ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japanese Makers Unveil Latest in In-car Components

Setting sights on the popularization of next-generation automobiles, Japanese electronic component manufacturers are focusing on the technological development of in-vehicle electronic components and modules. Mainly, they promote technological proposals to meet future automotive needs. Among them are fully automated driving, high-capacity electric vehicle (EV), integrated ECU, improved comfort, and sustainability.

In today’s automotive market, technological and market structural reforms are accelerating, with “CASE” or connectivity, autonomous, shared and services, and electric, as a megatrend. In this context, Japanese electronic component companies are focusing on new products and technologies for the automotive market, particularly, for adoption in 2027 and beyond.

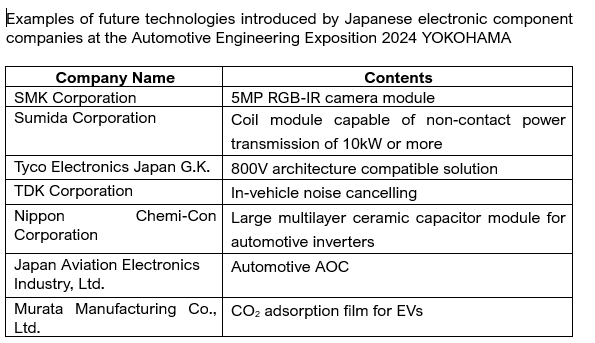

At the Automotive Engineering Exposition 2024 YOKOHAMA held at PACIFICO Yokohama from May 22 to 24, major electronic component companies introduced a broad list of new and future technologies. Particularly notable were proposals for changes in automotive architecture for fully automated driving and high-capacity EVs. Also, proposals for new mobility lifestyles in the era of automated driving, improvements in safety and comfort, and contributions to sustainability generated attention.

Japanese electronic component companies are also focusing on the development of new technologies to meet the increased communication capacity inside and outside the vehicle. Particularly, this is promoted by the Japanese government’s emphasis on software-defined vehicles (SDVs).

In-Car Noise Cancellation

TDK Corporation presented for the first time its In-Car Noise Cancellation system. This new system is being developed as a sound-deadening space solution. A thin and lightweight noise-cancelling piezolithon developed using piezoelectric speaker technology is mounted near the headrest of the seat. By reproducing waves in opposite phase, passengers can cancel in-car noise simply by sitting on the seat. The combination of piezoelectric speaker technology, MEMS microphones for sound deadening control, and digital signal processing for sound deadening space will enable efficient sound deadening with low latency.

The company has not yet decided when the system will be put to practical use. However, it will be widely proposed for next-generation automobiles.

Reducing the Occurrence of Drowsiness

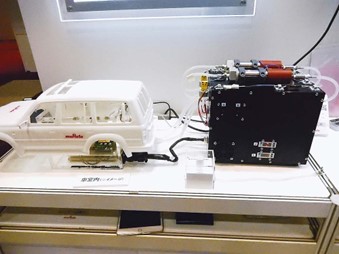

Murata Manufacturing Co., Ltd. also exhibited for the first time its CO₂ adsorption filter, currently under development. This product uses a honeycomb-shaped filter to adsorb CO₂ generated from human exhalation in the EV cabin. Thus, it reduces the CO₂ concentration and suppresses the occurrence of drowsiness.

Generally, the driving distance of an EV is shortened if the air conditioner is used while the vehicle is running. Therefore, the need to utilize internal air circulation when air conditioning is used, is anticipated to increase. However, this will increase the CO₂ concentration and may induce drowsiness. Therefore, the company proposes the adsorption filter as a countermeasure.

The filter material is a nano-porous material called MOF. According to the company, installation of a CO₂ adsorption filter with a diameter of about 30cm can adsorb all the CO₂ generated in a four-seater passenger car.

Eyes on BEVs

Tyco Electronics Japan G.K., a subsidiary of TE Connectivity, is strengthening its technological proposals for the 800V architecture. Particularly, this is a market seen to take off in Japan in the future with an eye toward full electrification (battery electric vehicles).

At the exhibition, TE Connectivity leveraged its extensive experience in the Chinese EV market to promote various 800V solutions.

Coil Module

Sumida Corporation exhibited for the first time a coil module capable of wireless power transmission of 10kW or more. Also on display is an electromagnetic induction coil module capable of wireless charging of EVs, measuring 60×60cm for the transmitter coil and 42×30cm for the receiver coil. While the coil module is still under development, the company aims to start mass production in a few years.

5MP Camera Module

SMK Corporation exhibited a 5-MP RGB-IR camera module for future in-vehicle monitoring, which simultaneously outputs RGB and IR images. It provides clear image data even for rear passengers thanks to its high resolution of 5MP.

-31 May 2024-