ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Machine Trust Takes Spotlight in New Alliance

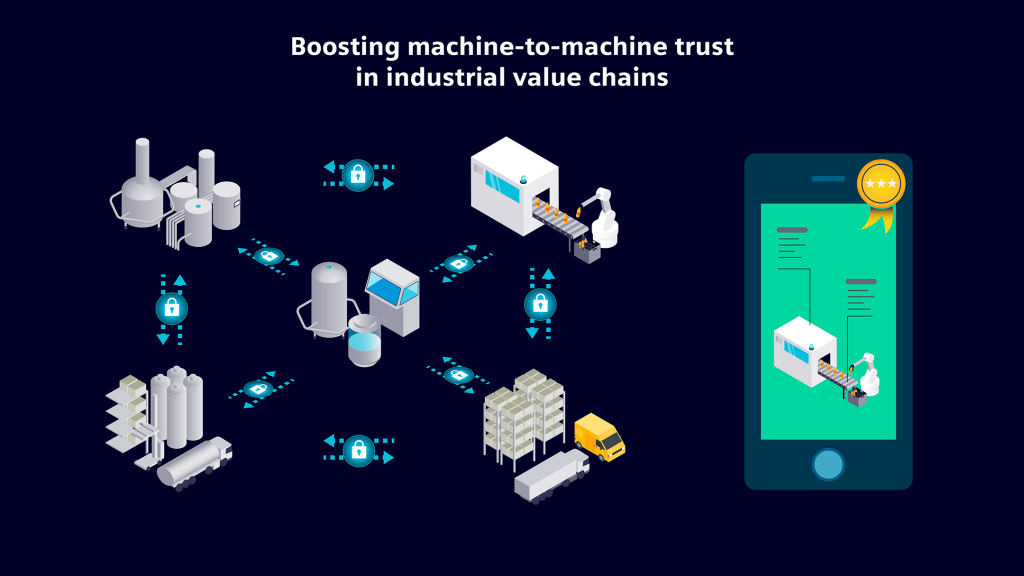

Merck and Siemens will implement solutions that will ensure machine trust in machine-to-machine (M2M) connected industrial value chains. Because of this, industrial customers can get help comply stricter regulations in value chains ranging from food, pharmaceuticals, electronics, automotive industries, among others.

Laura Matz, Chief Science and Technology Officer of Merck said, “Our collaboration with Siemens has clear potential to disrupt quality control and assurance operations across all kinds of industries.”

“Enabled by an unprecedented level of digital trust, certified M2M cyber-physical communication will not only boost quality, transparency and traceability of products along value chains but will also enable new business models.”

Cedrik Neike, Managing Board Member of Siemens AG and CEO of Digital Industries, cited the need for value chains and product lifecycles to become more transparent and sustainable. “That is why together with Merck we will develop a completely new digital solution that enables ‘trustworthy’ communication between machines, for example, for the exchange of production data and laboratory data.”

IIoT Role in Machine Trust

Due to the increasing complexity of value chains, the current traceability, transparency, and quality control requirements are growing exponentially. As such, industrial internet of things (IIoT) is rapidly transforming manufacturing across industries and calls for an effective and secure data and information exchange.

Nevertheless, within the current IIoT context, there is a lack of M2M communication regarding the quality status of many products. Consequently, the solution aims to provide a framework for an efficient M2M interaction.

The targeted solution would provide all parties involved in the value chain with an immediate single-source-of-truth access point to trusted data and enable new levels of traceability, transparency, safety, and quality of industrial products. Because of this, customers can generate disruptive business models contributed by machines in the IIoT sphere.

Cutting-edge technologies such as smart contracts, tokens, blockchain, and industrial edge computing can anchor physical objects to a digital identity and thus ensure transparency and authenticity of information and physical objects. This promotes originality and helps prevent the creation of counterfeit products.

Scalable Across Value Chain

Nonetheless, Merck and Siemens aim an end-to-end solution that will enable customers rely on one immutable single source of truth between production and laboratory quality control. Moreover, Siemens eyes an object centric IIoT data ecosystem where objects can communicate by sharing data within a trusted environment. Then, companies also plan to combine the crypto anchor technology portfolio of Merck with Siemens’ trusted traceability system to make them interoperable based on blockchain technology.

Clearly, the companies plan the solution to be scalable across the entire value chain. This is because stakeholders are to have access to all data across the entire lifecycle of a product, from product design to use by the end consumer. This would simplify processes and significantly increase efficiency across industries.