ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Code Reader Deals Complex Traceability Methods

Traceability in food and beverage, pharmaceutical, and other manufacturing industries often requires code readers. As such, the purpose of which is to capture data quickly and accurately from a variety of code types in various locations on products and packaging.

To address multi-code reading and positioning problems, automation solutions provider Omron Automation Americas recently introduced the V440-F fixed-mount code reader. Moreover, this code reader simplifies applications with a single model.

Ease of Use for Manufacturers

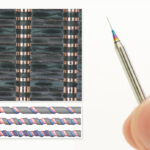

By reading multiple codes at once even as packages move by at speed, the V440-F helps manufacturers save on overall hardware costs and makes traceability easier to implement. Furthermore, the versatile industrial code reader has the mounting flexibility of a C-Mount vision sensor, allowing for short-, medium-, long-distance or wide-area configurations in a compact and cost-effective device. In addition, its high-speed processor can read up to 400 codes simultaneously.

In automotive assembly applications and robotic work cells, it is difficult to position a code reader in such a way that it does not interfere with the flow of operation.

The V440-F eliminates these positioning challenges with long-distance reading capabilities. Specifically, it positions at a safe distance from the operator/robot workspace. This long-distance reading is possible with a high-resolution image sensor combined with a lens selected for the appropriate distance.

Equally important, the V440-F expands upon the capabilities of Omron’s popular MicroHAWK Series with the new WebLink 3.0 browser-based interface that includes functions like “Matrix Mode” and “Ordered Output” for easily customizable data communication. Moreover, powerful X-Mode algorithms, also a feature of the MicroHAWKs, ensure even the tiniest of codes. Finally, it is possible to decode with ease those printed with blemishes or on challenging backgrounds.