ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ASMPT SMT’s New SIPLACE V Sets Manufacturing Bar High

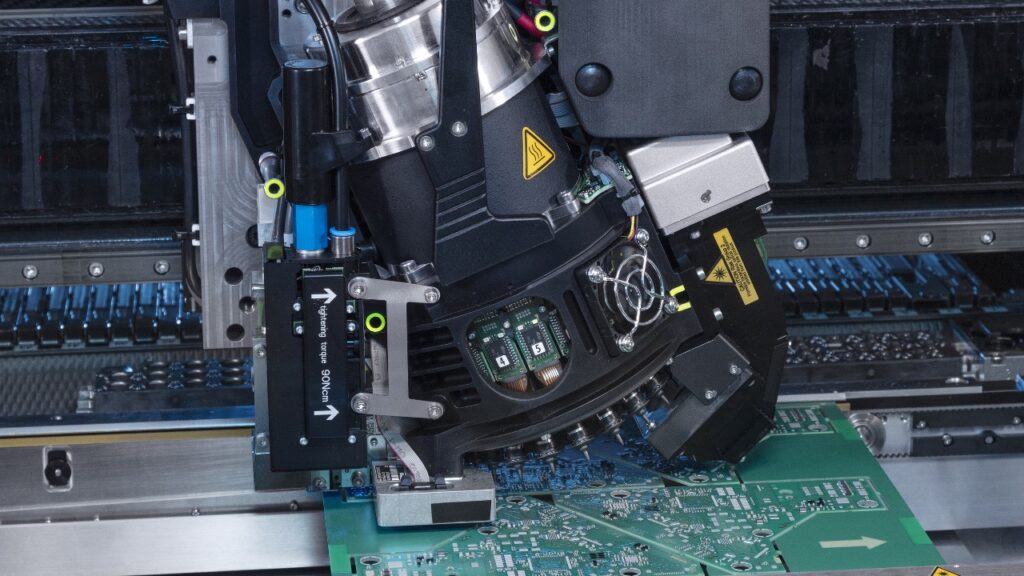

ASMPT SMT Solutions, the SMT solutions business segment of the Singapore-headquartered ASMPT Limited, has introduced SIPLACE V platform, its latest SMT placement system.

The new SIPLACE V platform features a significant performance boost of up to 30 percent and combining maximum speed with exceptional quality and flexibility. Therefore, ASMPT is setting new standards in electronics manufacturing with its compact footprint and full compatibility with existing ASMPT solutions.

Sets New Standards in Manufacturing

Automotive, consumer electronics, smartphones, IT and networking technology are critical sectors that require optimal tools and solutions all throughout the manufacturing process. For that reason, the SIPLACE V makes it possible for users to achieve performance improvements of up to 30 percent under realistic production conditions.

Initial tests showed the new placement platform from ASMPT SMT delivers performance increase not just in theoretical benchmarks but also in real production conditions.

”After some 25,000 assembled flat modules and 7.3 million components placed, we can confirm that the field test of the SIPLACE V platform in our high-mix, low-volume production was a complete success. The new placement machines from ASMPT are once again setting new standards in terms of performance, flexibility, quality and effective placement output,” says Martin Zistler, Vice President, Global Engineering at Zollner Elektronik AG.

Next-Generation Placement Heads

A central part of the SIPLACE V platform’s performance boost is the advancement in ASMPT’s placement head technology. By achieving a speed of up to 52,500 components per hour with a precision of 25 µm @ 3 σ, the SIPLACE CP20 collect-and-place head sets a new standard in high-speed applications.

The highly flexible collect and pick and place (CPP) head can switch between collect-and-place, pick-and-place and mixed modes based on software commands. This versatility makes it ideal for complex mixed-assembly applications in which it processes up to 28,000 components per hour with placement forces of up to 15 newtons.

Moreover, the SIPLACE TWIN VHF head is designed for particularly large and unusually shaped components. It processes components measuring up to 200×150×28mm and up to 100 newtons reliably and with maximum precision.

With a capacity to handle up to 6,000 components per hour, it opens up new possibilities for manufacturers in areas like the assembly of complex components such as BGAs, which play an increasingly important role in AI applications.

With the SIPLACE V platform, ASMPT SMT Solutions is setting new standards in terms of productivity and flexibility. It masters the full component spectrum – from ultra-miniature 016008M chips to large-format parts.

In addition, the platform also accommodates a broad spectrum of PCB formats, processing boards up to 400x280mm in dual conveyor while single conveyor boards can handle up to 700x530mm.

ASMPT SMT Solutions combines all these features and more in a footprint of only 1.1 × 2.4 meters, which sets a new floorspace productivity record in electronics manufacturing.

25 January 2026