ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

OMRON Launches New i-BELT Data Management Platform

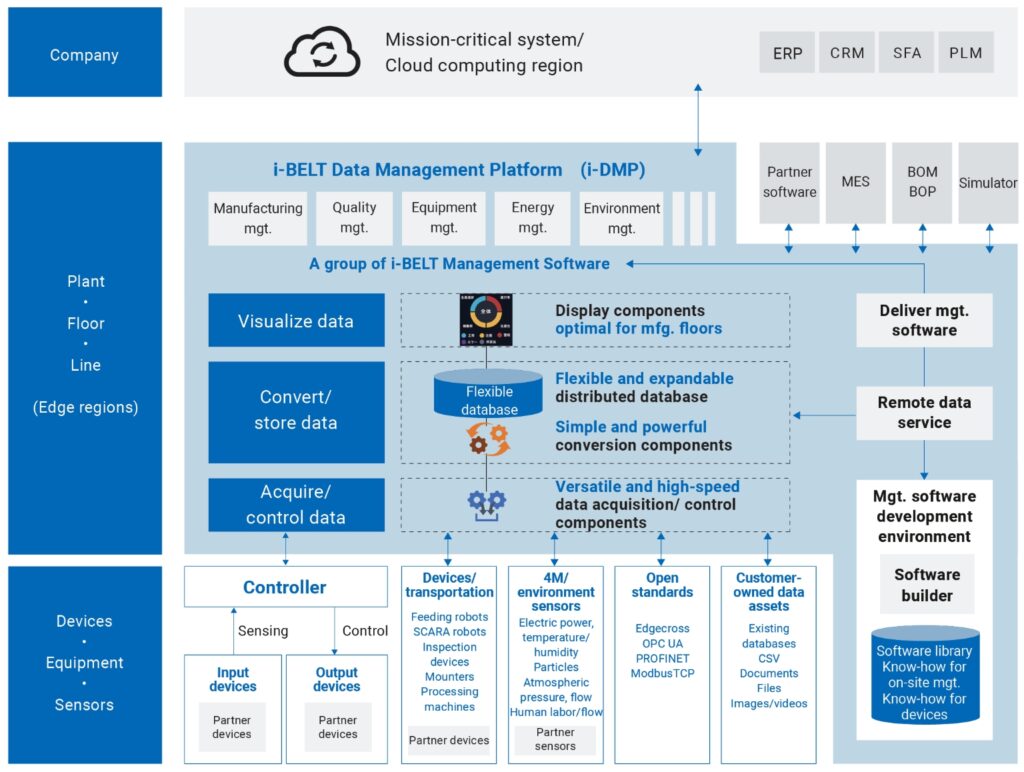

OMRON Corporation has developed the i-BELT Data Management Platform (i-DMP)*1, which will be embedded with the i-BELT*2 manufacturing site data utilization. This new data-driven service streamlines the integrated management of diverse data, which has never been utilized before, to bring about improvement on manufacturing floors. As a result, this platform can assist customers in tackling their issues both effectively and efficiently.

Handling Data Utilization

In recent years, high-speed networks and other advanced information technologies have been introduced to manufacturing sites, making it possible to store and analyze a variety of field data. This in turn has turned greater attention to shop-floor initiatives that utilize such data to make positive differences in productivity and product quality.

Taking a closer look at the realities on the manufacturing floor, however, there are not a few instances where efforts have been made to take advantage of various software and devices that support data utilization, with no tangible results. This can also be seen in the push to attain carbon neutrality, one of the prime imperatives for manufacturing businesses. For example, many say, “We’ve visualized the energy data, but we don’t know where to start to seek solutions. We also find it difficult to connect data-gathering software and devices to existing systems.”

Adoption of i-DMP

To tackle these challenges, OMRON began offering the i-BELT on-site data utilization service in 2017. And now, this innovative service has been updated to better focus on issues unique to each manufacturer.

The i-DMP provides manufacturers with quicker access to the i-BELT service and makes it possible for them to continuously advance solutions to their issues. With the i-DMP, for instance, they can integrate energy data and productivity data to produce an indicator for energy productivity, which may be used to drive initiatives to achieve carbon neutrality. Having been introduced to several of OMRON’s plants, the i-DMP has demonstrated its merits.

At OMRON Kyoto Taiyo Co., Ltd., they use a system modified to best cater to the specific needs of a welfare factory that employs persons with disabilities. In response to the growing focus on diversity in corporate management, they use the system to constantly gather data on manual labor, as well as equipment data, with which to monitor the status of each worker in real time. As a result, they successfully increased productivity by 11%.

Another benefit of the i-DMP is the time it takes to build a system, which is one-eighth*3 of its predecessor. Currently, the i-DMP is typically offered as an add-on to the i-BELT service, but OMRON plans to provide its partner businesses with the i-DMP under a license agreement.

Features of the i-BELT Data Management Platform

1. Utilizing data by making the most of existing on-site systems

Easily connected to diverse networks, relational database (RDB), and factory automation (FA) devices, the i-DMP gathers and stores data, as needed, which is dispersed throughout the manufacturing floor, such as those from existing systems and programmable logic controllers (PLCs), in the edge region in real time for uniform data management. Without using cloud computing or other services, the i-DMP can be started on a small scale for data utilization at manufacturing sites. The ease with which it can be expanded allows users to enhance functions in stages, according to self-set goals or evolution scenarios for their manufacturing needs.

In terms of connectability, i-DMP features OPC-UA, Ethernet/IP, PROFINET, Edgecross*4, etc, as communication protocols; PostgreSQL, Oracle Database, Microsoft SQL Server, etc as RDB; and a diverse range of FA devices, including code readers, industrial cameras, and particle sensors as control devices.

2. With management software, visualizing manufacturing floors in real time to locate latent problems

i-DMP can be used in combination with more than 50 titles of management software and their connected components, which incorporate knowledge OMRON has garnered on-site. When that happens, the i-DMP visualizes data gathered from the edge region to monitor changes in on-site conditions in a way that addresses specific challenges at manufacturing sites (for each product/process, standard/actual human-hours, variances in human work). This swiftly puts together a data utilization system optimized for a customer’s purposes, which then brings latent issues to the surface and kick-starts necessary remedial actions. For instance, for a process that involves a high degree of human input, the system may be used to analyze data regarding a worker’s flow, action, and/or operation to come up with plans that address possible causes of problems and then create a cycle of improvement for total optimization.

3. Utilizing unified on-site data to continuously improve/advance manufacturing floors

By gathering/storing diverse data in the edge region for unified management, the i-DMP analyzes data in order to identify areas of manufacturing floors in need of automation. It also sends feedback to controllers.

To address the ever-diversifying and complicated challenges manufacturers face, the i-DMP promotes digital transformation (DX) on-site by implementing over 250 innovative applications that have been created and accumulated by OMRON’s unique value generation concept “innovative-Automation” and utilizing artificial intelligence, thus supporting manufacturing innovation.

Addressing Social Issues through Automation

In April 2022, OMRON kicked off its new long-term vision, Shaping the Future 2030—We will Continue to Create “Innovation Driven by Social Needs” Through Automation to Empower People. As social issues become increasingly multi-layered, OMRON needs to re-envision the way it creates value. For example, in addition to the more conventional way of creating value in the form of goods, it will also be combining goods and services and selecting the implementations which offer the highest value.

The i-BELT manufacturing site data utilization service is one such initiative. OMRON will remain committed to further evolving the i-BELT service to visualize the ever-diversifying/complicated issues experienced on manufacturing floors and support the establishment of an improvement cycle on-site to revitalize those on the manufacturing front, thus supporting the acceleration of DX at manufacturing sites and the achievement of carbon-neutral manufacturing in our efforts to continually innovate the art of manufacturing.

*1: i-DMP (i-BELT Data Management Platform) – A data utilization platform that sorts and converts data gathered from various devices and systems into viable forms

*2: i-BELT – A joint development service that utilizes data available at manufacturing floors to solve issues.

*3: 1/8 – Calculated by OMRON from data gathered at OMRON Kyoto Taiyo Co., Ltd. (Internal evaluation results as of June 2021.)

*4: Edgecross – An open software platform in the edge computing region that achieves harmonization between FA and IT beyond boundaries of companies/industries. For details, visit the following website link. https://www.edgecross.org/ja/