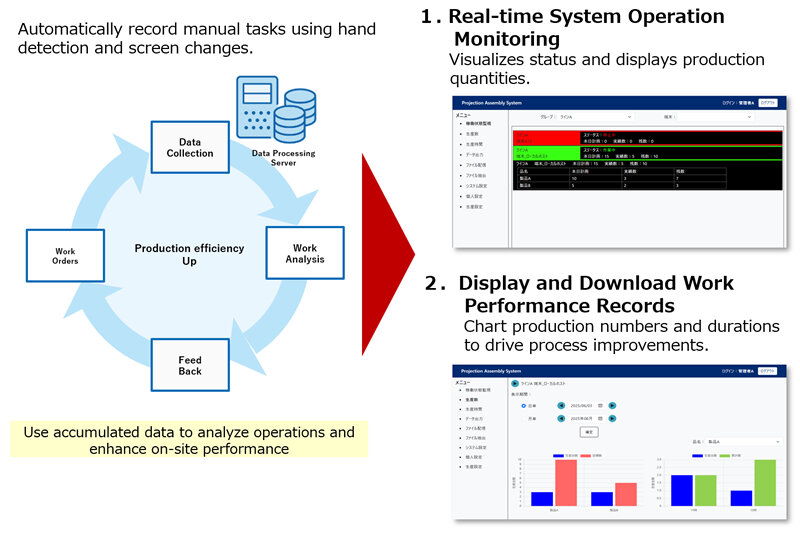

OKI has developed the Projection Assembly System to identify these issues and implement and verify improvements in OKI’s factory assembly processes. It uses general-purpose IT devices such as projectors and cameras to project assembly work procedures and checkpoints onto the workbench. Therefore, enabling uniform, high-quality operations regardless of individual workers’ experience and skill levels. The system prevents work errors, improves productivity, and supports skill transfer through on-site camera monitoring and AI-based feedback.

It features various new and enhanced functions, including multilingual support, streamlining of setup procedures, and real-time work status visualization to ensure uniform quality work regardless of worker’s language or experience.

Since its launch in 2018, the system has been introduced and operated at more than 100 manufacturing sites in Japan and at OKI’s overseas factories. OKI wants to expand support globally, starting in Thailand and Indonesia, to help customers facing similar challenges.

Expanding Sales Reach in Southeast Asia

Recently, OKI has sealed a partnership agreement with Mito Kogyo (Thailand) Co., Ltd. to expand the deployment of the Projection Assembly system in the Thai market. In the agreement signed on Oct. 28, 2025, OKI Systems (Thailand) Ltd., an OKI Group company responsible for printer sales, will serve as the main hub for this initiative.

Meanwhile, Mito Kogyo Thailand will provide one-stop services locally that will include sales, installation support, and after-sales service.

On July 14, 2025, OKI has also signed a similar agreement with PT. Netmarks Indonesia and expand the adoption of the Projection Assembly System within the Indonesian market.

OKI will draw on this partnership to strengthen its sales channels and customer base in the market. Netmarks Indonesia will provide one-stop services from local sales to introduction assistance and maintenance support.

25 November 2025