ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Hioki's New Tool to Surge R&D of EV Batteries

Hioki E.E. Corporation proudly announces the launch of its Powder Impedance Measurement System. Specifically, they suit electric vehicle (EV) solid-state battery R&D market.

Accordingly, this system significantly enhances the safety and cost-efficiency of material evaluation by enabling simultaneous measurement of key parameters. Most importantly, those essential for assessing solid-state battery materials and validating dry processes.

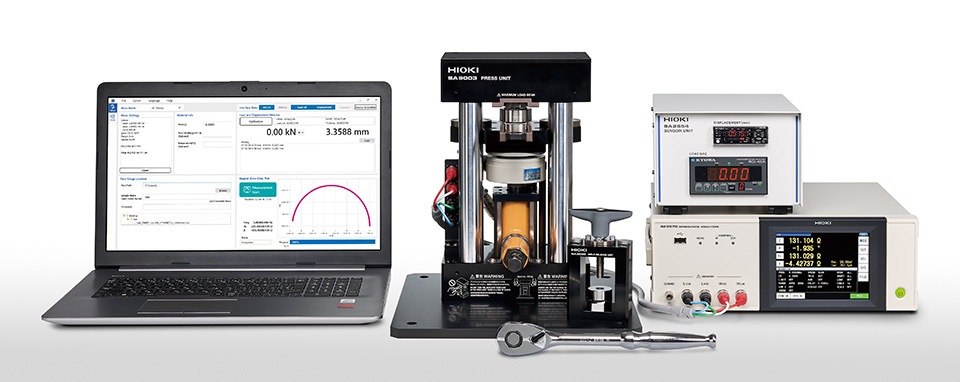

Featuring a compact press unit, multiple integrated measurement modules, and dedicated software. Moreover, the system operates entirely within a glove box (*1), improving work safety and reducing the risk of contamination. This innovative approach not only lowers evaluation costs but also shortens processing time. Therefore, allowing researchers to conduct more experimental trials.

With its enhanced operational efficiency and versatile capabilities, the Powder Impedance Measurement System is set to be a game-changer in advancing solid-state battery research for electric vehicles.

Development Background

Battery Electric Vehicles (BEVs) are a crucial solution for achieving sustainable global energy consumption. To support this, ongoing research focuses on developing next-generation batteries that enhance driving range, reduce charging times, lower vehicle costs, and improve safety. Among these innovations, solid-state batteries are emerging as a promising alternative to overcome current limitations.

Solid-state battery research explores various materials, such as sulfides, oxides, halides, and polymers.

Notably, sulfide- and halide-based solid-state batteries show high potential for early mass production due to their superior performance and the advantage of not requiring high-temperature processing during electrode preparation.

However, these materials demand-controlled environments for safe handling. For example, sulfide powders release harmful gases when exposed to moisture, requiring glove box setups. Similarly, halide powders need dry chamber conditions to prevent atmospheric degradation.

To address these challenges, Hioki has developed an all-in-one measurement system equipped with a compact press unit that fits inside a glove box. This system allows for simultaneous measurement of multiple critical parameters for material evaluation, ensuring the entire process, from sample preparation to measurement.

By supporting the development of solid-state batteries, Hioki aims to promote the widespread adoption of safe, high-performance, and sustainable BEVs, advancing the global shift towards renewable energy.

Product Features

Simultaneous Measurement of Impedance, Thickness, and Pressure

The SA9003 press unit, with a maximum pressing capability of 764 MPa and a 10 mm diameter electrode, reliably achieves the precise pressure levels required by customers.

This system allows for the simultaneous measurement of impedance, thickness, and pressure while controlling the compression state of the powder. Using these combined measurements, the integrated software can analyze and establish relationships between bulk density (2), ionic conductivity (3), and electrical conductivity. This contributes to the development of soft, adhesive, and crack-resistant solid electrolytes, and optimizes the positive electrode mixture ratios.

Compact Measurement System Optimizing Research Environment

The press unit is designed to be highly compact, allowing for easy installation within the glove box without occupying critical workspace. This setup ensures that materials remain inside the glove box throughout the entire process, from filling to compression and measurement.

Conducting experiments in this controlled environment protects researchers from harmful gas emissions, moisture-induced degradation, and reduces sample retrieval time.

Significant Reduction in Evaluation Costs and Increased Experimental Trials

Developing solid-state batteries requires extensive experimentation under varying conditions, such as different pressures and material mixing ratios. Traditionally, each sample had to be removed from the glove box for characterization after compression, consuming a separate sample for each condition.

Hioki’s Powder Impedance Measurement System streamlines this process by performing all tasks within the glove box, significantly improving operational efficiency. With the integration of the electrode and press mechanism, the system enables measurements on a single sample across multiple consecutive press conditions, reducing material usage and increasing the number of experimental trials.

Notes:

*1:An enclosed chamber that isolates experimental environments from external conditions, equipped with built-in gloves for safe manual operation inside.

*2:Bulk density: The mass of a powder divided by its total volume, including void spaces between particles, used as an indicator in powder compression forming.

*3:Ionic conductivity: A measure of how easily ions move through a material, with higher values indicating better current flow.