ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Hitachi, Sekisui to Surge New System for Recycling

Hitachi High-Tech Corporation, Hitachi, Ltd., and SEKISUI CHEMICAL CO., LTD. completed the proof of concept (PoC) of the Marketplace System for Recycled Materials. Accordingly, this will accelerate the use of recycled materials, which so far the companies confirmed its effectiveness.

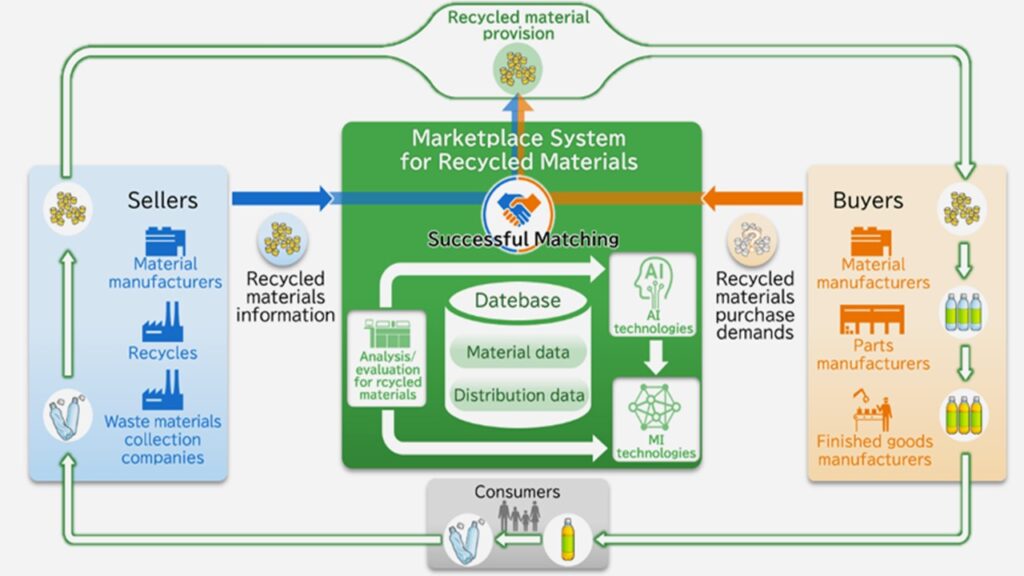

The system provides an online service that matches buyers looking to purchase recycled materials as raw materials and sellers looking to circulate waste as recycled materials. Thus, enabling a series of transaction processes.

Hitachi High-Tech and Hitachi are developing the system by using Hitachi High-Tech’s core technologies in measurement and analysis. Also, its extensive knowledge of plastic materials cultivated over many years. Meanwhile, the system is also utilizing Hitachi’s advanced digital technologies such as Materials Informatics (MI) and generative AI.

On the other hand, SEKISUI CHEMICAL provided waste materials generated in its own manufacturing processes to this PoC. This has significantly contributed to the development of the system. Moreover, this PoC successfully proved that the prototype of the system can smoothly establish a series of processes allowing product manufacturers (buyers) to consider adopting recycled materials processed from waste materials as raw materials.

As a result, the three companies will work together with the aim of commercializing a service that utilizes the system. Furthermore, it will promote active use of recycled materials in FY2025, achieving a circular economy and a sustainable society.

Background to the PoC

The circular economy has been attracting attention in recent years. For that reason, the demand for use of recycled materials is increasing. However, the quality of recycled materials from waste materials lacks stability compared to virgin materials*1 and the amounts produced are variable.

Therefore, it requires much expertise and a great deal of effort, also it can be challenging to match buyers of recycled materials with sellers. For example, buyers require information to locate and select a suitable recycler*2 and check the quality of recycled materials at risk of being contaminated with impurities. However, such information can be difficult to gather. Also, there are cases where sellers are unable to find a suitable buyer to use their recycled materials and eventually end up disposing of them.

Company Roles and the Details of the PoC

To combat these challenges, Hitachi High-Tech and Hitachi are working together to develop a system that will accelerate the use of recycled materials. Hitachi High-Tech is leveraging its extensive knowledge and network cultivated over many years as a specialized trading company.

In this way, Hitachi High-Tech provides expertise that contributes to solving the challenges of using recycled materials, such as material data, proposals for optimal conditions for recycled material formation processes and recycled material quality control. Hitachi has been developing the system using advanced digital technologies such as AI. Moreover, the knowledge and expertise gained through providing over 100 cases of MI solutions to more than 50 material manufacturers and other companies.

Hitachi has previously collaborated with SEKISUI CHEMICAL to drive advancements in MI, also in this PoC we are working together for aiming to develop the system.

Thus, SEKISUI CHEMICAL Group aims to contribute to realizing a sustainable society and has set the target of achieving a circular economy by 2050.

In this PoC, the quality and performance of recycled materials processed from SEKISUI CHEMICAL waste underwent evaluation using equipment such as Hitachi High-Tech analyzers. Hitachi then completed the PoC by uploading the quality and performance data of the recycled materials onto the system.

Main Features of the System

(1) Beginner-friendly matching support features that utilize recycled material expertise and generative AI.

This feature (patent pending) supports practical matching by recommending and providing information on making the most of recycled materials. This makes the matching simple even for the unexperienced person.

(2) Matching support features for professionals that utilize MI solutions

This feature (patent pending) supports customization of recycled material that satisfy users’ ideal material performance. Specifically, by leveraging Hitachi’s own collected measurement data on the material composition and performance of recycled plastics alongside expertise gained through providing MI Solution which is one of Hitachi’s Lumada*3 solutions. It is also possible to verify the feasibility of recycled materials prior to their development. Thus, making practical matching possible without precedent.

In addition, this feature can predict what the physical properties will be if additives are mixed in with recycled materials, or what characteristics there will be if the recycled materials are mixed with a certain percentage of virgin materials, thereby contributing to efficient development of R&D divisions, etc.

(3) Recycled material molding support and quality control, utilizing sensing, measurement and analysis technologies

In the case of molding recycled materials, there was often a lack of knowledge in areas such as material compounds and molding methods, which then required significant time for investigation and trial runs.

By extracting feature values*4 from the recycled material quality through Hitachi High-Tech and Hitachi’s sensing technologies. This feature helps to propose optimal conditions and reduce barriers to entry.

Notes:

*1Materials manufactured entirely from new resources.

*2A company responsible for processing waste produced by factories and ordinary homes into materials which can be used as a raw material, such as recycled plastic or chemical products.

*4A numerical value that quantitatively expresses the features and characteristics of data and objects being analyzed.

26 June 2024