ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

OMRON Unveils New Automation Controller

OMRON Corporation is set to release the new NX Series NX502 CPU Units, automation controllers with advanced information control and safety control, and the NX-EIP201 EtherNet/IPTM units. Accordingly, the new products is set for global launch on April 24.

With the growing importance of ESG management, efforts to achieve carbon neutrality are becoming more active at manufacturing sites. In addition, manufacturing sites involved in products that are undergoing remarkable technological innovation, such as xEVs and digital devices, are facing challenges. Particularly, in building lines that can respond to rapid yield improvement and flexible equipment design to respond to sudden fluctuations in demand.

The NX502 CPU Units and NX-EIP201 EtherNet/IP Units utilize OMRON‘s unique advanced information processing, communications technologies, and large capacity memory to realize real time analysis and process modularization*1. Hence, contributing to the reduction of resource disposal losses at production sites and the shortening of lead times when changing lines.

Main Features

World’s highest precision*2 data collection and large-capacity transfer capabilities reduce resource disposal losses at production sites

The new controller has high-precision data collection capability with a jitter of 1μsec or less and data transfer capacity approximately four times that of equivalent class controllers*3. For that reason, production-related data can be analyzed and reflected in processing conditions in real time. In addition, it realizes rapid improvement of processes that cause defective products and reduces resource disposal losses at various production sites.

Application example includes crystal manufacturing process required for precise product processing. In order to produce high quality crystals, production-related data must fluctuate in real time depending on conditions. Furthermore, there is a problem that manufacturing quality is not stable due to the limitations of communications performance.

Hence, the high information processing capability of the NX502 enables early identification of the cause, which leads to improvements in production conditions and contributes to stable mass production of crystals.

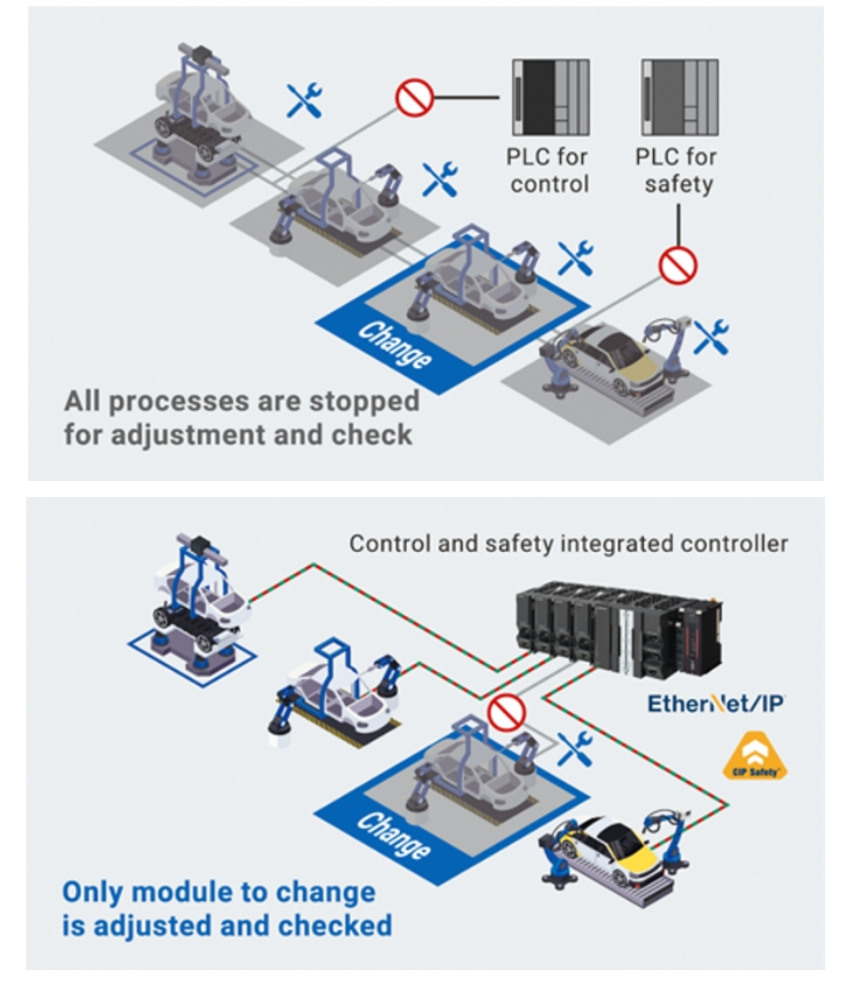

First integrated control technology*4 for large-scale and high-speed safety reduces lead times when changing production lines

The integrated control technology advanced by the NX502 and NX-EIP201 allows control large-scale production lines with module division. This is possible through up to 8 network system separations and up to 254 safety connections*5. Hence, enabling to adjust and check partial processes with minimal impact on overall operations even on large lines and maximizes energy productivity by significantly reducing lead times when changing lines.

An application example is the body frame welding line handling wide variety of products. Accordingly, the diversification of market needs, when it is necessary to add or change processes while mixed production of various vehicle models is becoming a requirement. In addition, it is necessary to minimize lead time by stopping only the relevant parts.

The NX502 and NX-EIP201 can separate network systems, including safety. Thus, can flexibly respond to detailed changes in manufacturing sites, such as the addition of welding processes, and contribute to improving production efficiency.

OMRON has been contributing to the improvement of productivity at manufacturing sites by leveraging its strength in control technology under the Innovation Concept innovative-Automation. Accordingly, the company aims to achieve sustainable manufacturing sites such as carbon neutrality in production in addition to improving productivity at manufacturing sites. OMRON will enrich the future for people, industries and the globe by innovative automation.

Notes:

*1: Modularization means dividing each process in the production line into functional units and making it easy to change flexibly.

*2: Based on our research as of March 31, 2023.

*3: Comparison with the NJ501. Based on our research as of March 31, 2023.

*4: OMRON’s unique multi-core technology simultaneously realizes information processing, safety processing, and control.

*5: Safety communications standards “CIP Safety™” and “FSoE (Safety over EtherCAT®)”.

- – EtherCAT®, Safety over EtherCAT®, are trademarks or registered trademarks, licensed by Beckhoff Automation GmbH, Germany

- – EtherNet/IP™ and CIP Safety™ are trademarks of ODVA.