ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Imaging Technique, AI Automate PCB Inspection

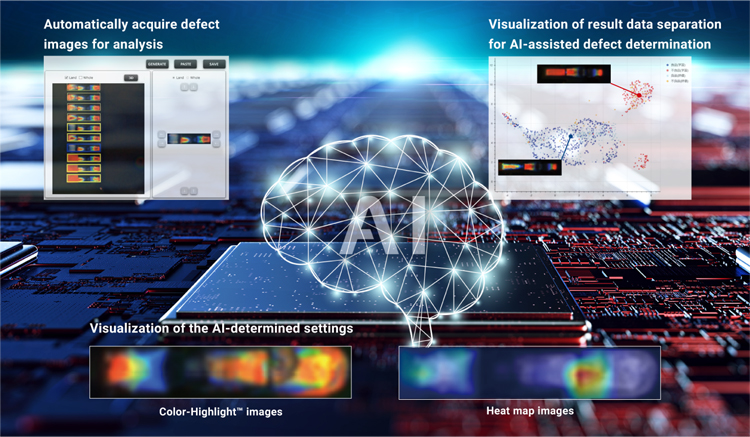

OMRON Corporation will release to the market the VT-S10 Series printed circuit board (PCB) inspection system that employs an industry-first imaging technique and artificial intelligence (AI) to automate high-precision inspection process for electronic substrates, thus eliminating the need for a specialist.

As the inspection of in-vehicle electronic substrates becomes increasingly difficult with the growing needs for the fifth-generation (5G) mobile communication system, electric vehicles (EVs), and autonomous driving, this new offering from OMRON performs high-precision inspection of such key components to maintain and enhance their quality, thus contributing to the security and safety of our society.

Address Manpower Issues

In recent years, the demand for electronic substrates for applications in 5G as well as in electric vehicles and autonomous driving has grown rapidly, which in turn is raising the quality requirements of substrates, since these applications involve risks to human lives. As substrates become more dense and miniaturized, inspection becomes more challenging, with the result that conventional PCB inspection systems struggle to take an accurate image of solder shapes, which limits the scope and parameters of inspection.

Meanwhile, on production floors, amid the growing shortage of skilled workforce and manpower in general, workers are required to avoid close contact and to limit their movement as they work to prevent the spread of COVID-19.

It has thus become necessary to reduce the frequency of visual inspections and lower the experience and skill requirements for setting and starting up automated inspection equipment, in addition to advancing inspection accuracy.

Expands Scope of Automated Production

Equipped with OMRON’s proprietary Multi-Direction Multi-Color (MDMC) imaging technique, the VT-S10 Series automatically optimizes irradiation angles, colors, and light intensity of illumination during inspection of substrates according to characteristics such as the shapes of electronic components and soldering` on the substrates, thus reducing the human-hours required for set up by approximately 70 percent. Furthermore, with the help of AI, the company’s accumulated knowhow in imaging in the field of automated inspection, as well as knowledge in solder inspection, OMRON’s PCB inspection system is capable of automating inspections that have hitherto had to rely on human senses, significantly improving inspection accuracy.

With its strategic concept of “innovative Automation” anchored on three Is comprised of integrated, which dwells on evolution in control; intelligent, which is drawn out on intellitence through ICT; and interactive, which deals with the fusion of man and machine.

OMRON is driving innovations on the production floor. Through the integration of the widest range of control devices and the use of AI fully versed in solder inspection, the VT-S10 Series is the latest offering from OMRON that embodies the “innovative Automation” concept.

Going forward, OMRON said it will continue to advance innovations in production floors along with its customers. By expanding the scope and parameters for automated inspection, it hopes to free operators from simple, monotonous tasks to a more creative work.