ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

3DLiDAR Enables More Accurate, Complete Factory Automation

Discrete process factories have been installing leading-edge machine tools targeting to improve quality and yield of products. Particularly, equipment design engineers use equipment design simulator to achieve optimum arrangement of equipment taking into consideration connection sections between units and interference sections with things.

In this article, Nomura Research Institute discusses the role of high-precision 3DLiDAR in realizing fully automated factories and greater man-machine collaboration.

Challenges in Fully Automating Production Processes

However, installation and operation of equipment, there are not a few cases that deviation occurs in absolute coordinates. Moreover, the moving part does not reach the assumed position.

For example, the actuator does not reach the initially expected location due to slip loss in the wheel portion of a robot such as an AMR (Autonomous Mobile Robot) or a decrease in outer diameter due to tire wear. A factor for these phenomena is the simulator, which does not reflect expansion and contraction of objects according to temperature conditions, and physical loss. Currently, when the above problems occur, the line is stopped and the steel sheets and machines are moved manually.

Digitization of Coordinate Data in Real Time

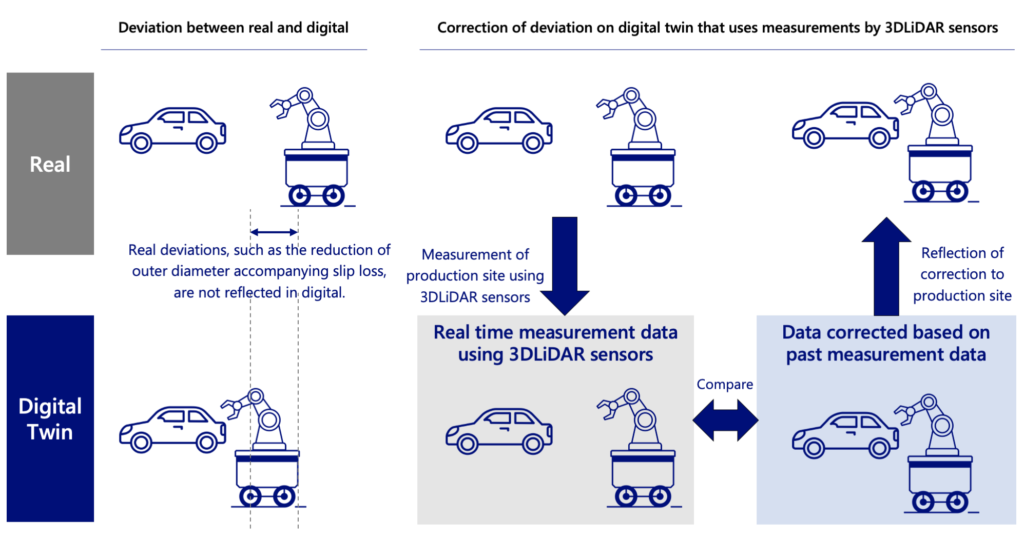

To solve these problems, first, it is necessary to grasp the precise positioning and shape of the on-site equipment when it is operating normally. Then, a system is needed to identify in real time any gaps in slight coordinate deviations/shape changes and, based on comparisons with the original data, to provide alerts before a short line stoppage occurs (Figure 1).

This will make it possible to realize an optimal production system based on real-time correction in accordance with the state of equipment in the factory.

Digital twin systems that digitally reproduce the operating conditions of each facility and product in real time have been considered in the past, but a factory digital twin system that combines these systems to realize optimized production will become possible.

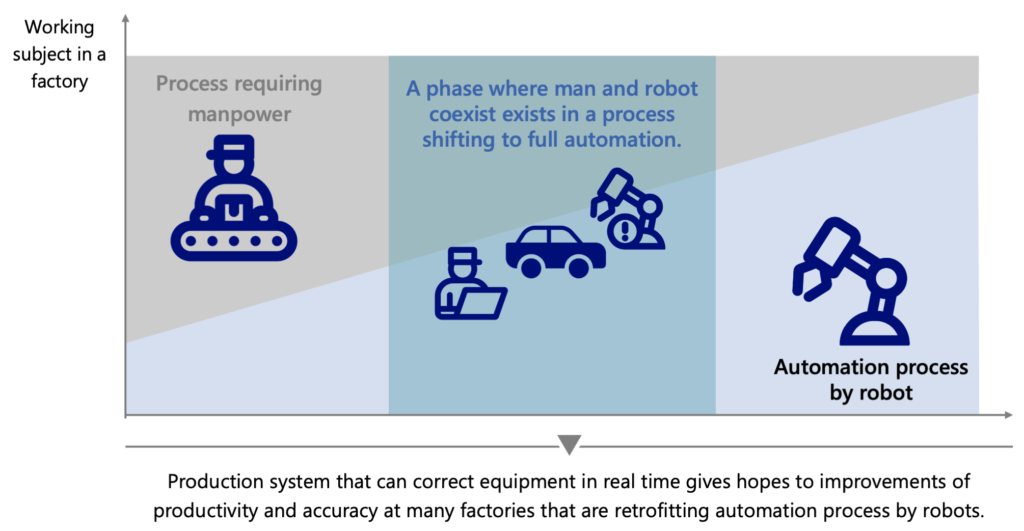

In particular, in cases such as many factories in Japan, where automation is added to existing facilities (i.e., where processes that require manual labor are mixed with automated processes), such measures are extremely important for improvement through the use of automation (Figure 2). Thus, the case of many factories in Japan.

Line Design, Predictive Maintenance Using Measurements by 3DLiDAR

In order to realize the above mechanism, measurement of objects by 3DLiDAR is considered effective: objects measured by 3DLiDAR are recorded as digital data, and the displacement between observation points can be accurately determined in real time. If it is possible to detect differences in expansion rates of a few millimeters or slight misalignment in three dimensions compared to the original data, it will be possible to detect anomalies and physically correct them before the equipment stops.

Furthermore, LiDAR sensors detect deviation degree from original data. Hence, they can detect abnormalities with no learning and accumulation of data like status monitoring by cameras. This is the strength of LiDAR sensors.

In fact, Lattice Technology Co., Ltd.(*) and TAIHO SEIKI CO., LTD. have jointly developed a simulator, which measures entire facilities using 3DLiDAR sensors, and uses obtained point group data to design equipment. The simulator has a function to highlight problematic point at the occurrence of an error. For the future, the companies are planning to use the simulator for failure prediction and predictive maintenance.

Man-Machine Collaboration Towards Monodzukuri

In recent years, variations of products have increased, and trend is toward build-to-order (BTO) production to meet customers’ requirements, and variable-mix production. In addition to cell production system, dynamic cell production system starts to get underway.

In the dynamic cell production system, AMRs carrying components and equipment necessary for each process move among units and implement assembly work at each unit. Furthermore, there is a need to consider production order. In such production style, AMRs carry equipment.

In this production system, location of equipment is not fixed, necessitating simulation to grasp accurate locations of equipment and components and materials linked to data on actual items taking into consideration the moving routes of equipment, components, and materials. At this time, optimum production that suits conditions at that time becomes possible by obtaining detailed 3D data of actual items and frequently comparing them with the latest conditions.

Furthermore, if real-time grasping of conditions on the production floor becomes possible, machines can operate optimally in accordance with works done by humans.

These functions lead to the construction of production process capable of both free production with know-how and efficient and low-cost production using robots. For factories in Japan that faces depopulation to continue producing high-value-added high-mix production, collaboration of people and machine is necessary in a production system.

Note:

(*) Lattice Technology Co., Ltd. is headquartered in Tokyo, and develops XVL ultralight 3D format technology, which forms basic technology for solutions using 3D data. The company also develops and sells related software and provides solution services and consulting services.

About This Article:

The author is Ion Yasumori, Global Manufacturing Industry, Consulting Department, Nomura Research Institute, Ltd.