ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

productronica 2021: Making Smart Factory a Reality

Productronica 2021, an international trade fair of manufacturing systems, will be held from Nov. 16 to 19 at the Munich Exhibition Center in Munich, Germany. Messe München GmbH organizes the event.

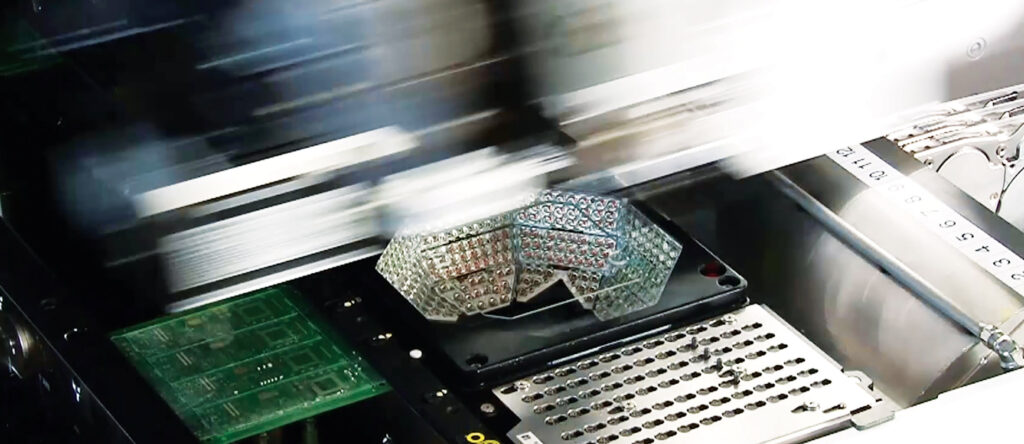

A wide array of products, equipment, and technologies in the field of electronics manufacturing will be at productronica. Among the prominent displays include semiconductors, surface mount technology, panels, light-emitting diodes (LEDs), photovoltaic power generation, micro-nano technology, clean room, material processing, printed circuit boards (PCBs), electronic manufacturing services (EMS), soldering materials and robots, tests and measurements, quality assurance systems, hybrid components, battery and electric energy storage, printing electronics, three-dimensional (3D) printing, and environment technologies.

European companies are expected to dominate the exhibition floor. Japanese companies will participate mainly through their local subsidiaries. Among them include ULVAC, Inc., Omron Corporation; Olympus Corporation; Canon Inc.; KOKI Co., Ltd.; Saki Corporation; SUMCO CORPORATION; Japan Unix Co., Ltd.; JUKI Corporation; Tamura Corporation; Nikon Corporation; Fujikin Co., Ltd.; Panasonic Corporation; FUJI Corporation; Yamaha Motor Co., Ltd.; Union Tool Co.; and RIKEN KEIKI Co., Ltd.

Latest trends in electronics manufacturing will take center stage at productronica 2021. (Image courtesy of FUJI Corporation)

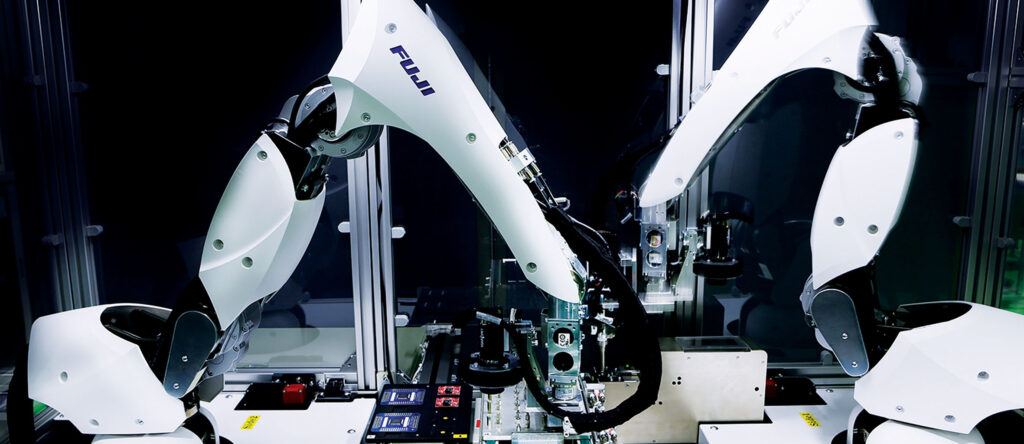

Advanced robotic systems play key role in PCB assembly. (Image courtesy of FUJI Corporation)

Fosters Automated Factories

Leading mounter manufacturers, like FUJI, Panasonic, Yamaha Motor, and JUKI will accelerate their proposals of smart factory solutions. They have been promoting automation and intelligent solutions, including pre- and post-processes of mounting.

In the manufacturing industry, needs for the automation of production and labor saving have been increasing amid rising labor costs and labor shortage. In addition, the COVID-19 pandemic has boosted interest in labor saving in production process to reduce human risk, as well as in full-automation and unmanned production. This trend holds true in mounting plants, and the spread of smart factories advance around the world.

Mounter manufacturers advance smart factories and promote the installation of digital twin technology. Digital twin makes use of simulation technology to mimic the existing surface mount technology (SMT) floor in the virtual space. It visualizes problems on the SMT floor by taking into consideration human’s workload, which was difficult to put into numerical values in actual operation. It is also possible to visualize the effects of installation of automation equipment and changes in operation.

In the SMT floor modelled in the virtual space, it is possible to set parameters for each process, such as the numbers of automated guided vehicles (AGVs) and component warehouses, number of workers, and production lines of workers, to confirm the effects of installation.

Industrial internet of things (IIoT) have been fundamentally changing the manufacturing of electronic devices and the preconditions of manufacturing. A smart factory, which digitally connects production equipment and value chain, is becoming a reality.

In the smart factory zone, visitors will see the measures being implemented by companies to solve problems, including optimization of manufacturing facilities, infrastructure and security of industrial information technology (IT). They will witness how manufacturers connect existing systems to the cloud, and other transmission and analysis functions.