ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Nireco’s New Inspection Tool Boosts Battery Production

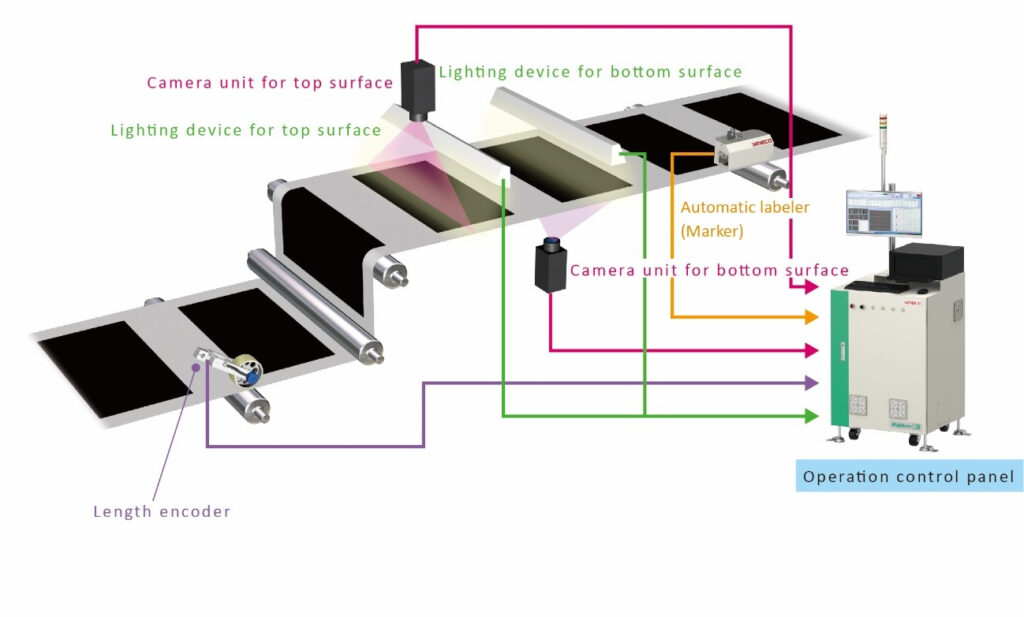

Nireco Corporation has developed a new electrode sheet inspection system, the Mujiken-RB. To illustrate, the system enables inspection and measurement on production lines for positive and negative electrode materials of rechargeable batteries.

Of late, there has been rising global concern for the environment. For that reason, demand for rechargeable batteries for electric vehicles and other applications has dramatically increased. Hence, a continuing expansion of production systems for these batteries.

High Speed, High Accuracy

The newly developed Mujiken-RB enables improved high-speed and high-definition inspection and measurement over existing inspection systems. Particularly, they employ an exclusive high-speed camera and high-speed image processing engine to improve inspection efficiency in electrode sheet production lines.

In the production of cathode and anode materials, which are essential components of rechargeable batteries, inspection machines with high speed and accuracy are necessary. This is to insure the high reliability of these materials in end products.

The Mujiken-RB is the latest electrode sheet inspection system in Nireco’s Mujiken series. The series, introduced in 2009, has a proven track record of delivering inspection systems that meet customer needs for improved production efficiency.

It includes the functions of an existing Nireco system, the e-FlexEye-RB2, such as inspection of coated and non-coated area defects of coating patterns. In addition, other functions include simultaneous inspection of front and back surfaces, while also incorporating a new type of image processing board and a camera.

The new board and camera enable up to nearly four times faster line speed and up to four times higher resolution inspection at current line speeds compared with the e-FlexEye-RB2. Moreover, the measuring function achieves higher accuracy and has both the productivity and accuracy required for electrode sheet production lines.

Established in November 1950, Nireco’s main business field is development, manufacturing, sales and maintenance services for control and inspection equipment. The company has capital of ¥3.07 billion (US$22.5 million) and had consolidated sales of ¥8.117 billion in FY2022/03.