ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Embedding Technique Lessens Environmental Load

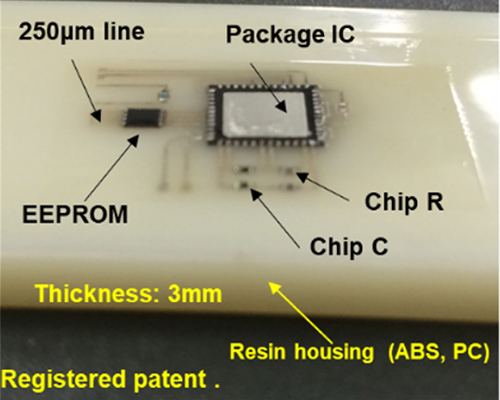

Mitsui Chemicals Inc. has developed the Eecomid technology that allows embedding electronic circuits in resin molded products. This technology enables manufacturing smaller and thinner electronic devices than before with low environmental load.

The term “Eecomid” means “Embed an Electronic Component into Molded Interconnect Devices,” or embedding electronic circuits in resin molded product.

The new technology can be applied to 3D printers, which are effective for prototyping and development, and also to injection molding, which is effective for mass production. Combining it with other technologies can shorten the development process. It can also lead to significant developments in various power systems.

Makes Smaller Devices with Low Environmental Load

The Eecomid technology incorporates electronic circuits into resin molded products. The electronic components and metal terminals are embedded in resin. Meanwhile, the electrodes exposed on the surface are connected by printed circuits made of conductive ink.

This technology does away with printed wiring board, which is an essential component of conventional electronic devices. It makes possible on-demand mass customization of products according to changes in hobbies and tastes. It allows the creation of products with new concept designs using unconventionally small, thin, and lightweight electronic devices, three-dimensional circuits, and flexible circuits.

With the new technology, no liquid arising from the use of chemicals and washing water associated with manufacturing processes such as plating and etching, is wasted. It does not require soldering, and energy consumption due to high temperature heat treatment is low. Eecomid can contribute to manufacturing processes compliant with Sustainable Development Goals, like utilization of water resources, reduction of chemicals, decarbonization, and reduction of simple work.

Application Areas

The new technology applies to forming electronic circuits on existing standard parts made of resin. It is adopted in forming electronic circuits for high-speed rotating parts (gears) and high-speed operating products (linear guides). Rigid flexible structure can be manufactured by integral molding. Eecomid also applies to thin electronic devices and in forming electronic circuits on every side of a cube. It can be used for bending the circuit at the edge using electrodes of electronic parts. Embedding an electronic circuit in a rubber-shaped molded product is another application of the technology.

Prototype Products

The development of the new technology is now in full swing. The company already displayed various prototypes at trade fairs last fall. Among the prototypes include a spur gear and a cap of PET bottle, in which electronic circuits such as sensors are embedded inside without changing the shape of existing products. Prototypes of a chip resistor embedded in a transparent circuit and LED blinking parts were also developed.

The company will further pursue environmental-friendly process, including the use of biodegradable resins. Products from this technology have been verified to have excellent resistance to vibration and shock and to environmental conditions.