ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NVIDIA’s AGX Platform Expands Presence in Japan

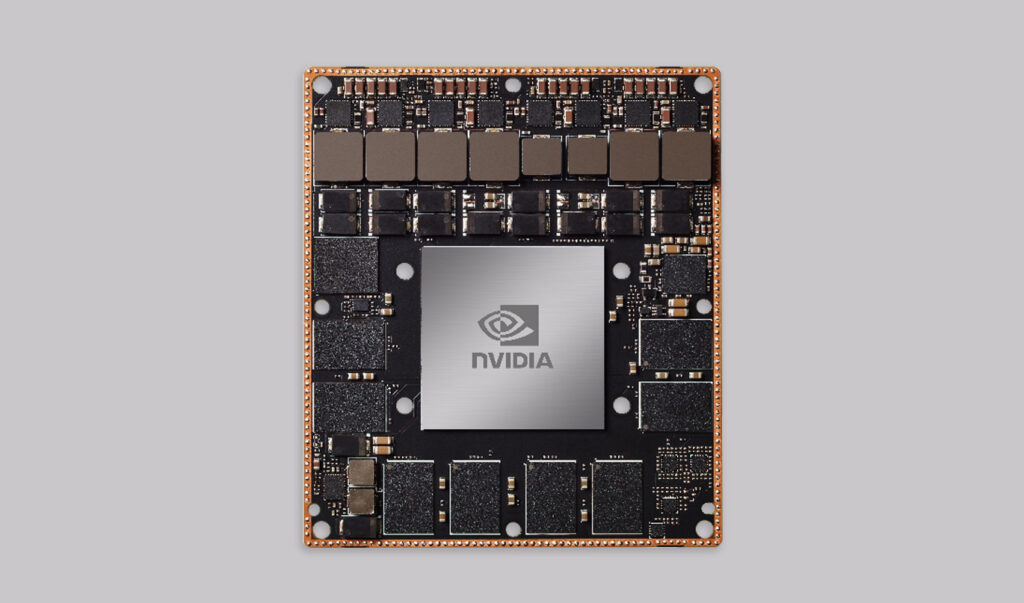

Ryoyo Electro Corporation has included in its portfolio the NVIDIA Jetson AGX Xavier Industrial module of NVIDIA Corporation, expanding potentials of this powerful module to Japan’s wide range of industries from medical, academe, and manufacturing.

The module has excellent durability in harsh environments and the latest safety features. It can easily create end-to-end AI robotics applications for manufacturing, delivery, retail, smart cities, and more.

NVIDIA Jetson AGX Xavier sets a new bar for compute density, energy efficiency, and AI inferencing capabilities on edge devices. It is regarded as the next evolution in next-generation intelligent machines with end-to-end autonomous capabilities.

Targets Factory Inspection, Robots

At factories, farms, construction and among other sites that handle oil and gas, real-time monitoring and predictive maintenance are required to prevent system failures and accidents. These work sites are always subject to drastic changes such as temperature fluctuations, shock due to impact and vibration, and in environments where manual work is not suitable. These scenarios call for AI and robotics applications.

In addition to extending the specifications of the resistance to shock and vibration, this module has expanded the operating range of temperature to -40 to 85˚, which enables construction of a very robust system.

It is equipped with the latest safety features controlled by the Safety Cluster Engine (SCE) and is suitable for use with safety certified industrial products. SCE is a general-purpose computing subsystem based on ARM Cortex R-R5 and acts as a functional safety management processor.

Ryoyo aims market the NVIDIA Jetson AGX Xavier Industrial module to work sites that heavily employ factory inspection equipment and robots as well as construction machinery for the purpose of predictive maintenance at construction sites.

The demand is expected also in oil and gas industry for surveillance, monitoring, predictive maintenance of work around hazardous pipelines and equipment; construction sites such as in safety device mounted on heavy machinery used outdoors; in farms for severe vibration and temperature environment and autonomous operation function of unmanned aerial vehicles, drones, tractors, etc. for spraying chemicals); and among many other applications.