ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mobile Service Carriers Stake Out Smart Factory System As New Revenue Source

Korea’s three mobile service carriers – SK Telecom, KT and LG U+- are staking out smart factory market as a next generation of revenue sources.

Korea’s smart factory market has been booming in recent years, as an increasing number of factories across the country are rapidly rebuilding their operations around Industry 4.0-based smart factory platform not only to save costs, but also improve efficiency and productivity.

Further fueling the boom is ironically the outbreak of COVID-19 pandemic that has been still prompting companies to speed up their adoption of smart factory platform to keep their operations safe, resilient, and immune from unexpected events like epidemics and accidents

With low data latency, ultra-high speed data transmission, and massive accommodation of edge devices, 5G mobile communication technology is a key technology enabler for the smart factory system.

According to market research firm “market & market”, Korea’s smart factory market will almost double from 8.9 trillion won in 2020 to 17 trillion won in 2024. some sources

The country’s mobile service carriers bet on the huge potential.

LG U+, the country’s third largest mobile service carrier, seems to be the most aggressive.

To make up for relative woes in mobile service market, LG has recently reoriented its 12 smart factory solutions under a new brand name of “U+ Smart Factory”. These solutions are all offered in a custom-made format, including Big Data Analytics-based motor and switchgear diagnosis, AI-centric intelligent video security system, and real-time detection system of hazardous materials.

For example, LG’s smart factory solutions can allow factory operators to remotely control delivery robots to bring back and forth parts and components across assembly lines, and monitor all production processes, equipment, and utilities around-the-clock to diagnose them in real-time.

But, its AI-based intelligent video security solution also monitors, detects, and automatically alerts of incoming dangers whenever there are smokes, flames, and security breach. The video system even can detect whether or not factory floor workers wear a safety helmet.

U+ Smart Factory: IoT Hub for Smart Factories

Coming built with various sensors, its detection system of hazardous materials can monitor and detect airborne hazardous materials like toxic gases, but also even predict where atmospheric pollutants out of factories are heading for.

LG U+ has been supplying these system and solutions for 100 companies across the nation, including its captive market like parent LG Holdings’ subsidiaries or affiliates.

Cases in point are affiliate LG Chem’s Yeosu chemical plant, which is located at Yeosu City, southern port city of Korean peninsula, and affiliate LG Electronics’ “Smart Park” factory in Changwon City.

The Yeosu petrochemical plant built a atmospheric environment diagnosis system around LG U+’s detection solution for hazardous materials, allowing the system to monitor in real time and predict the direction of airborne pollutants.

LG’s “Smart Park” factory deployed an army of 5G-based logistics robots around LG U+’s 5G smart factory hub system to allow them to carry raw materials as well as parts and components around factory floors and assembly lines.

Metatron Grandview – Cloud-based Smart Factory Monitoring

The customer list goes so long as to include hospitals and other petrochemical plants, including BASF Korea’s Ulsan petrochemical plant.

For example, the BASF Ulsan plant had built a location-based real-time workforce monitoring system around LG U+’s 5G solution.

LG U+ aims to grab 50% of Korean smart factory market by 2025. kret

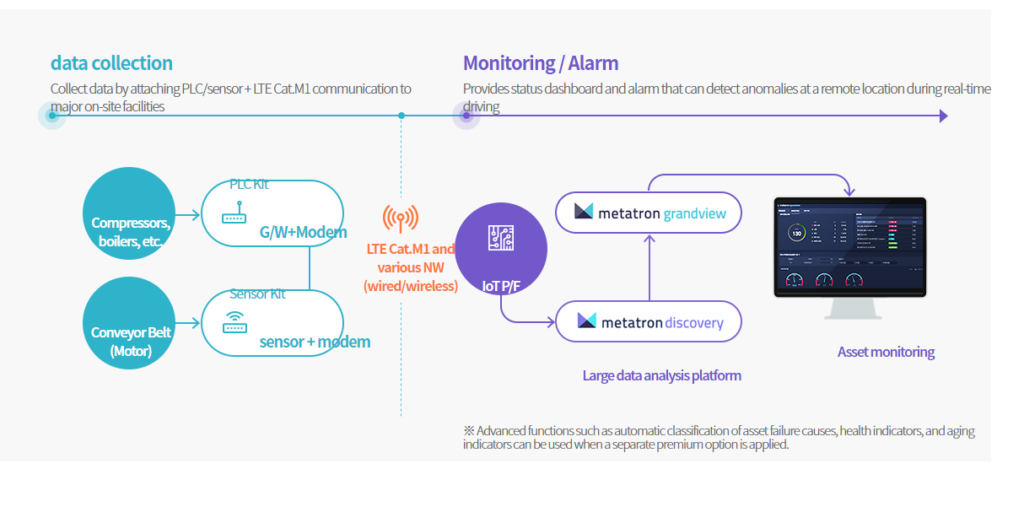

The country’s largest mobile service carrier SK Telecom is enthusiastic, too. SK Telecom has recently unveiled its own indigenous smart factory service called as “Metatron Grandview, a subscription-based factory monitoring and diagnosis system.

Coming built with a wealth of sensor system, the sort of industrial IoT hub monitors and diagnoses various equipment and utilities in real-time and then predicts and schedules maintenance and repair timing on a monthly subscription basis.

The hub system is a cloud-based predictive maintenance solution that can remotely monitor the operation of major equipment and factory assets as well as utility systems for small-and medium-sized factories. It can detect abnormalities with parameter values like flow, torque, temperature collected in real-time and sound alarms whenever something goes wrong.