ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

X-Ray Diffractometer Eyes Quality Control

Rigaku Corporation has released the MiniFlex XpC compact X-ray diffractometer (XRD). The company is the first in Japan to release an exclusive X-ray diffractometer for quality control. It is expected to contribute to improvement of analysis work efficiency, including the reduction of measurement time.

The X-ray diffractometer has been developed to meet the analysis requirements at the quality control site. This equipment promotes ease of use and supports measurement of multiple samples.

Features of X-ray Diffraction

Goniometer

The angle to irradiate X-ray is crucial in X-ray diffraction. In the past, the tube lamp (X-ray generating apparatus) was fixed and the position of sample was inclined to measure. If the sample spilled, the yield could deteriorate. This then requires improvements.

For the new product, the company has developed a goniometer, which adjusts the angle of the sample. The tube lamp and the detector move, allowing the sample to be measured while maintained in a horizontal state. When combined with software to correct angle in real time, the X-ray diffractometer achieves best angular accuracy despite its compact size.

High Output, Small Power Supply

Conventionally, the system tends to become larger in accordance with the operation range of the tube lamp. This time, the company has adopted a small tube lamp and a small power supply for X-ray source, thereby scaling down the entire system.

In order to obtain highly reliable data from samples, high output is required. For this reason, the company has increased output to 800W from 600W of the previous product, while reducing the size of power supply. Measurement of more samples has become possible.

Improved Detector

It is necessary to improve the detector in order to obtain highly reliable data. The MiniFlex XpC X-ray diffractometer has a detection area 1.5-fold that of previous product, thereby achieving twice the X-ray diffraction strength. Measurement time can also be reduced in half.

Loading Mechanism

It incorporates a loading mechanism to automatically transfer samples for the first time for a compact X-ray diffractometer. When an operator places a sample on the sample stand in front of the main body, the system automatically takes in the sample and starts measurement. This is performed without the operator touching the door of the system. As it has eliminated opening and closing of door, which previously took about 10 seconds, work efficiency has been improved. It can also be connected to an automation system by combining with a sample carrying system or belt conveyor.

Application in Variety of Fields

There are only few scenarios where the X-ray system can be used for quality control. Rigaku focuses on its potential for the global cement industry. Concrete has extremely high general versatility as a material, and there is infrastructure demand in emerging countries mainly in Asia. The composition of clinker, which is a raw material of cement, significantly affects the quality of cement. The company anticipates inquiries for the system in China and the Asia-Pacific region, including Southeast Asian countries.

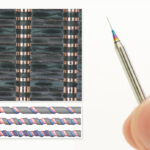

The crystal form (lattice constant) of electric components and materials, such as multilayer ceramic capacitors (MLCCs), determines dielectric constant. The X-ray system can be used to judge whether or not impurities are included in barium titanate, as an MLCC material.

It can also be used to evaluate anode materials of lithium ion rechargeable batteries. Thus, applications in various fields can be assumed.