ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

JETRO Taps Realtime Robotics for Investment Program

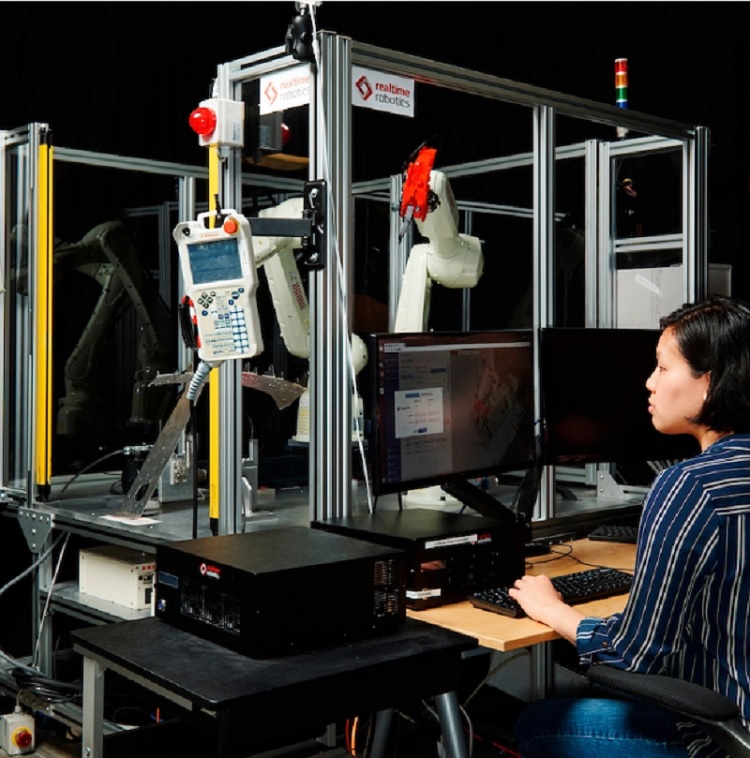

Realtime Robotics, the leader in collision-free autonomous motion planning for industrial robots, has announced that the Japan External Trade Organization (JETRO) has selected the company for a prestigious government subsidy program called the “Subsidy for Projects to Stimulate Direct Investment in Japan.” Primarily, JETRO’s selection of Realtime aims to expand the use of industrial robots and promote the standardization of system integrator operations.

JETRO is a government-related organization that works to promote mutual trade and investment between Japan and the rest of the world. Originally established in 1958 to promote Japanese exports abroad, JETRO’s core focus in the 21st century has shifted toward promoting foreign direct investment into Japan and helping small to medium size Japanese firms maximize their global export potential.

Currently, Realtime Robotics is developing a pair of robotics applications with key partners. Specifically, the development aims to make industrial automation easier and faster to deploy. These will be accelerated as a part of the JETRO program:

FANUC: Realtime Robotics is working with automation and robotics equipment partner FANUC on a plug-in. Specifically, it enables Realtime’s robot programming and motion control software, RapidPlan, to be operated directly within FANUC’s simulation software, ROBOGUIDE.

Specifically, the plug-in will allow users to configure a ROBOGUIDE as usual, including the layout, robot selection, and end-of-arm tooling. Then, users transfer it directly to RapidPlan. This makes it possible to send a sequenced list of positions necessary for robots to complete an application. Accordingly, RapidPlan can use to calculate optimal collision-free paths for the robots to execute. This eliminates the need for the tedious and repetitive manual analysis of robot motion paths traditionally required to insert waypoints or robot-to-robot interlocks in different parts of the program to avoid collisions.

DENSO: DENSO, a global production systems provider, is evaluating how Realtime Robotics’ RapidPlan can help improve its own flexible production units.

Denso’s multi-robot cell product, DX-CELL, helps manufacturers accommodate an increasing amount of variable product needs by making it easier to change the robot layout as needed. Denso expects that with RapidPlan, DX-CELL customers will be able to complete robot programming much more easily and quickly.

Also, Denso and Realtime are working to expand the collaboration to additional applications. These include multi-robot assembly, inspection, and bin picking. They believe improving efficiency will become even more important as the use of industrial robots expands across several different industries.

“It is an exciting time for manufacturing and robotics companies – and those who work with them,” said Koji Kobayashi, Vice President of Business Development, Japan at Realtime Robotics. “New, innovative technologies, such as our RapidPlan software, are opening the door to previously unheard of levels of automation efficiency and effectiveness. We’re thrilled to work with JETRO and partners such as FANUC and DENSO to transform what is possible within industrial robotics.”

For more information about Realtime Robotics’ innovative RapidPlan robot programming software and how it can help organizations improve the speed and accuracy of their automation operations, please visit: https://rtr.ai/meet-rapidplan/.