ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Automation Technology Fortify Predictive Analytics

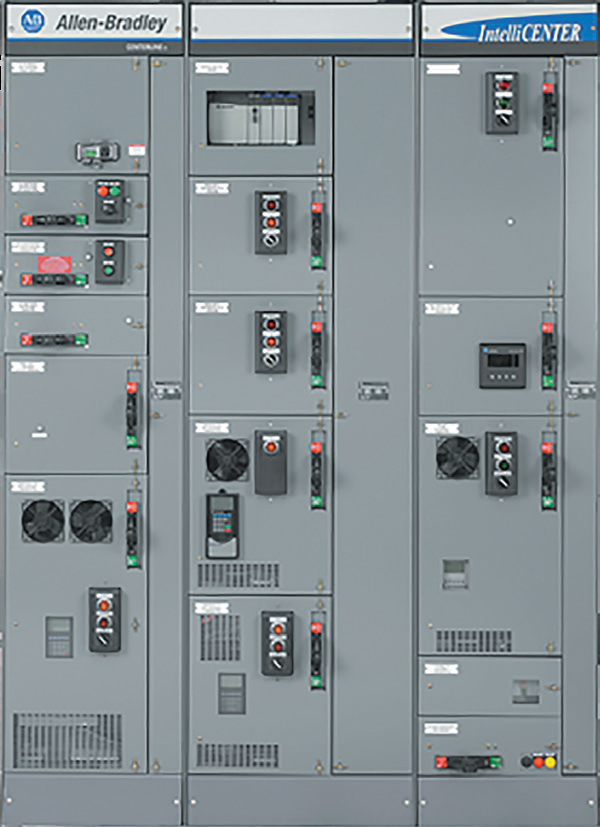

To boost manufacturing uptime, providing real-time predictive analytics, operational intelligence, and high-performance motor control are crucial. For that reason, Rockwell Automation has configured its CENTERLINE 2100 motor control center (MCC) with a new PowerFlex 755TS variable frequency drive.

CENTERLINE 2100 motor control centers provide power and process control into one centralized package. By integrating motor control and power in an MCC, manufacturers increase safety, productivity and reliability. In addition, with remote monitoring and control features, CENTERLINE MCCs offer enhanced safety features to help protect personnel and equipment.

Reduces Downtime, Propels Savings

Designed for demanding industrial motor control applications, Rockwell Automation’s new PowerFlex 755TS drives come with patented TotalFORCE control. To illustrate, this technology delivers real-time predictive analytics.

In addition, among other features of the new PowerFlex 755TS include automated commissioning, adaptive control, and high-performance motor control. These keep operations running at peak performance.

As a result, this industrial automation solution helps increase uptime and boost productivity from existing operations. Moreover, it also helps reduce energy and maintenance costs and increase safety.

In industries where downtime can cost thousands of dollars per hour, real-time data from this smart technology delivers peace of mind. Furthermore, it can also deliver ROI in energy savings in as little as six months.