ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ABB Releases New OmniCore Robot Controllers

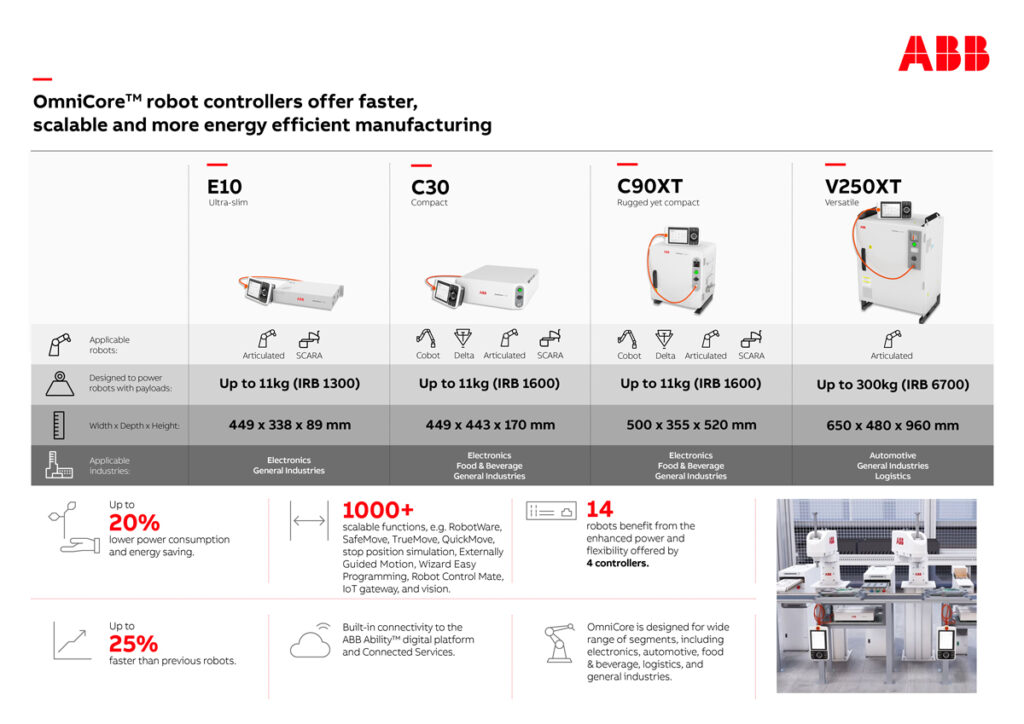

ABB has added two new members to its OmniCore controller family to meet the demand for faster, more efficient production.

The new E10 and V250XT controllers offer best-in-class motion control and 20 percent energy savings for a range of robots across ABB’s portfolio. They provide future proofing through built-in digital connectivity and 1000+ additional functions to meet changing requirements.

These two new controllers extend the possibilities for enhanced robot control in a variety of industries. These industries range from electronics assembly to automotive, logistics, and general manufacturing.

“As part of ABB’s OmniCore controller family, E10 and V250XT provide manufacturers with an expanded range of possibilities, enabling them to maximize their productivity and meet changing demands with minimum downtime,” says Matinlauri.

“The growing demands of the industry for quicker, more diverse production and greater responsiveness to changing market conditions calls for solution that bring new levels of speed, accuracy and flexibility,” says Antti Matinlauri, Head of Product Management for ABB Robotics.

Scalability and Connectivity

Both controllers offer increased scalability through the inclusion of over 1,000 hardware and software functions. These encompass areas such as programming, offline commissioning and simulation, maintenance, vision and safety.

The controllers also feature built-in connectivity to ABB Ability™ Connected Services cloud-based service suite for robots. With this feature they can offer new opportunities for improving performance through enhanced predictive maintenance and lifecycle management.

IoT Gateway

ABB has also introduced its IoT Gateway open automation software for OmniCore. IoT Gateway makes it possible to achieve truly joined-up production by enabling the seamless transmission of data from the factory floor, machine to machine (M2M), robots to other machines and robots to sensors, to the MES/ERP system, or to the cloud.

Motion Control Technology

Both controller feature ABB’s TrueMove and QuickMove motion control technology. It offers class-leading cycle times, high speed, position repeatability, and path accuracy. This enables ABB robots to operate faster than other robots in its class and up to 25 percent faster than their predecessors.

Slim Design

Featuring a slimline 19-inch rack-mount design, E10 is ideal for confined space and high-density production lines where space saving is a key requirement, such as small parts assembly and material handling in the electronics industry. The E10 controller is designed to power ABB’s SCARA robots and articulated robots with payloads of up to 11kg such as the IRB 920T and IRB 1300.

Suits Various Industries

Designed to power articulated robots with a payload of up to 300kg such as IRB 6700, the OmniCore V250XT controller offers a versatile and powerful solution for use in electric vehicle production, automotive manufacturing, logistics and general industrial applications.

Power Efficient

The OmniCore E10 and V250XT controllers consume up to 20 percent less energy compared to ABB’s previous IRC5 controllers. The energy-saving power re-generation technology and brake energy recovery makes this possible. They enable manufacturers to cut their energy costs and improve energy efficiency by contributing towards overall reductions in energy consumption.

FlexPendant Hand-Held Controller

Both controllers are used with ABB’s FlexPendant hand-held controller. The large 8” multi-touch display supports standard gestures, such as pinch, swipe, and tap, simplifying robot programming. FlexPendant is “hot-swappable”, which means it can be unplugged or re-connected without interrupting ongoing production. This allows FlexPendant to be shared between multiple robots, accelerating robot deployment and minimizing costs.

OmniCore Family

The E10 and V250XT beefs up ABB’s OmniCore family, with 14 robots now benefitting from enhanced power and flexibility. All OmniCore controllers are based on ABB’s industry leading RobotWare operating system. The OmniCore controller family will be extended across ABB’s robot portfolio and more applications will follow into 2022.