ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

UVJP to Scale Manufacturing Tech to New Heights

The Organic Vapor Jet Printing (OVJP) technology of Universal Display Corporation (UDC) has demonstrated enormous potential as the complete deposition solution for OLED TV manufacturers. The promise of the technology will however not stop with dry-printing OLED displays.

For that reason, UDC has established Universal Vapor Jet Corporation (UVJC) and has tapped the expertise of Chandran Nair to head the Singapore-headquartered company as its chief executive officer and bring the innovative thin-film printing process, now known as Universal Vapor Jet Printing (UVJP) technology, to a wide range of applications beyond OLED displays.

Bringing Thin-Film Printing to New Heights

The mission of UVJC under Nair’s helm is to bring the potential of UVJP technology across electronics and semiconductors, pharmaceuticals, and to various other fields.

“The mandate of UVJC is to globalize and scale the platform into multiple industries. Our mandate is to take this solvent-free, high-precision printing technology from lab to fab, or from R&D to industrial reality,” Nair told in an interview with AEI.

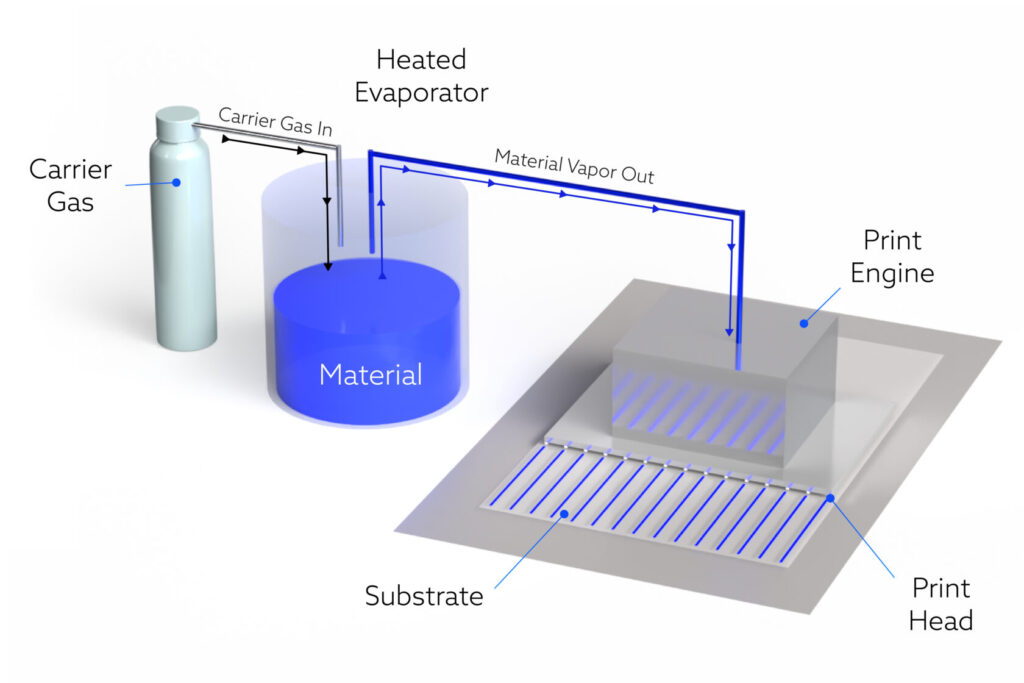

UVJP works by depositing small-molecule organic and metal-organic materials, using a gas stream, to transport the materials onto substrates.

Compared with conventional processes, what makes this technology an innovative approach is how it can use myriads of evaporable organic and organo-metallic materials. These materials are evaporated into a gas stream, and the resulting vapor is transported to the print engine, which is comprised of micro-machined jet array. This jet array design, in combination with process controls, result in patterned printing of the evaporated materials on the substrate.

Moreover, because the UVJP technology does not use the costly and complex fine metal masks (FMMs) and solvents, the process ends up cleaner than conventional systems and is also cost efficient because it uses less materials and reduces process steps.

In this interview with AEI, Nair discusses how the UVJP technology, with the first proof of concept coming next year, will revolutionize thin-film printing and deposition process beyond OLED displays.

AEI: As the CEO of a company with a very promising technology, what will be your priorities for the next three years?

Nair: Over the next three years, the main goals are to utilize different materials, fine-tune the deposition technique – the pattern deposition technique that do not use solvents – in a few more different areas, and help that go from lab to fab.

In displays, semiconductors, and electronics, we are quite far ahead already. We are also working on some pharmaceutical programs; first in their labs, and then over the next two to three years, taking them into production with fully functional production lines with some of customers and partners.

AEI: What makes UVJP the better alternative than the other conventional technologies?

Nair: There is no one-to-one comparison. But when you look at conventional methods, they often coat the entire areas and then parts of it are etched or stripped away. When you use the UVJP, the process is cleaner and more precise. You use less materials and there is a very high likelihood that you would also reduce the amount of processes. This means direct cost savings not only on the material side but also on the overall operating expense side of the process. In UVJP, you get the pattern that you want from scratch – there’s no masks, there is no waste. Moreover, it is also more precise and you get to fine lines up to 20 to 50 microns or even broader fore wider patterns if needed.

One of the most important differentiators is therefore sustainability: the ability to have a very clean process aligns with what we really need of sustainable manufacturing processes.

AEI: Do you see this technology reaching any further markets and applications, aside from displays, pharmaceuticals, and electronics and semiconductors?

Nair: In the short term, we see a lot of potentials in the semiconductor, electronics and pharmaceuticals. We also see UVJP in clean energy, such as certain processes to make batteries.

There are research groups, in universities, that are also exploring the potential impact of UVJP on molecular biology but that is still much farther away.

AEI: What are some of the challenges that you see in the implementation of the UVJC technology?

Nair: We are still in the early phase, in the stage of R&D and it’s really too early to speak about challenges scaling up as we move from lab to industrial platform. At the moment, I wouldn’t see any obstacles that we cannot surpass. I am very positive and very passionate about this technology and taking this to the market.

AEI: Can you discuss commercial efforts for the UVJP technology? Are you looking at any particular timeline?

Nair: The first proof of concepts will go live by the middle of next year, at the customer site, for their first lab implementations. Then, as our customers understand the process, we fine tune the process and the designs. Then, we are going to start integrating the processes into their manufacturing line. I am looking for lab success in the one- to -two-year time frame, and larger scale success in a three- to four-year time frame.

AEI: With the advent of AI, do you see any drastic changes in the UVJP technology on how it will be utilized?

Nair: AI is very inherently part of UDC and UVJC. UDC not only has a strong computational chemistry group, it also has an AI group that looks on ways how to use AI and help improve the efficiencies in discovering new molecules.

UVJC is looking at AI in a few different ways. First, we look at AI as we develop our technology for different applications, to speed up the design process. Secondly, as we design our tools, we use AI with predictive maintenance capabilities. We will be introducing those modules into our machines as it goes into manufacturing. We see AI playing a very important role. We are already integrating AI from scratch, it has been part of our design thinking.

25 September 2025