ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yokogawa’s Unique Systems Secure Plants from Attacks

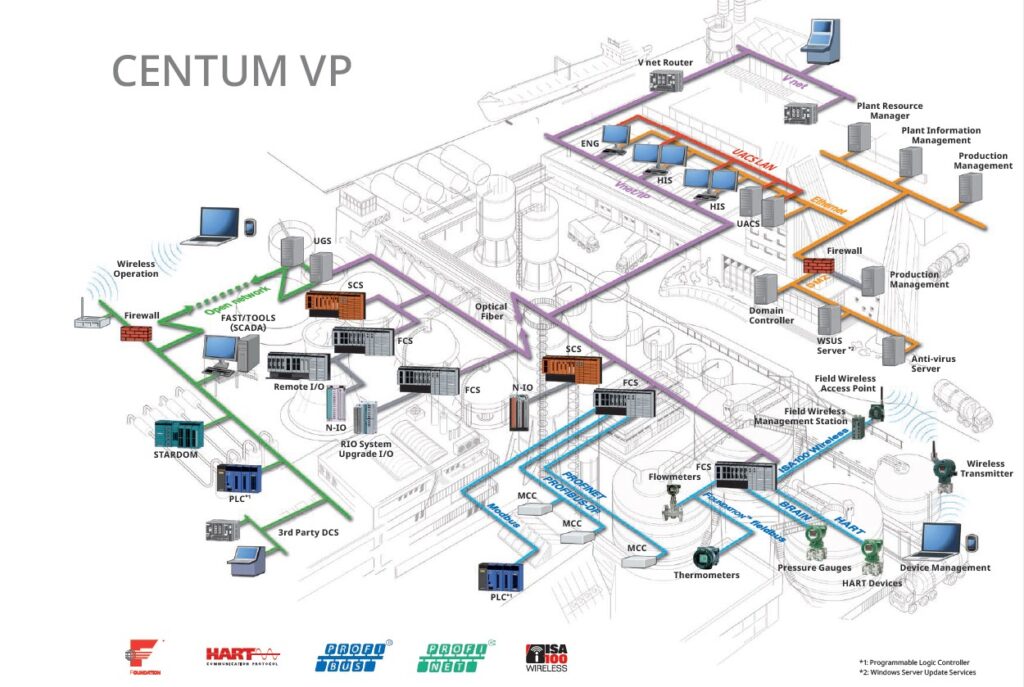

Yokogawa Electric Corporation has obtained ISASecure CSA Level 1 certification from the ISA Security Compliance Institute (ISCI) for its CENTUM VP integrated production control system. The system is a product in the OpreX Control and Safety System family.

As a result, Yokogawa’s CENTUM VP integrated production control system and ProSafe-RS safety instrumented system now both conform to the latest international security standards. In addition, the company has developed an enhanced version of ProSafe-RS Lite that meets both explosion protection and marine standards. At the same time, an updated version of the Plant Resource Manager (PRM) software that supports this latest version of the ProSafe-RS Lite.

Ensures Security of Industrial Automation, Control

Because of the growing need for remote system access, due in part of the prevailing COVID-19 pandemic, cyberattacks on production facilities are on the rise. Moreover, these attacks have grown more sophisticated. For that reason, awareness on systems that need to comply with international standards have grown as well.

Components that receive ISASecure CSA certification conform to the IEC 62443-4-1 and IEC 62443-4-2 international standards pertaining to security for industrial automation and control systems. The ProSafe-RS safety instrumented system, which conforms to safety integrity level SIL3, and the ProSafe-RS Lite, which meets SIL2 standards, obtained ISASecure CSA Level 1 certification in May and July 2021, respectively.

Optimizes Plant Safety

For CENTUM VP to qualify for ISASecure CSA Level 1 certification, a cyclic redundancy check function in the system periodically diagnoses the integrity of the programs and databases on a plant’s field control stations. An error detection will mean system alarm. Moreover, upgrading to the latest CENTUM VP R6.09 also enables operators to access Collaborative Information Server screens from their human interface stations. Consequently, this will enable the acquisition in real time of data on the operational status of equipment and devices.

In line with efforts to enhance safety, ProSafe-RS R4.07 has been developed, because of which ProSafe-RS Lite now meets both explosion-protection standards (ATEX/IECEx/ECAS-Ex) and marine standards. Therefore, installation of SIL2 system in plants and facilities where there is a risk of explosions is possible, as well as on LNG carriers and other vessels.

By using it together with the SIL3-certified ProSafe-RS, which also meets both sets of standards, it is possible to optimize the cost of plant safety instrumentation based on the application. In addition, PRM R4.05 has been developed to support devices that are connected to ProSafe-RS Lite. PRM uses IT to detect signs of impending equipment malfunctions, notifying operators and take preemptive action. Therefore, reducing the risk of failures.

With the development of highly secure and safe devices and systems, and the provision of support for their operation, Yokogawa can offer a wide range of control system solutions. The certification and functional enhancement of these solutions will contribute to safe and robust plant operations in many industries.