ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Toshiba’s AI Boosts Machine’s Predictive Maintenance

Toshiba Corporation’s artificial intelligence (AI) technology can state and describe the cause of the occurrence of abnormality on equipment used in plants. This capability is an improvement from the basic detection of abnormality of equipment that supports social infrastructure. The company targets to put it to practical use in FY2023 for predictive maintenance of infrastructure equipment.

Automatic Generation of Physical Model

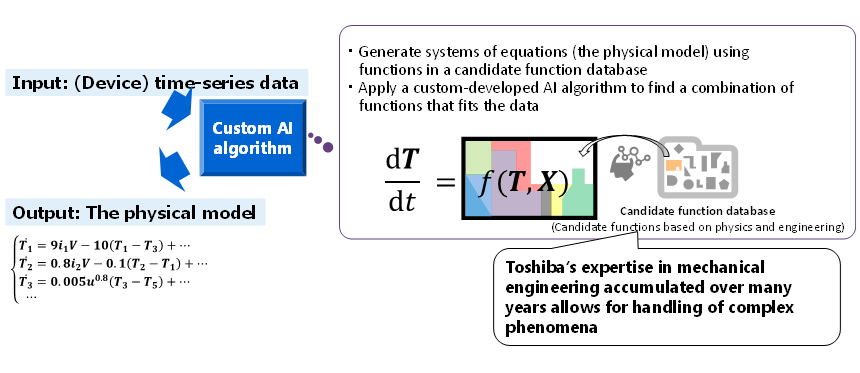

The AI automatically generates a physical model that describes the states and motion of a target device from measured time-series data. In addition, it shows not only abnormalities in equipment, but also the cause of the occurrence of abnormalities based on physical phenomena.

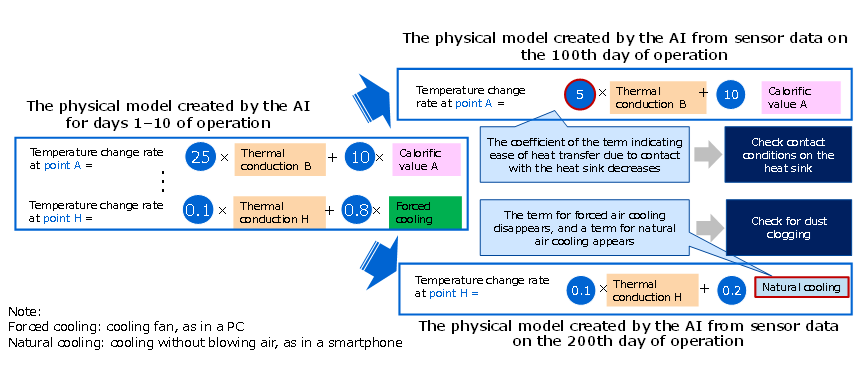

For example, the model made by the AI might indicate that an increase in equipment temperature is due to clogging dust. This makes improvement measures easier to formulate. The AI responds to complicated phenomena such as sudden changes in temperature and airflow. It can be applied to the maintenance of infrastructure equipment with complicated occurrence mechanisms. This feature will improve reliability of facilities and contribute to resilience in social infrastructure.

Determines Cause of Anomaly

Toshiba has designed an AI technology that can use a physical model with excellent interpretability to explain why anomalies occur. This technology automatically generates a physical model that describes the state and operations of a device from time-series data measured from that device.

In the automatically generated physical models, correlations between data items are represented as a network. Also, relations between items are represented as a combination of functions from physics and engineering. Candidate functions, which are stored in a database, are based on mechanical engineering knowledge that Toshiba has cultivated over many years, applying the handling of complex phenomena.

In conventional AI technology, it is difficult to efficiently combine huge numbers of functions without changing their physical meaning. Thus, Toshiba has developed a new AI technology that combines a new sparse estimation algorithm that can correctly consider the degree of physical influence of a function, a spatial search algorithm for efficiently selecting candidate functions, and a data expansion algorithm that enables highly accurate prediction. Toshiba succeeded in development of the AI for automatically making physical models with excellent interpretability.

The new technology eliminates the need for data such as the dimensions of a device and the physical properties of its parts. It is advantageous such that it generates physical models using only measurement data from sensors. This allows regular model updates during product or system operations. Analyzing changes in updated physical models allows detection of signs of product or system abnormalities and identification of their causes.

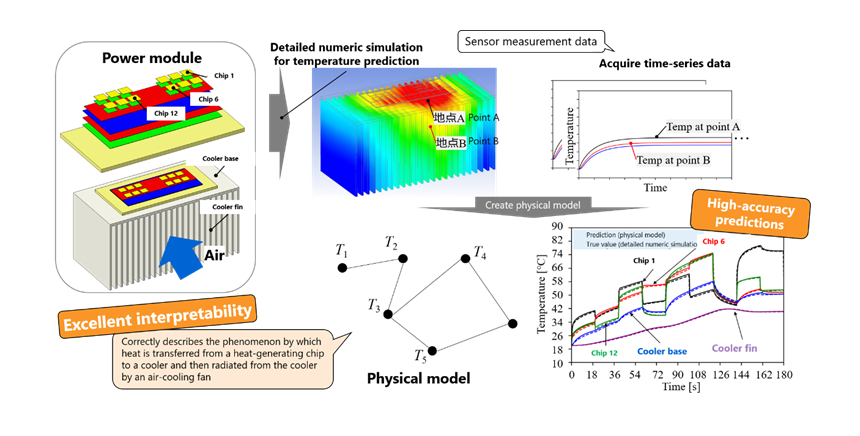

The AI was applied to temperature predictions, which is an important part of abnormality detection in power modules. Automatic generation of a physical model confirmed that a heat transfer method by which heat is transferred from a heat-generating chip to a cooler and radiated from the cooler by a cooling fan is correctly selected.

The generated physical model predicted temperatures with high accuracy (average error less than 1°C). It was possible to realize real-time predictive maintenance instead of performing a detailed numeric simulation, which would take thousands to tens of thousands of times more calculation time.

Growing Predictive Maintenance Market

Predictive maintenance is an increasingly important factor in the continued safe and secure use of products and systems. It is where equipment deterioration and defects are detected in advance for management in an optimal state. The market for predictive maintenance solutions is in the growth stage, reaching about US$6.9 billion in 2021, with projections for rapid growth at a compound annual growth rate of 31 percent to about US$28.2 billion worldwide in 2026.

Toshiba is working to reduce interruptions and downtime due to failures in equipment that support social infrastructure. It aims to establish highly accurate predictive maintenance technologies that minimize maintenance costs.

Anomaly detection and suggestions for solutions are indispensable aspects of predictive maintenance. However, many infrastructure devices generate abnormalities via complicated mechanisms. However, it is difficult to formulate improvement measures by using conventional anomaly detection technologies, which only show differences from the normal state. Taking appropriate measures and reducing maintenance costs will require technologies that can explain not only what is different from normal, but the causes of such differences.

Expand Features, Applications

The AI is highly practical for detecting abnormalities in products and systems, so application to various products and systems can be expected.

Toshiba will continue to expand the scope of this technology’s application to social infrastructure-related products and systems. It will continue to verify its effectiveness, aiming for practical application by 2023.