ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

OKI Zooms in on Polymers in New Evaluation Service

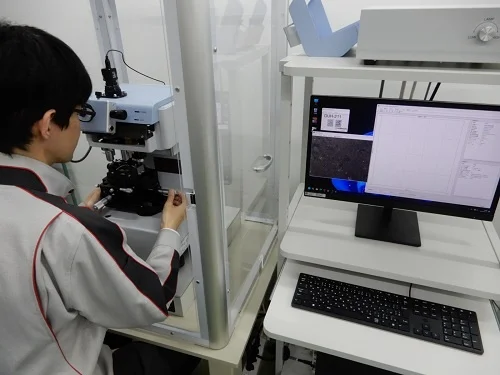

OKI Engineering Co., Ltd. provides reliability evaluation and environmental protection technical services for the OKI Group. It has announced it will expand its “Polymer Materials Deterioration Evaluation Service” from June 19. Mainly, the service will evaluate the chemical and physical deterioration of polymer materials such as resins and rubbers1.

Primarily, this will provide a one-stop service from degradation testing to characterization using environmental testing facilities. Additionally, it will support the adoption of polymer materials and the improvement of product durability by customers. OKI aims to achieve sales of 50 million yen (US$317,000) in FY2024 for the entire service, including testing and evaluation.

Along with the growing awareness for environmental protection, various industries are considering the use of sustainable materials2, including polymer materials. In the automotive field, the promotion of multi-materials3 has led to an increase in the evaluation of new materials. Thus, there is an increasing need to check the deterioration trend of materials. In addition, to shorten the development cycle of automotive products, there is a growing demand for services that provide end-to-end support from testing to deterioration evaluation.

Different Types of Degradation Tests

Until now, OKI Engineering has been providing degradation tests for polymer materials. These include ozone tests, weathering tests4, and chemical characterization by Fourier Infrared Spectroscopy (FT-IR5). In response to the need to check the deterioration trend of newly adopted materials, the company has added a thermal aging test that promotes thermal deterioration and a hardness measurement service that evaluates physical properties.

Targets One-Stop Service

Accordingly, this makes it possible to provide one-stop services from deterioration testing of polymer materials to physical and chemical characterization. Thus, it supports the efficient acquisition of evaluation data by customers and contributes to the shortening of material selection and product development cycles.

In the future, OKI Engineering will expand its various one-stop services, including deterioration evaluation services for polymer materials.

Generally, the company aims to realize a sustainable society through the provision of a wide range of services. Accordingly, it will contribute to the evaluation of sustainable materials for adoption in industries, in general, and in the automotive industry, in particular, as well as improving the durability of products.

Terminology:

1 Polymer materials – Also known as polymers, is a material that comprises large molecules in which many atoms are covalently connected. In general, resins and rubbers are polymer materials.

2 Sustainable materials – Materials that are environmentally friendly and have a low environmental impact.

3 Multi-material – A technology that combines materials with different characteristics in the right place or combines them to achieve higher strength and lighter weight.

4 Weather resistance test – To evaluate the resistance to degradation caused by the natural environment in a short time, an artificial light source that approximates sunlight is irradiated and intermittent water is sprayed.

5 FT-IR (Fourier Infrared Spectroscopy) – The sample is irradiated with infrared rays to obtain reflected or transmitted infrared absorption spectra. An analytical method that identifies the lineage of the components of a sample from the infrared absorption spectral pattern.

This is an online translation of a press release in Japanese.

-19 June 2024-