ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yaskawa Electric Beefs up Welding Series with Laser Package

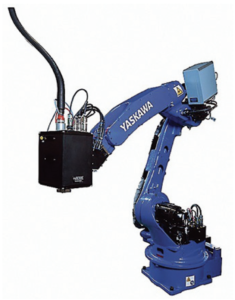

Yaskawa Electric Corporation has been producing the MOTOPAC Series, a package consisting of robot arms and welding equipment. Recently, it released the MOTOPAC-RL2D300-GP25JP laser welding package, containing the necessary and sufficient equipment required for laser welding as offered by the MOTOPAC Series.

The welding robots of the company include a wide range of products to meet customer needs for applications such as arc welding and spot welding. For applications for arc welding, the MOTOPAC Series has received high evaluations from the market. The package consists of the optimum combination of welding equipment including robot arms, welding torches, and welding power supplies.

Pursues Improved Welding Speed, Quality

In the welding industry, the development of laser welding technology that further improves welding speed and quality is in progress. However, the introduction of the laser welding equipment requires examination of many items, such as selection of the laser oscillator and laser irradiation head, combination with a robot arm, and control method. Thus, the company has commercialized a laser welding package consisting of total equipment required for laser welding. This enables smooth customer support in setting the conditions necessary for improving the welding speed and quality. In addition, it reduces the time and effort from equipment installation to actual operation as much as possible.

The compact and lightweight laser irradiation head developed by the company can be mounted on its medium-sized versatile robot MOTOMAN-GP25 (weight capacity 25kg), contributing to space saving of the equipment installation area. A part of the wiring and piping to the laser irradiation head can be stored in the robot arm, simplifying the handling and preventing interferences with the surroundings. Therefore, it is easy to use. Welding conditions such as wobbling welding function, welding speed, laser output, and angle of incidence can all be set with the programming pendant of the robot. The high-power (8kW) laser irradiation can achieve a welding speed 1.5 to 4 times that of the arc welding.