ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

1-Stop Smart Solution Optimizes Entire Factory

Yamaha Motor Co., Ltd. accelerates the proposal of 1-Stop Smart Solution for the entire factory under its surface mount technology (SMT) business. The company has added factory automation (FA) equipment and products of Yamaha Robotics Holdings Co., Ltd. (YRH) to its 1-Stop Smart Solution.

1-Stop Smart Solution

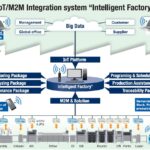

Yamaha Motor has been promoting 1-Stop Smart Solution in its SMT business. It combines its full-lineup system to Intelligent Factory, which is an internet of things (IoT) and machine-to-machine (M2M) integrated system.

The full-lineup system enables construction of a mounting line consisting only of Yamaha brand machines for the main equipment. These include mounters, solder printers, solder paste inspection (SPI) and automated optical inspection (AOI) systems, surface mount devices (SMD) storage systems (automated components warehouses), and dispensers. Meanwhile, Intelligent Factory manages the entire mounting line.

In its FA business, the company develops and manufactures various industrial robots needed in automated production lines, including single-axis robots, SCARA robots, articulated robots, and linear conveyers. It will also bring to market collaborative robots by the end of FY2022.

Ayako Egashira, Executive General Manager of Robotics Business Unit, Solution Business Operations, Yamaha Motor Co., Ltd., says, “Thus far, we have expanded our business taking advantage of our strength to construct SMT lines using only Yamaha Brand machines. From now on, we will promote 1-Stop Smart Solution by adding FA and semiconductor back-end process to SMT, eyeing labor saving and optimization of the entire factory.”

At NEPCON Japan 2022, Yamaha Motor set up a booth jointly with YRH. The company proposed the 1-Stop Smart Solution for the entire robotics business. The intelligent system achieves smartification of the semiconductor back-end process and the electronic components mounting process.

Reorganization of Robotics Business

Yamaha Robotics Holdings Co., Ltd. (YRH) is a group company of Yamaha Motor inaugurated in July 2019. It operates in the business area of merging semiconductor back-end process and the mounting of electronic components. YRH has as its group companies SHINKAWA LTD., APIC YAMADA CORPORATION, and PFA Corporation.

“Aiming to maximize the synergy effects of the three divisions, we have reorganized the Robotics Business Unit in accordance with functions. Under the new organization, we will expand sales through cross sell beyond the framework of products,” adds Egashira.

The organizational restructuring took effect on January 1 this year. The SMT Product Engineering Division, Development Division of the Factory Automation Section, and Advanced Engineering Division have been consolidated. This consolidation led to the creation of the Engineering Section. The Domestic Sales & Marketing Division and Overseas Sales & Marketing Division of the Surface Mount Technology Section, and Sales & Marketing Division of the Factory Automation Section have been consolidated. This led to the establishment of the Sales & Marketing Section. In addition, to optimize production activities through hastened planning of production and procurement, the company has also revisited part of the organization of the Manufacturing Section.

The company has intensified the deployment of showrooms. With that, it has put in place a system for the cross selling of the semiconductor manufacturing back-end process, SMT, and FA in Suzhou and Shenzhen in China, and in Taiwan.

Egashira says, “To capture needs of respective regions, we will further strengthen smart showrooms and laboratories in collaboration with YRH.”