ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ATI, FANUC Advance Robot Automation in New Collaboration

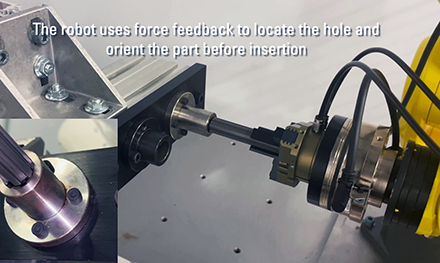

ATI Industrial Automation (ATI) has announced that its Multi-Axis Force/Torque (F/T) sensors are now compatible with FANUC robots and FANUC’s Force Control Software. This elevates FANUC users to a higher level of robot automation, offering increased precision, efficiency, and process control. Specifically, this groundbreaking collaboration opens doors to advanced automation and precision control, enabling more complex applications with ease.

ATI’s renowned Multi-Axis F/T sensors provide accurate measurements of forces and torques in multiple axes. Accordingly, they empower robots with a sense of touch and the capability to perform intricate tasks with precision. Designed to withstand harsh industrial environments, these sensors ensure reliable operation across a broad range of applications. Whether in research, medical applications, industrial operations, or even extra-terrestrial missions, ATI force sensing technology is revolutionizing the way robots interact with the world.

By integrating ATI’s advanced sensing technology with FANUC robots’ industry-leading performance and reliability, users gain unparalleled force control capabilities. FANUC’s Force Control Software enables precise control of robotic motion through real-time force feedback. Specifically, this function is perfect for assembly, deburring, polishing, and material removal tasks.

“We are thrilled to announce the compatibility of ATI’s Multi-Axis Force/Torque Sensors with FANUC Robots and FANUC’s Force Control Software,” said Robert Little, President and General Manager of ATI Industrial Automation. “This collaboration brings together two industry-leading solutions. Thus, it enables our customers to achieve new levels of dexterity, efficiency, and reliability in their robotic applications.”

Mainly, ATI and FANUC aim to provide comprehensive customer support. Specifically, they offer expertise in system integration to ensure a seamless implementation of this integrated solution. Together, they empower manufacturers and automation professionals to unlock the full potential of robotic automation.