ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New FANUC 3D Laser Scanner to Optimize Robot Welding

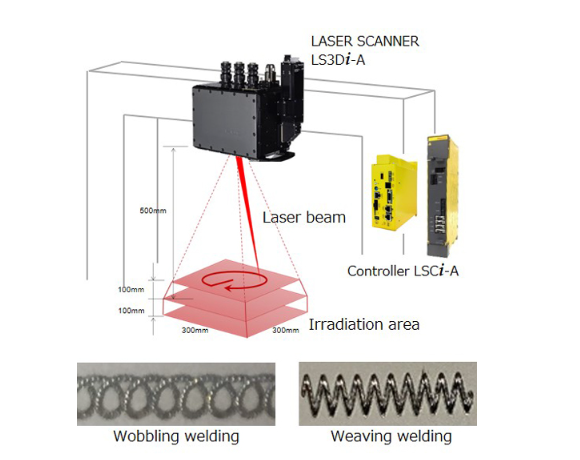

FANUC Corporation has released the new LASER SCANNER LS3Di-A as a single unit. Primarily, the 3D galvano-type LASER SCANNER LS3Di-A was developed based on FANUC servo motor control technology.

Key Features of LS3Di-A

The LASER SCANNER LS3Di-A can focus laser beams over a wide irradiation range from a long distance. Also, it can scan various shapes. This scanner finely oscillates X- and Y-axis mirrors that reflect laser beams with a two-axis motor by feeding back at high speed. Additionally, it can accurately irradiate laser beams in a range of 300 × 300mm.

Moreover, a motor controls the positioning of the focusing lens. This vertically adjusts the laser focal point with a span of ±100mm. Aside from 2D, 3D laser processing is also possible with the new product.

This scanner can be used in a wide range of applications, including laser welding of metal, cutting of metal foil or non-metal thin plates, and heating or removing coatings.

Taps LSCi-A Laser Scanner Controller

Using the high-speed control of the laser scanner controller LSCi-A, the scanning of laser focal points can be commanded with G code commands. This function specifies the X, Y, Z coordinates. Also, various CNC functions can be used simultaneously. For example, the processing commands for consecutive circular motion simplifies wobbling and weaving processing.

Moreover, LSCi-A is equipped with two-channel laser output control. Also, it supports the ring mode laser that changes the laser beam mode at the focal point. It also has a port for connecting measurement monitoring equipment that can detect welding point.

Optimize Welding Processes

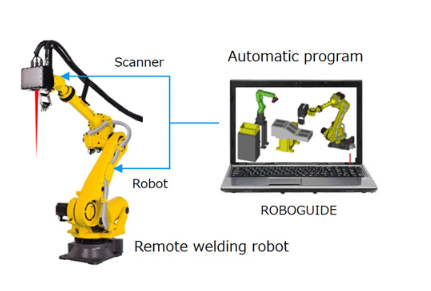

By installing LS3Di-A on the remote welding robot, optimal processing systems can be built up for the welding application of large workpieces, which exceed the irradiation range. Also, it enables continuous precision welding application of precise workpieces.

Meanwhile, the offline simulator ROBOGUIDE can be used to generate programs for both robots and scanners simultaneously. This way, the robot and scanner can coordinate their motions for laser machining.

The LASER SCANNER LS3Di-A can be applied to various applications. It can contribute to reducing cycle time and streamlining of production line processes.

-27 June 2024-