ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Panasonic Pursues Autonomous Factory in Electronic Components Mounting

The environment surrounding the manufacturing industry is changing more drastically than ever before. In addition to the progress in digitization, diversification of customer needs, borderless business, and global environmental protection, the industry has to respond to unpredictable natural disasters and pandemics that have never been experienced before. In such a drastically changing environment, it has to satisfy quality, cost, delivery (QCD) and correspond to the demands of customers and society, such as high-mix, low-volume production, shortened product cycles, and strict traceability management. In the past, the industry has taken a cumulative approach, such as repeating improvements based on the “experience,” “intuition,” and “guts” at the manufacturing site, and introduce new equipment to improve. In the present phase, however, such approaches have become hardly sufficient.

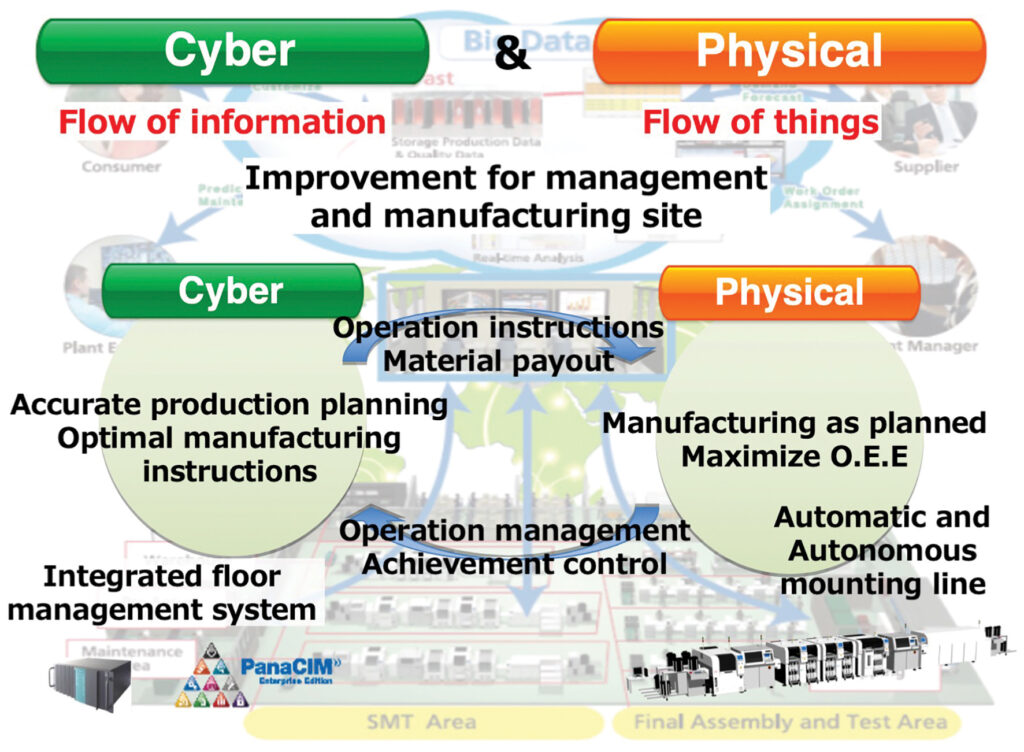

Panasonic has followed the idea of making factories smarter. The company calls it the Cyber Physical System (CPS), which has been advocated recently. In the physical domain, the company has expanded the automation functions of its equipment. It has developed a system that connects those of customers with other companies’ equipment on a production line. In the cyber domain, it has enabled switching models on a line all at once and utilized the developed functions and systems to manage the inventory of the entire floor (Fig. 1). This has made it possible to formulate an optimal production plan and confirm the actual difference from the plan by collecting operation information. However, the analysis and judgment have been left to the customer’s hands. Thus, it is difficult to immediately respond to drastic changes in the environment and manufacturing sites.

From now on, it is absolutely necessary to perform digital transformation at the manufacturing site that will bring about innovation far beyond the conventional wisdom. To that end, the company is going to make more effective use of the latest technologies, such as internet of things (IoT), sensing, artificial intelligence (AI), robotics, and 5G.

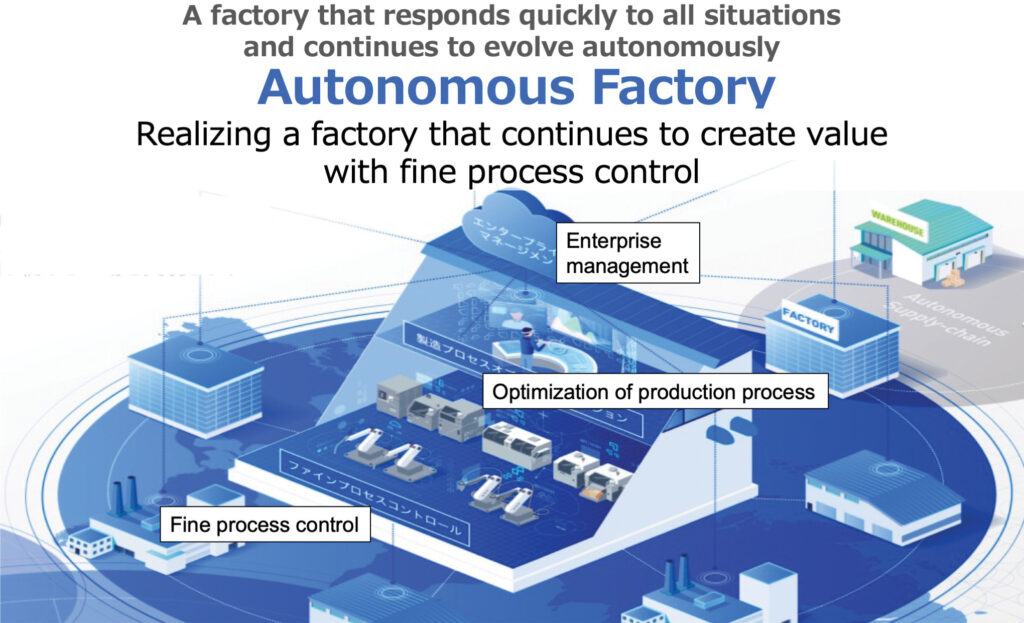

Panasonic aims to develop an “autonomous factory”, which is a factory that responds quickly to all situations and continues to evolve autonomously.

What is Autonomous Factory?

Until now, the company has set up the “connected factory” and has realized information linkage with equipment of various manufacturers and with systems of customers. Based on this achievement, the new “autonomous factory” aims to realize a factory that can continue to provide value to customers both at the manufacturing site and for the management. To this end, productivity is maximized through optimal control of each edge device and through linked information between the “physical” area and the “cyber” area. In this way, the “autonomous factory” controls variations in on-site resources such as people, equipment, and materials, as well as minimizes investment.

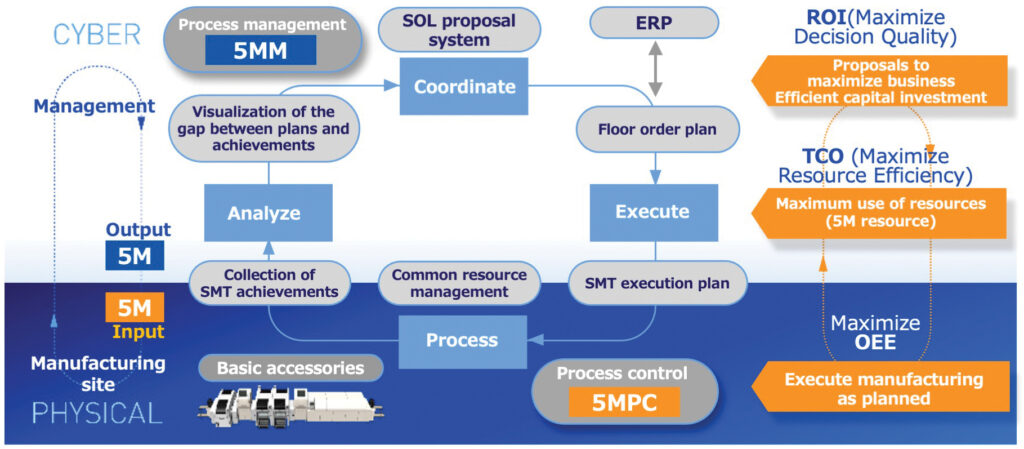

In this article, the field of electronic components mounting will be classified into three layers. First, the goals to be reached and problems to be solved will be summarized for each layer. Then, it will describe how an autonomous factory is realized. The three layers consist of the management layer, floor-management layer, and manufacturing-site layer (Fig. 2). The management layer makes the decisions on investment in new equipment and those on large orders for the purpose of achieving management goals. The floor-management layer controls the production plan of the entire factory and maximizes the production efficiency. The manufacturing-site layer completes daily production without delay.

Management layer

Achievement goals: Maximize return on investment (ROI)

Problems to be solved: The number of equipment currently owned is known. However, the knowledge on the actual availability factor and resources for additional orders is uncertain. It is difficult to make effective investment and aggressive order planning. Thus, the production capacity of the factory cannot be maximized.

Floor management layer

Achievement goals: Reduction of total cost of ownership (TCO)

Problems to be solved: It is necessary to keep a margin in the production plan in case of an unexpected stop of production (moment stop) of equipment or line. Moreover, because these stops occur suddenly, the time of occurrence and the stop time cannot be accurately estimated. Therefore, the time margin longer than actually necessary must be secured and the resources invested on the floor cannot be fully utilized.

Manufacturing-site layer

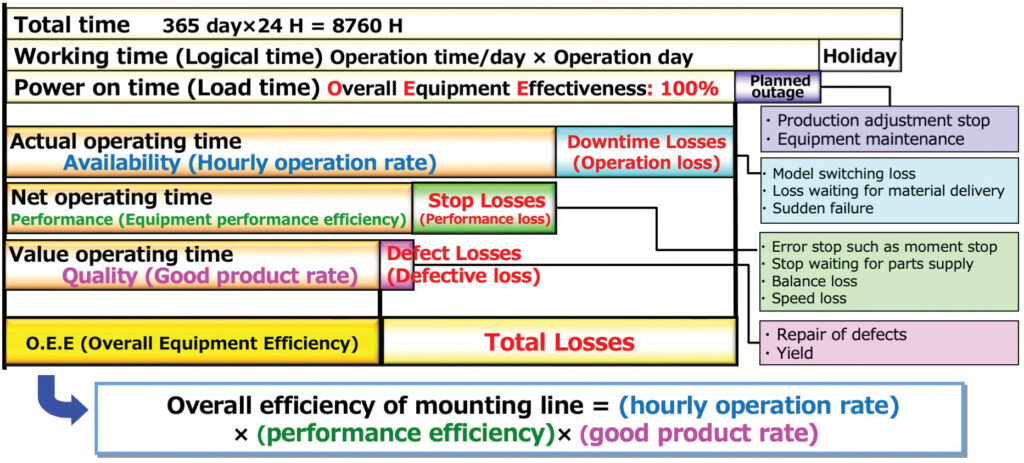

Achievement goals: Maximize overall equipment effectiveness (OEE)

Problems to be solved: Even if equipment troubles or sudden plan changes occur, the delivery date will not change. This would require long hours of work for the purpose of meeting the deadline.

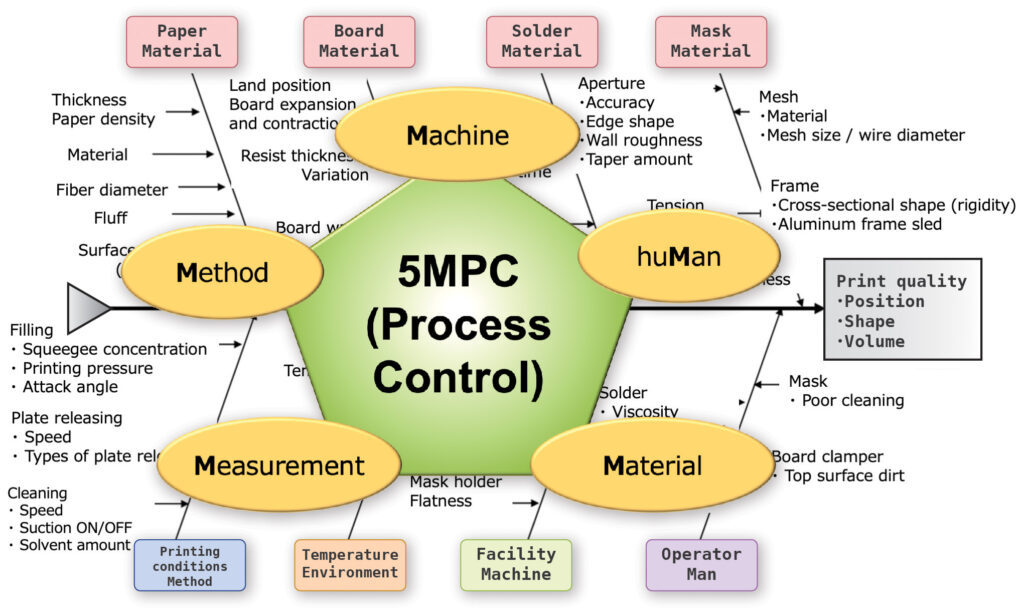

These problems are attributed to the variation of 5M (huMan, Machine, Material, Method, and Measurement) that affects the quality at the manufacturing site in every layer. Because the variation of the 5M cannot be visualized, the manager would have difficulty in determining the actual situation. Because the 5M varies, the manufacturing site would be busy in making necessary adjustment every day. Therefore, the autonomous factory should acquire the 5M information and connect “cyber” and “physical” with the 5M information to realize the management of the entire factory.

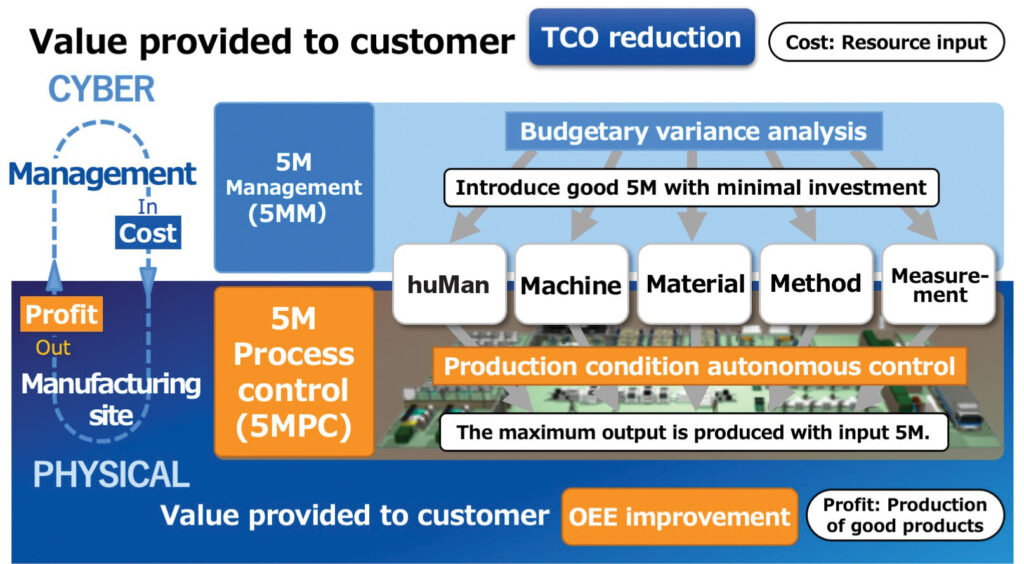

The 5M in the “cyber” area is assigned as 5MM (5M Management) and the 5M in the “physical” area is assigned as 5MPC (5M Process Control). The 5MM autonomously formulates the optimum production plan and maintenance plan according to the current floor conditions. It maximizes ROI and reduces TCO by suppressing differences between production plans and actual results. In the 5MPC, the production conditions of the equipment itself are autonomously changed in response to daily changes in materials and production conditions. This change suppresses quality variations and maximizes overall equipment efficiency (OEE) (Fig. 3). This is the fine process control of the company. Details on the 5MM and 5MPC will be explained below.

What is 5MM?

The 5MM concept aims to reduce TCO by optimally allocating resources and utilizing them according to the actual operating conditions. For that purpose, it is important to minimize the difference between the production plan and the actual results, and to maintain the quality of the 5M to be put into the field. This is achieved with the following functions in the 5MM (Fig. 3).

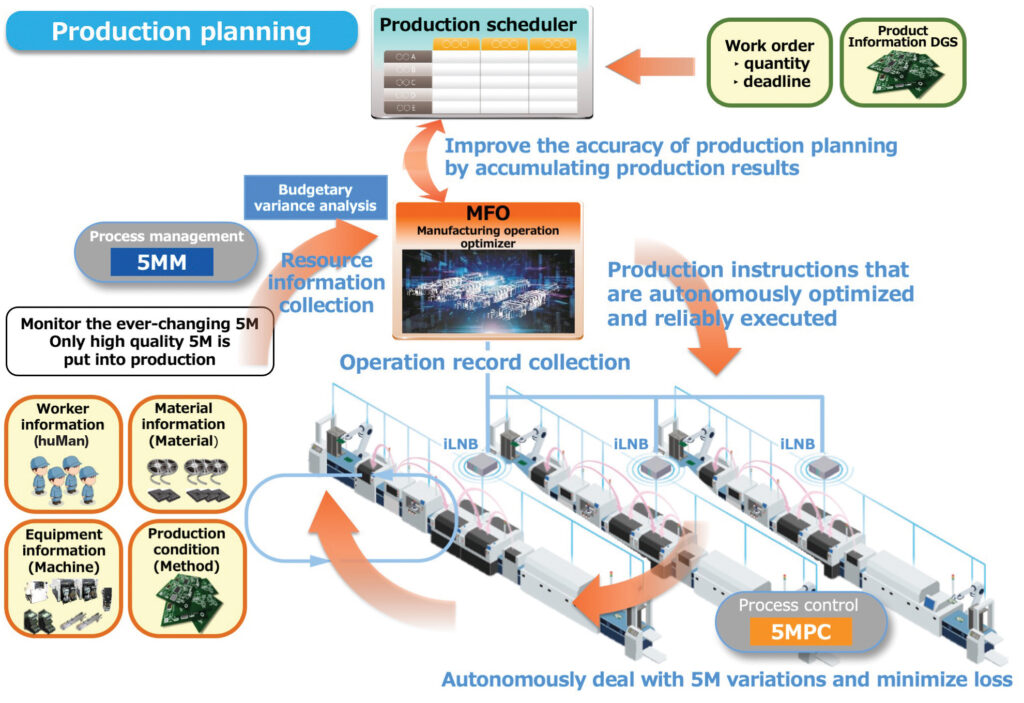

1) Making an accurate production plan based on the condition of the entire factory

As mentioned earlier, the company has already established the mechanism for transmitting information between facilities and systems, including the material management for the entire factory. At present, however, the specific production plan and production order are manually decided by a floor manager. As a system to support this, the company provides the manufacturing operations optimizer (MFO) that enables simulation of the entire floor. By using MFO, it is possible to perform simulation for an accurate production plan.

In the 5MM, this will be further developed into a system that can formulate the production plan itself based on the information on materials on the entire floor and on the information on the operation of the production line. In planning, the operating rate of the line as well as the supply from the material warehouse and the common mounting components are taken into account for considering the flow line of the entire floor. In addition, the accuracy of the simulation will be improved by analyzing the accurate operation results from the site and comparing and analyzing the differences between the plans and the results. By autonomously considering the results for planning, each factory can be optimized (Fig. 4).

2) Keep sensing equipment in optimal condition, predictive maintenance

At present, there is no way to determine the deterioration of the equipment condition, and regular maintenance is being carried out with a wide margin. This is one of the factors that reduce the equipment operating time.

In the future, more sensors will be added while utilizing the functions of existing equipment to visualize the condition of the equipment itself. This will lead to optimization of the maintenance cycle. In addition, the maintenance cycle is extended by comparing the current status with the ideal status and autonomously taking actions and repairing when a certain difference occurs. In the following, examples, in which these existing functions are utilized, will be introduced.

a) Monitoring of axis operating distance

The equipment has many rotation axes, which are driven by motors, and with different amount of operation of each axis is different. Presently, the maintenance is required every month (greasing, etc.) or every three months, and there is only a rough guideline for each operating axis. This maintenance period is different from the required maintenance frequency corresponding

to the actual amount of operations. Therefore, by monitoring the operation of each axis and actually measuring and calculating the operation distance, it is possible to determine the optimum maintenance interval that matches the actual operating rate of the equipment. In this way, both excessive maintenance and operation without maintenance can be suppressed.

b) Monitoring of board transfer time

When transporting equipment and boards in the facility and between the pre-process and the post-process, a transport motor is operated at a constant speed and is controlled by the transport belt. At present, there is a function to stop the equipment as a transport error when boards have not been transported for a certain period of time (when a sensor detects the absence of a board). This operation is necessary only when abnormal behavior occurs. Because the equipment itself knows the transfer speed and the board size, it can calculate the expected transfer time for each board size. Therefore, by comparing the actual transport time with the expected transport time, the detection of a phenomenon becomes possible. The phenomenon involves slips of the board due to decrease in the frictional force between the board and the belt, which in turn is caused by belt wear and foreign matter adhesion. Cleaning or replacement can be performed prior to the occurrence of the abnormal behavior such as transport errors.

With these functions, the 5MM will provide the floor-management layer with a factory that can produce as planned and maximize the production capacity. It will assist management decisions (to maximize ROI) by presenting, in an easy-to-understand manner, the factors that determine whether the management needs to make capital investment or whether additional production is possible. In addition, it will support the realization of 5MPC functions by introducing high-quality 5M to the manufacturing site.

What is 5MPC?

The 5MM concept proposes a production plan that minimizes investment, considering the actual status of the entire factory and the condition of the equipment. The execution of the plan requires the suppression of operational loss, performance loss, and defective loss, that is, maximizing and maintaining OEE (Fig. 5). This requires not only the evolution of basic performance of equipment but also that the equipment continues to have the same performance. The 5MPC of the company is to monitor the state of 5M used in the production in real time and to perform “fine process control of 5M” responding to changes autonomously and quickly (Fig. 3).

For the purpose of maintaining the quality of the mounting line, it is important to ensure the quality in the printing process. A major premise for improving OEE is to kill products with poor print quality. Factors that affect print quality include materials, such as masks and solder, equipment, printing conditions, manual work, etc. The 5MPC monitors the state of the 5M and (immediately and autonomously) performs a fine control (Fig. 6). In the following, as an example of applications of the 5MPC, the development process of the company’s screen printing machine SPG2 (Fig. 7) will be introduced.

1) Maintaining the first-pass rate of inspection machines

For the purpose of maintaining print quality, it is important to maintain a high level of the first-pass rate of the solder paste inspection (SPI) machine. The first-pass rate is the ratio of non-defective products that can be sent to the next process without an operator’s check. Therefore, the functions taking the following actions according to variations of the 5M are being developed.

a) Position correction is performed using the conventional Advanced Process Control Feed Back (APC-F.B.). In addition, the print quality information is fed back from the SPI. Then, the production conditions such as squeegee speed, printing pressure, plate release, cleaning, etc., are automatically adjusted in such a way that the variations of the print quality (solder volume fraction, etc.) are put back to within the normal range. (APC-F.B. is a function that feeds back the solder printing position based on the inspection result in cooperation with the inspection machine.)

b) The quality is maintained by sensing the state of printing materials, usually subject to lot differences and changes over time, by restoring them to the desired state, or by automatically adjusting printing conditions. Furthermore, if the situation cannot be dealt with by automatic adjustment, the operator or higher-level system is notified of the necessity of replacement of the material.

c) Conventionally, the adjustment of printing conditions has been performed with the knowledge and intuition of an operator. In particular, the initial conditions vary greatly depending on the operator, causing quality fluctuations. For the purpose of suppressing variations due to human skills, the system is equipped with the function of automatically setting initial conditions in cooperation with SPI. Therefore, the quality stability is ensured from the initial stage of production.

OEE is further improved because the print quality is guaranteed and the mounting difficulty is lowered by the above-mentioned functions. In addition, the frequency of moment stops, which randomly occur in the inspection machine, is reduced, contributing to the stabilization of the total throughput of the line and the floor.

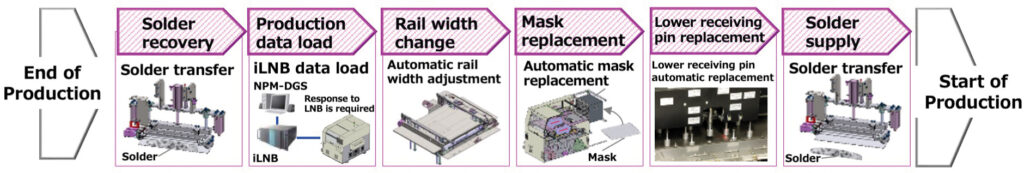

2) Automatic model switching and material replenishment, making human intervention unnecessary

Depending on the level of operator’s skill, the time required for switching various materials at the time of change in produced models and the quality of supplied materials like solder often fluctuate. In addition, because the timing of material supply also depends on the intuition and judgment of the operator, there appears a loss time of waiting for material supply. In the future, by automating and integrating material preparation, transfer, replenishment, and switching with automated guided vehicles (AGVs), variations in quality, work time, and waiting time will be suppressed.

In the company’s printing machines, data switching, solder recovery, mask replacement, automatic replacement of lower receiving pins, and solder reloading and supply have already been automated. They have realized the model switching function without human intervention. In particular, as an important point to suppress the variation in switching time, they can stock 10 masks in the equipment, leading to the vanishing waiting time for the mask supply, which is likely to cause time loss. In addition, the solder transfer device can recover and resupply solder from the mask without destroying the shape of the solder. “Trial-run printing” before the start of production is not necessary. No human intervention is required and the switching time can be significantly reduced (Fig. 8).

In material supply, waiting-time loss and variations are eliminated by transporting and supplying solder pots and masks by AGV. These can be exchanged during the production operation of the equipment without stopping the production. In addition, the AGV movement route and supply timing are controlled by the integrated system in such a way that the route design and timing do not interfere with the movement of the AGV for other purposes such as for mounting machines. Further, for paper replacement, the paper re-screening nozzle makes it possible to eliminate the need for the material supply itself.

With these 5MPC functions, it is possible to autonomously and quickly respond to changes in the state of the 5M used in production. Because the OEE is maintained at a high level and the throughput of the production line is stable, the production plan proposed by the 5MM becomes realizable. In this article, the 5MPC has been introduced using the printing machines as an example. All products developed by the company are based on the same development concept. Mainly utilizing real-time sensing and real-time control, the company will continue to provide solutions to each of the three layers of the management, the floor-management, and the manufacturing-site.

Conclusion

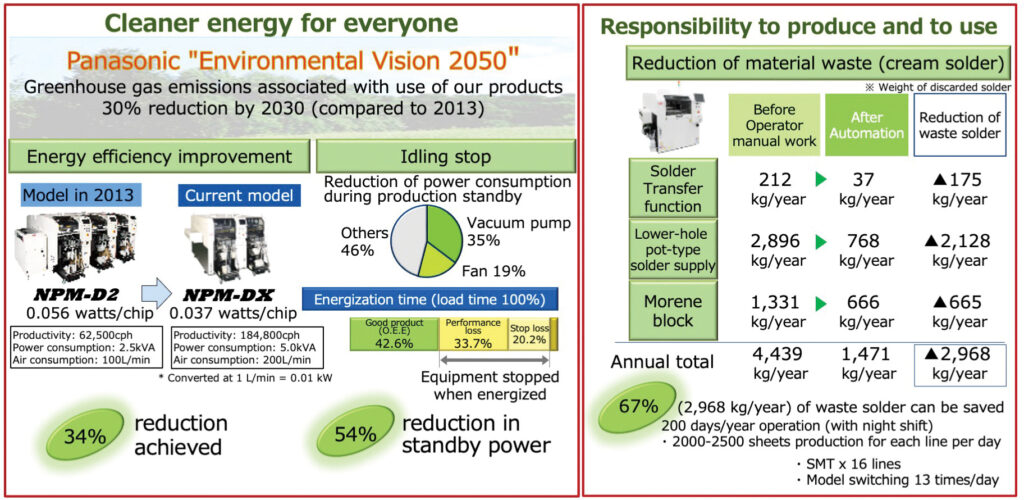

In recent years, there has been an increasing demand for supporting the environment as a global social problem. The company has been developing solutions that contribute to sustainable factory operations by taking environmental measures such as reducing power consumption and waste solder. Aiming to “reduce greenhouse gas emissions by 30 percent by 2030 (compared to FY2013)” set forth in the company’s “Environmental Vision 2050”, it has already reduced power consumption per chip by 34 percent for mounting machines and reduced standby power consumption by 54 percent by idling stop. In the printing machine, the amount of waste solder is reduced by 2,968kg/year by automating the work of handling solder (solder transfer, solder supply) and reducing the amount of side-leakage of solder from the squeegee

(Fig. 9).

As mentioned above, the company will play the role of a partner who solves the manufacturing problems faced by customers and optimizes the manufacturing process, optimally combines the knowledge, know-how, and technology of the people who work in the field, and realize, together with customers, the “autonomous factory” (Fig. 10), which responds quickly to all situations and continues to evolve autonomously.

About This Article:

Panasonic Corporation provided the contents of the article.