ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Device Trends Thread on Modern Power Electronics

Japanese electronic component makers have been intensifying the technological development of their respective power supply-related products. Primarily, they are promoting the development of new products such as power electronic components and next-generation rechargeable batteries. Basically, they aim to respond to the shift to xEVs in automobiles. Also, they target the increasing current capacity of industrial equipment and renewable energy devices. Accordingly, they aim to contribute to higher current capacity and efficiency in power supply systems.

Moreover, they want to contribute to the stable supply and effective use of energy. Particularly, they plan to strengthen the technological development of power supply-related components that will help promote energy conservation and higher efficiency of equipment and devices, electrification of automobiles, and shift to renewable energy.

Many electronic component manufacturers exhibited at POWER SUPPLY JAPAN at TECHNO-FRONTIER 2024 held at Tokyo Big Sight (Tokyo, Japan) in July. They presented their latest power supply-related products and solutions.

TDK-Lambda

TDK-Lambda Corporation exhibited the EZA11K-SU Series operation optional unit under development. It is being developed as an HVDC solution for the renewable energy market. Specifically, it can handle high voltages of up to 1500V by operating up to six units. The EZA11K-SU will meet the demand for higher voltages in the renewable energy market. Further, it aims to contribute to the stable supply and effective utilization of energy in the shift to renewable energy. The company plans to start sales in October.

Nichicon

Nichicon Corporation introduced its new UBR Series lead-type aluminum electrolytic capacitors for high voltage input for communication base stations. The series is rated at 450V and guaranteed at 125°C for 5,000 hours. Compared to the existing UBT Series, the UBR Series has achieved 2.5 times longer lifetime and meets the needs of high temperature and maintenance free.

TOKIN

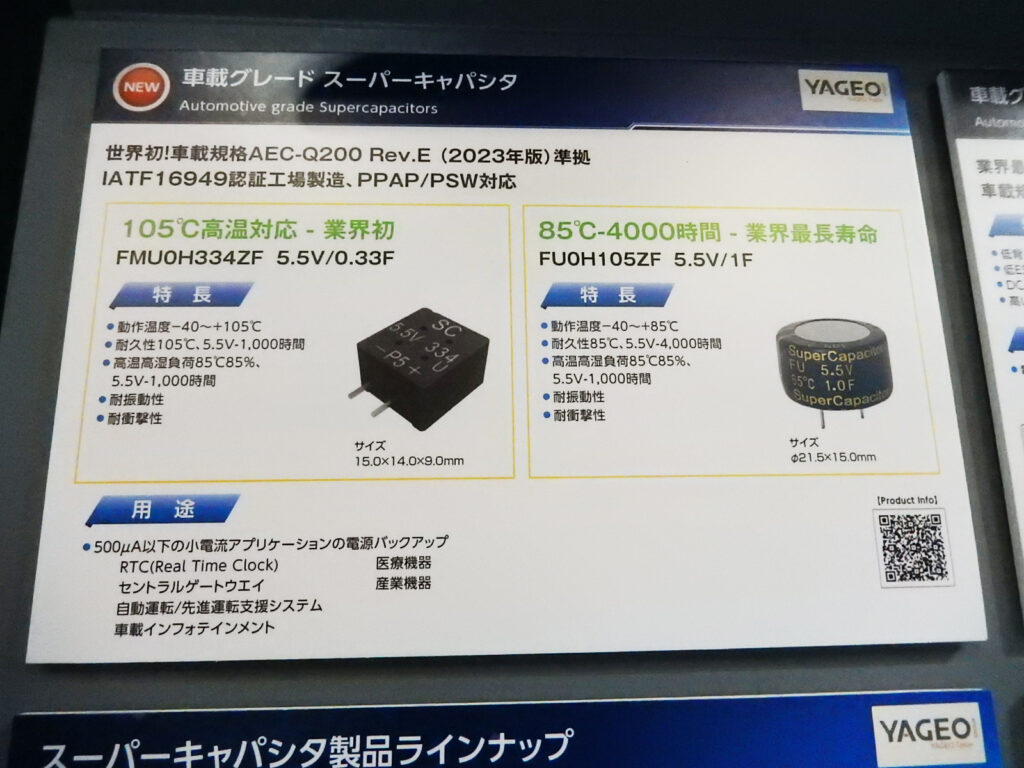

TOKIN Corporation has developed and exhibited 5.5V automotive-grade capacitors that comply with the AEC-Q200 Rev. According to the company, this is the first 5.5V automotive-grade capacitor compliant with AEC-Q200 Rev.E (2023 edition). The other two capacitors are the FMC0H334ZF 5.5V/0.33F, which is compatible with 105°C high temperatures, and the FU0H105ZF 5.5V/1F, which has the industry’s longest life of 4,000 hours at 85°C. TOKIN will propose these products for power supply backup in small current applications of 500µA or less, such as real-time clock (RTC), central gateway, automatic driving/ADAS, and in-vehicle infotainment.

SUMIDA

SUMIDA Corporation presented a reference exhibit of an electromagnetic induction coil module capable of non-contact power transmission of 3.6kW or more. This product is being developed for non-contact recharging of electric vehicles (EVs). It measures 60 × 60cm for the transmitting coil and 42 × 30cm for the receiving coil. The company aims to start mass production in a few years.

Suwa Sansha Electric

Meanwhile, Suwa Sansha Electric Co., Ltd. has begun selling the newly developed AD67 charge/discharge control unit, a standard product for various infrastructures. This product integrates a charge controller and various DC/DC units. Also, it achieves excellent charge efficiency through its unique MPPT control. Thus, it solves the problem of independent power supplies for outdoor use.

Rubycon

Rubycon Corporation has developed the new ZLR Series aluminum electrolytic capacitor lead wire type, featuring 105°C and long life, high capacitance, and low impedance. Compared to the existing ZLH Series, the ZLR Series has achieved the industry’s top specifications, with up to 40% higher capacitance, around 10% higher ripple, and lower impedance. Specifically, the ZLR uses a new high-performance electrolyte with improved high conductivity for low impedance, which, combined with a high hermetic sealing material, maintains long-life performance. Furthermore, the capacitor’s high capacitance is achieved by increasing the magnification of the electrode foil.

Maxell

Meanwhile, Maxell, Ltd. introduced an all-solid-state battery with high heat resistance of 125°C, long life, and high safety features for infrastructure and plant monitoring equipment. The company seeks applications such as IoT devices, monitoring equipment, and RTC/memory backup as next-generation power sources that support a sustainable society.

This translated article originally appeared in the Aug. 8 issue of Dempa Shimbun Daily.

-19 August 2024-