ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Novel AI Proves Role in Autonomous Plant Operation

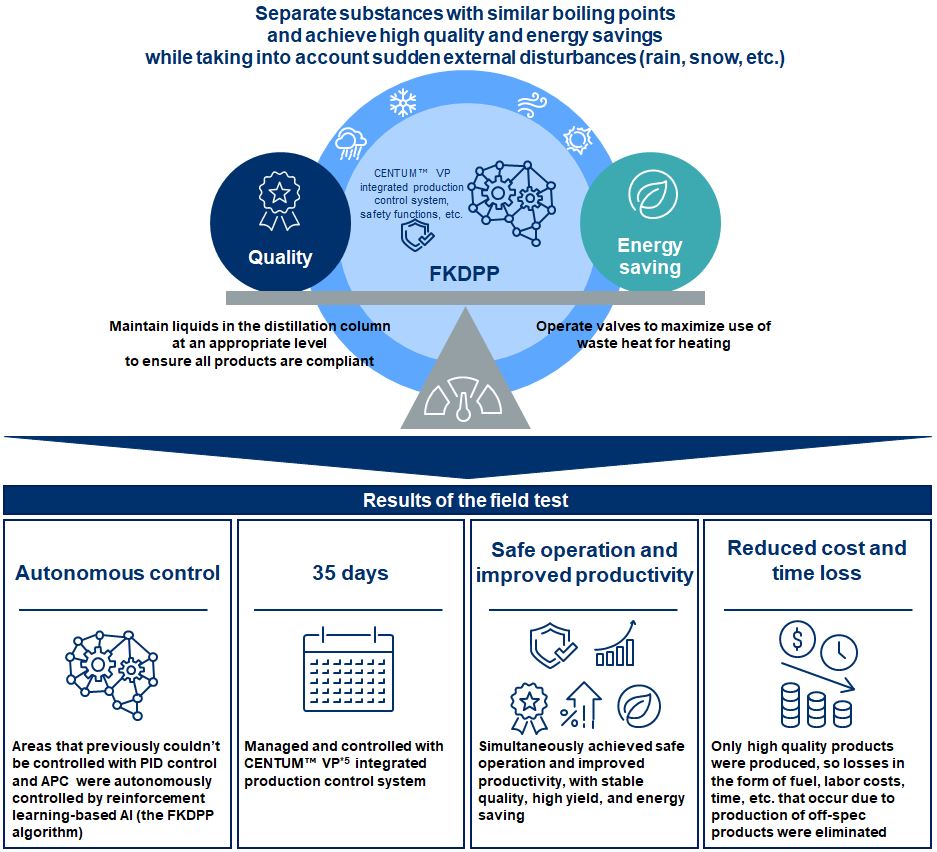

Yokogawa Electric Corporation and JSR Corporation have successfully concluded a field test that makes use of artificial intelligence (AI) to autonomously run a chemical plant for 35 days, a world first1. The test confirmed that reinforcement learning AI can be safely applied in an actual plant and demonstrated that this technology can control operations that have been beyond the capabilities of existing control methods (PID control2 and APC3). In addition, the test, have up to now, necessitated the manual operation of control valves based on the judgements of plant personnel. The initiative described here was selected for the 2020 Projects for the Promotion of Advanced Industrial Safety subsidy program of the Japanese Ministry of Economy, Trade and Industry (METI).

Control in the process industries spans a broad range of fields, from oil refining and petrochemicals to high-performance chemicals, fiber, steel, pharmaceuticals, foodstuffs, and water. All these entail chemical reactions and other elements that require an extremely high level of reliability.

In this field test, the AI solution successfully dealt with the complex conditions needed to ensure product quality and maintain liquids in the distillation column at an appropriate level while making maximum use of waste heat as a heat source. In so doing it stabilized quality, achieved high yield4, and saved energy. While rain, snow, and other weather conditions were significant factors that could disrupt the control state by causing sudden changes in the atmospheric temperature, the products that were produced met rigorous standards and have since been shipped. Furthermore, as only good quality products were created, fuel, labor, time, and other losses that occur when off-spec products are produced were all eliminated.

Ensures Safe Operations

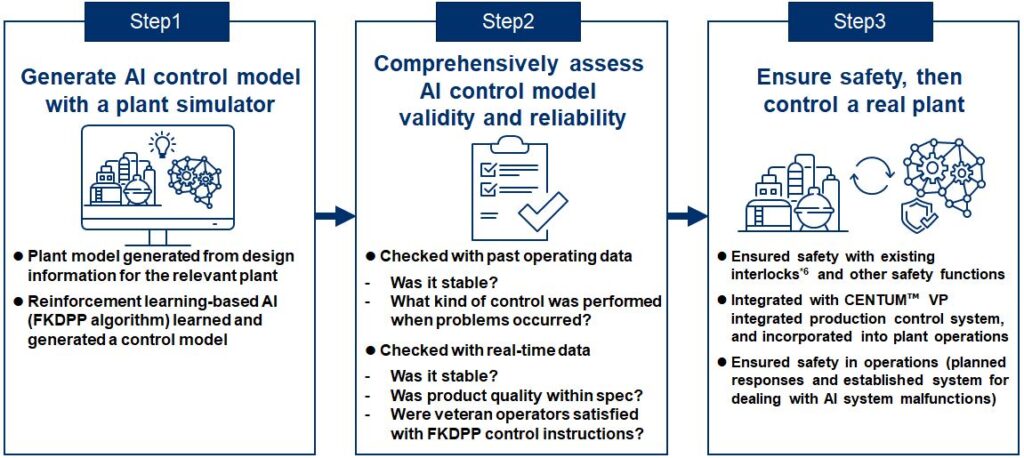

The AI used in this control experiment, the Factorial Kernel Dynamic Policy Programming (FKDPP) protocol was jointly developed by Yokogawa and the Nara Institute of Science and Technology (NAIST) in 2018 and was recognized at an IEEE International Conference on Automation Science and Engineering as being the first reinforcement learning-based AI in the world that can be utilized in plant management7.

Through initiatives including the successful conduct of a control training system8 experiment in 2019, and an experiment in April 2020 that used a simulator to recreate an entire plant9, Yokogawa has confirmed the potential of this autonomous control AI10 and advanced it from a theory to a technology suitable for practical use. It can be used in areas where automation previously was not possible with conventional control methods (PID control and APC), and its strengths include being able to deal with conflicting targets such as the need for both high quality and energy savings.

Given the numerous complex physical and chemical phenomena that impact operations in actual plants, there are still many situations where veteran operators must step in and exercise control. Even when operations are automated using PID control and APC, highly experienced operators have to halt automated control and change configuration and output values when, for example, a sudden change occurs in atmospheric temperature due to rainfall or some other weather event. This is a common issue at many companies’ plants. Regarding the transition to industrial autonomy11, a very significant challenge has been instituting autonomous control in situations where until now manual intervention has been essential. Moreover, in doing this with little effort as possible, ensures a high level of safety. The results of this test suggest that this collaboration between Yokogawa and JSR has opened a path forward in resolving this longstanding issue.

Digs Deep on AI’s Role

Yokogawa welcomes customers who are interested in these initiatives globally. The company aims to swiftly provide products and solutions that lead to the realization of industrial autonomy.

JSR believes that this demonstration shows AI’s potential for addressing challenges that previously could not be resolved at chemical plants. Furthermore, it will investigate its application to other processes and plants with the aim of achieving further improvements in productivity.

Going forward, the two companies will continue to work together and investigate ways in using AI in plants.

Masataka Masutani, General Manager of Production Technology at JSR, commented, “In an environment that is changing due to factors such as 5G and other developments towards a digital society, as well as the aging labor population, the petrochemical industry is under strong pressure to improve safety and efficiency in its production activities by utilizing new technologies such as IoT and AI. The orientation of JSR is toward making production smart through a proactive incorporation of drones, IoT sensors, cameras, and other new technologies, and in this experiment, we took on the challenge of the automation of plant process control using AI control technology.”

Masutani added that they have verified AI is able to autonomously control the processes that were previously performed manually based on operator experience. He added they are firmly convinced of the usefulness and future potential of AI control.

“From those in the field, we have heard comments saying that not only has the burden on operators been reduced, but the very fact that we have taken on the challenge of this new technology and succeeded is motivation for taking forward DX into the future. Henceforth, we shall expand operations controlled with AI, and work to enhance chemical plant safety, stability, and competitiveness.”

Towards Strong, Flexible Operations

Takamitsu Matsubara, Associate Professor at NAIST, remarked, “I am very glad to hear that this field test was successful. Data analysis and machine learning are now being applied to chemical plant operations, but technology that can be used in autonomous control and the optimization of operations has not been fully ready until now.”

Matsubara added the reinforcement learning of AI FKDPP algorithm, which was jointly developed by Yokogawa and NAIST in 2018, aims to realize autonomous control in chemical plants. Despite having to refer to many sensors and control valves, the AI can generate a robust control policy in a limited number of learning trials. These features helped to improve the efficiency of the development process and led to the achievement of autonomous control for a long period of 840 hours during the field test.

“I think this very difficult achievement of autonomous control in an actual distillation column and the fact that the level of practical application has been raised to the point where the entire production process and safety are integrated into one system have great significance for the entire industry. I look forward to seeing what happens next with this technology,” said Matsubara.

Yokogawa Electric Vice President and Head of Yokogawa Products Headquarters, Kenji Hasegawa, added, “The success of this field test came from bringing together the deep knowledge of the production process and operational aspects that only the customer can provide. In addition, Yokogawa’s strength of leveraging measurement, control, and information to produce value. It suggests that an autonomous control AI (FKDPP) can significantly contribute to the autonomy of production, maximization of ROI, and environmental sustainability around the world.”

Yokogawa led the world in the development of distributed control systems that control and monitor the operation of plant production facilities. Furthermore, it has supported the growth of a range of industries.

“With our gaze fixed firmly on a world of autonomous operation that forms the model for the future of industries, we are now promoting the concept of IA2IA – Industrial Automation to Industrial Autonomy. To achieve strong and flexible production that takes into consideration the impact of differences in humans, machines, materials, and methods, the 4Ms, in the energy, materials, pharmaceuticals, and many other industries, we will accelerate the joint development of autonomous control AI with our customers around the world,” added Hasegawa.

Notes:

*1 Based on Yokogawa Electric survey conducted in February 2022 regarding AI that directly changes the manipulative variable in the chemical plant.

*2 Proportional-Integral-Derivative control. First proposed by Nicolas Minorsky in 1922, this is an infrastructure control technology for processing industries that is used to control items such as quantity, temperature, level, pressure, and ingredients. It implements control toward a target value while using the results of each of the P, I, and D calculations according to the deviation between the current value and the set value. There are issues with this mode of control such as an inability to deal with multiple external disturbances (weather, climate, material composition changes) and frequent changes to target values, thereby necessitating manual control.

*3 Advanced Process Control. This uses a mathematical model that can predict process responses and gives set values to the PID control loop in real time in order to improve productivity, quality, and controllability. It is also easily applied to control for the purpose of increasing production, reducing labor time, and saving energy. Incorporating APC results in smaller deviations in data, making it possible to get closer to the limits of operating performance (i.e., the state in which the optimum performance can be obtained). However, it is limited by the fact that it is not adept at responding to the rapid vaporization of fluids and other such chemical reactions, major changes in material composition, and changes in machinery.

*4 The volume of the target substance that is actually obtained from raw materials through the refinement process

*5 The CENTUM VP integrated control system allows the entire production process to proceed while monitoring and controlling pressures, flow rates, temperatures, and other such factors, as well as integrating various interlocking functions for safe and stable operation and accident prevention. To prevent plant accidents, it is possible to operate in cooperation with safety instrumented systems (SIS), emergency shutoff devices (ESD), fire protection systems (F&G), etc.

*6 A mechanism that prevents startup unless certain conditions are fulfilled prior to operation. It increases safety by preventing incorrect operations, procedural mistakes, and the like.

*7 Factorial Kernel Dynamic Policy Programming for Vinyl Acetate Monomer Plant Model Control, August 2018. https://ieeexplore.ieee.org/document/8560593/ . The IEEE (Institute of Electrical and Electronics Engineers) is a US-based academic research and technical standardization organization that focuses on the fields of electrical and information engineering. It has more than 400,000 members in 160 countries around the world.

*8 A three tank level control system that is used to perform training and experiments involving the regulation of the flow of water from one level to the next, with the overall aim of controlling the water level at the lowest stage. It also includes devices to artificially create disturbances that randomly change the flow of water. Given the nature of fluids, the control of their flow rates is a difficult challenge in the processing industries. Being able to adequately perform this control leads to increased productivity at manufacturing sites.

*9 Scalable Reinforcement Learning for Plant-wide Control of Vinyl Acetate Monomer Process, Control Engineering Practice, Volume 97, April 2020 https://www.sciencedirect.com/science/article/pii/S0967066120300186

*10 Yokogawa defines autonomous control AI as AI that deduces the optimum method for control independently and has a high level of robustness enabling it to autonomously handle, to a certain extent, situations that it has not previously encountered.

*11 Industrial autonomy is defined by Yokogawa as follows: “Plant assets and operations have learning and adaptive capabilities that allow responses with minimal human interaction, empowering operators to perform higher-level optimization tasks.” In the responses to the Global End-User Survey on the Implementation of Industrial Autonomy carried out by Yokogawa in 2021 covering 534 decision makers at 390 manufacturing companies, 42 percent said that the application of AI to plant process optimization will have a significant impact on industrial autonomy in the next three years.