ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Imec Achieves Breakthrough in Single-Print High NA EUV

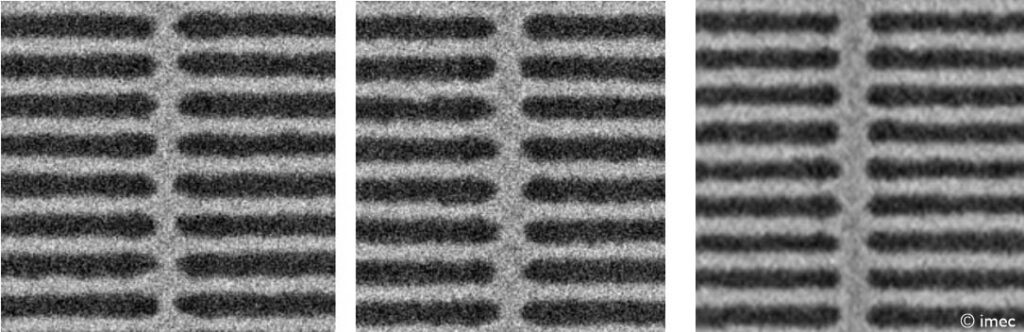

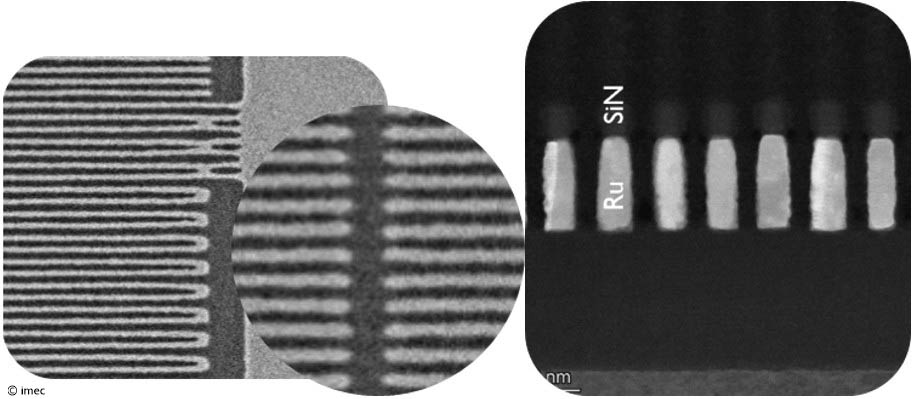

Belgian research lab imec has reported achieving new milestones in single patterning High NA EUV lithography. Specifically, imec showed single-patterned structures at 20nm pitch and 13nm tip-to-tip dimensions relevant for damascene metallization.

Imec presented this breakthrough at the recent 2025 SPIE Photomask Technology + EUV Lithography Conference in Monterey, California. At the same time, the Belgian R&D center also presented breakthrough in electrical test results of Ru lines at 20nm pitch obtained with a direct metal etch (DME) process.

The results mark a milestone in the single patterning capabilities of High NA EUV lithography for future metallization schemes, in support of advanced logic use cases.

To Pave Way for 2nm Logic Roadmap

Specifically, the breakthrough results imec announced underscore the pivotal role of the imec-ASLM partnership driving the High NA EUV transition to high volume manufacturing. Thus, unlocking the sub-2nm logic technology roadmap.

Steven Scheer, Senior Vice President Compute System Scaling at imec, said achieving these logic designs with single print High NA EUV lithography reduces processing steps compared with multi-patterning. For that reason, lowering fabrication costs and environmental impact, and improving yield.

These milestones, Scheer added, play a critical role in realizing goals for sub-2nm logic technology nodes. “In close collaboration with the imec-ASML High NA EUV ecosystem, which includes leading chip manufacturers, equipment, material and resist suppliers, mask companies, and metrology experts, we continue to jointly optimize High NA EUV lithography and patterning in support of the logic and memory roadmaps,” said Scheer.

Only in February 2025, imec demonstrated for the first time the 20nm metallized line structure. Now, the Belgian research group achieves 20nm pitch line structures with 13nm tip-to-tip critical dimension with a single-exposure High NA EUV lithography step.

For the 13nm T2T structures, a local CD uniformity (LCDU) as low as 3nm was measured, marking an industry milestone. The results were obtained with a metal oxide resist (MOR), which was co-optimized with underlayer, illumination pupil shape and mask selection.

23 September 2025