ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Epson Robots Deliver Next-Level Performance, Flexibility

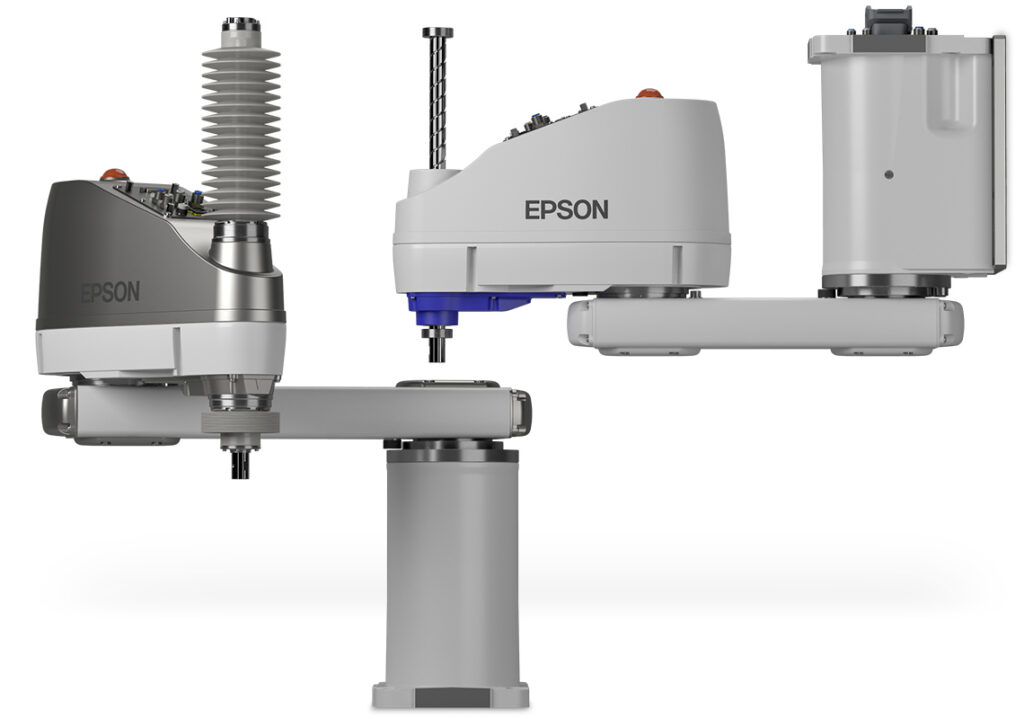

The demand for robotics is on the rise as businesses look to automation for productive manufacturing solutions. Against this backdrop, Epson Robots, one of the leading SCARA robot manufacturers, has announced the new GX Series robot lineup with the GX4 and GX8. Epson Robots are engineered to meet unique automation needs across various industries.

Built upon 40 years of expertise, the GX Series is a new class of high-power-density SCARA robots. They deliver next-level performance and flexibility ideal for medical device, electronics, and consumer electronics industries.

The GX robots will be showcased for the first time at Automate in Detroit, Michigan, from June 6 to 9.

Epson GYROPLUS Technology

The GX4 and GX8 SCARA robots offer high throughput, smooth motion control and heavy payloads with advanced Epson GYROPLUS technology. Both robots offer multiple arm configurations – a 250 to 350mm reach with the GX4 and a 450 to 650mm reach with the GX8. Thus, they can achieve ultra-high precision with tasks, including assembly, pick and place and intricate small-parts handling processes. Moreover, they have battery-less encoders, built-in Ethernet cables, and other advanced features to support a remarkably low cost of ownership.

“As the demand for automation continues across all industries, Epson pushes the envelope by providing high-performance solutions with leading-edge precision to meet the most demanding tasks,” said Scott Marsic, group product manager, Epson Robots.

“With the new GX Series, the GX4 and GX8 SCARA robots allow users to manage robotic solutions powerfully and with a compact footprint. Integration with Epson RC+® software helps manufacturers get the most out of their robots in terms of simplicity and performance,” Marsic continues.

Full-Packed Features

Varied Payload Capacity

The high-power density SCARA robots are equipped with larger motors to handle heavy workloads at fast speeds. Individually, GX4 can handle payloads up to 4kg and GX8 can handle up to 8kg, both from a small form factor.

Ease of Use

Equipped with Epson RC+ industrial automation development software, GX4 and GX8 offer ultimate ease of use. An intuitive and feature-packed software, Epson RC+ streamlines automation to effortlessly design complex and robust robotic solutions with a simple interface, advanced integrated solutions, and advanced 3D simulator.

Low Residual Vibration

Additionally, the two robots feature low residual vibration. They deliver fast settling times with proprietary Epson GYROPLUS vibration reduction system and rigid arm design, plus no ringing or overshoot. Both have optimized footprint designs with multiple mount and cable bottom exit options.

More Features

Specifically, GX4 offers optional features, like 250, 300 and 350mm reach and a unique curved arm (350mm) to maximize work envelope. Meanwhile, GX8 offers 450, 550 and 650mm reach and a longer Z axis as an option.

They are built for demanding environments, that is, standard, cleanroom (ISO3) and ESD. New standalone ESD models are also available. Specifically, GX8 supports Protected IP65.

Both robots feature advanced integrated options, including Vision Guidance, Parts Feeding, Force Guidance, Conveyor Tracking, Fieldbus, API.NET, and Arm Length Calibration.