ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FUJI Rises up to Automation Challenge with FSF 2.0

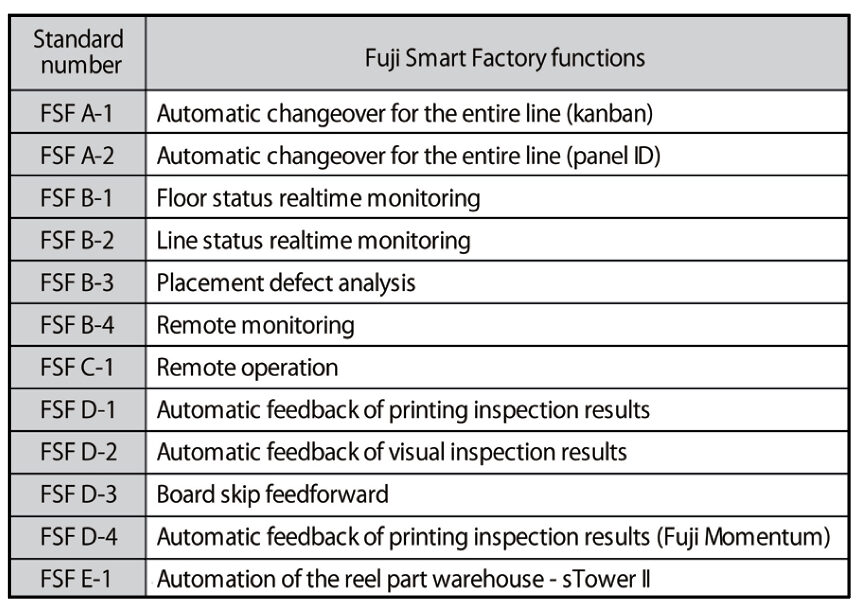

FUJI Corporation launched the FUJI Smart Factory project in 2017 (Photo 1), and since then has provided many smart factory solutions (Table 1). These solutions are designed for production lines with configurations centered on FUJI’s placement machines, mainly through machine-to-machine (M2M) coordination. To provide effective solutions to customers, FUJI has been working daily on the development together with members of FUJI Smart Factory inside and outside of Japan.

FSF 2.0 Challenge Toward Automated Production

There is a growing demand in the surface-mount technology (SMT) market to automate production processes and work at production lines and floors for the entire factory. This system is shifting beyond mere automation to labor savings and ultimately to unmanned operations. To respond quickly to these needs, FUJI has released the FSF 2.0 project (Photo 2), aiming to provide a new automated production system using NXTR as a platform.

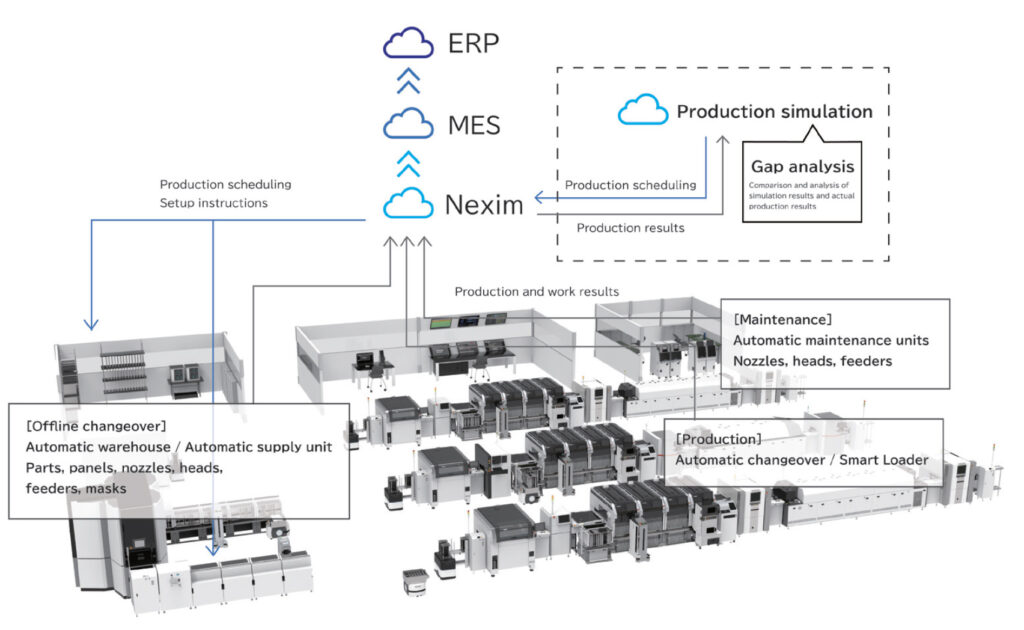

The FSF 2.0 project introduces digital twin technology to the SMT floor to achieve zero gaps between the virtual (production plan and simulation) and the real (actual production and production results) production process.

Virtual (production planning to simulation)

1. Creating production plans by the user system (model, quantity, deadline, delivery destination, etc.)

2. Creating detailed production schedules and optimizing programs using Nexim

3. Creating virtual data by simulating in advance using a production simulation tool

Real (actual production to production results)

4. Automating work before automatic production is started: Issues instructions to warehouses to check out parts, feeders, masks, and other items – distribute the checked out items using automated guided vehicles (AGVs) – prepare for changeover and supply parts at external changeover areas – distribute using AGVs and automatic supply (collect unnecessary items) – automatic changeover (programs, materials, parts), as well as issuing systematic instructions to operators during production, including work guidance, error notification, and remote control commands for the equipment in the line

5. Real-time quality and operating status analysis during production [using Intelligent Process Quality Control (IPQC)] for autonomous control

6. Monitoring, reporting, and analyzing the actual production results for the entire production line

Analyzing gaps between the virtual and the real

7. Analyzing the gaps and investigating improvements based on virtual-real comparison result reports.

Virtual Production Process

Creating and optimizing production schedules (linking with the user system)

Production orders created on the user host system are imported into Nexim, in which the production orders and part setups are optimized.

Optimization for production with automated part supply

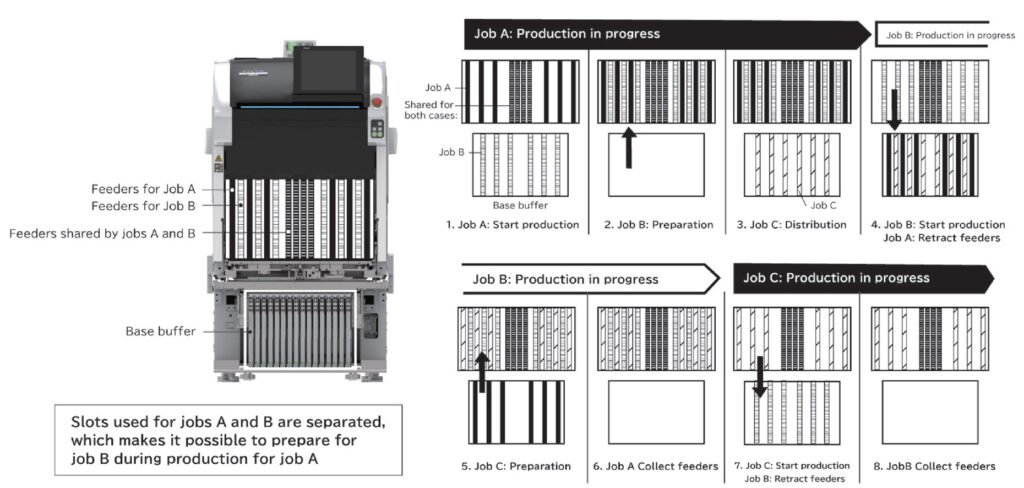

A new optimization method has been adopted for NXTR, which uses an automatic part supply system, the Smart Loader (Photo 3).

By using the Smart Loader to perform automatic feeder exchange, NXTR can allocate feeders for the current and next production to production slots (the upper level) and allocate feeders for the subsequent production to the base buffer (the lower level). NXTR provides a system that can deliver optimal high-mix, high-volume production in which the optimum cycle time can be achieved while supporting a large variety of parts types.

Checking part inventory

There are two tasks to be done before finalizing production schedules: inventory checks and part allocations. Nexim is equipped with functions for checking whether all required parts are in stock for production when creating production schedules and allocating the part reels to be used. This eliminates situations in which production cannot be performed due to a lack of parts immediately before starting production. If the parts required for production are to be used on different lines, this function can reserve the parts for this production.

Simulation

Once the detailed production plans have been finalized, total production time is calculated by simulating the entire process from checking out from the part warehouse to the unloader at the end of the production line.

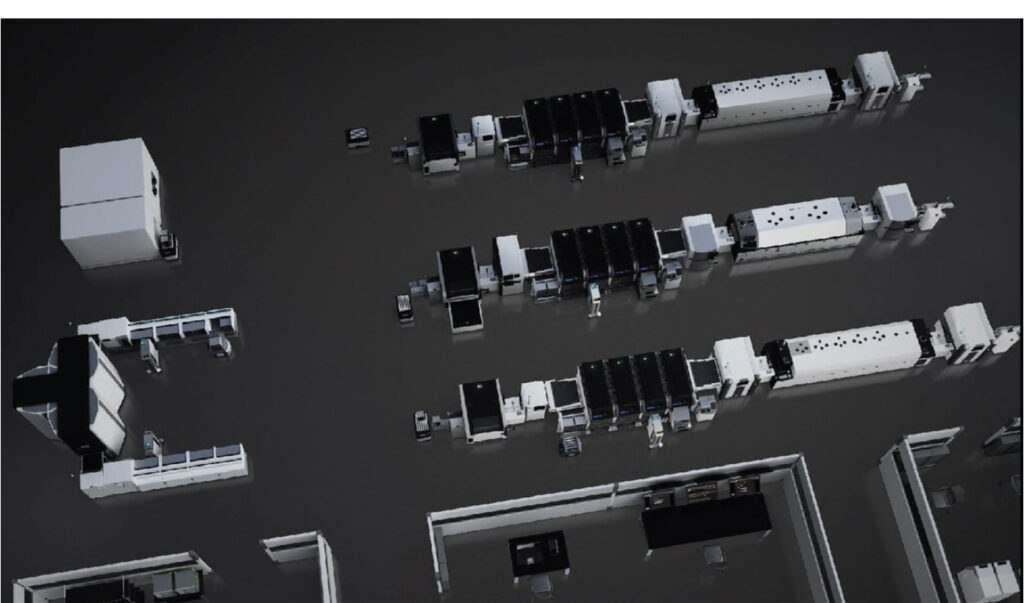

It is possible to generate highly accurate simulations by creating a model of the applicable production floor in which operation conditions and the movements of operators, objects, and equipment are registered, while also registering product specifications and production schedules created in Nexim (Photo 4).

Real Production Process

Timely instructions for checking out from automatic warehouses and external changeover based on the production schedule and progress

Nexim creates a list of materials and equipment required for production in order of usage time. By linking with warehouses, Nexim can issue guidance for automatic check out and preparation work based on production progress.

Parts and Feeders

Since NXTR uses feeder magazines that can load up to 20 feeders for transport, Nexim is designed to request automatic warehouses to check out 20 part reels at a time. This establishes a system that allows for everything to be prepared in the right place at the right time for the exact volume needed.

Fully automated supply, exchange, and collection of feeders by AGVs

The parts required for production are loaded to a feeder magazine in the offline changeover area, and then distributed to the part supply station called the “buffer station” by AGVs (Photos 5 and 6).

Automatic changeover

FUJI Smart Factory provides various automatic changeover methods.

1. Automatic changeover by reading kanban IDs

2. Automatic changeover by reading panel IDs (each panel)

3. Automatic changeover based on the production schedule order (automatic changeover when the production schedule is successfully completed)

FUJI is also working to automate online changeover work after the program has been changed to the next program at the equipment.

Printer – NXTR PM

• Automatic backup pin allocation

• Automatic changeover of masks and backup blocks (Photo 7)

• Automatic solder collection and supply

Mounter – NXTR

• Automatic changeover for each module, enabling seamless changeover of different products on the same machine

• Exchangeable backup pins and nozzles

• Feeders can be set in advance using a Smart Loader

Error notification and remote-control during production

In FSF 2.0, guidance and notifications of a range of errors and warnings that occurred in the production line are issued to a smartphone and other devices the operator is carrying during production. If a single operator handles a production line, guidance is issued to ensure that the operator can effectively perform operation, eliminating unnecessary movements, waiting time, and unevenness in flow.

Autonomous control (closed-loop)

FUJI Smart Factory provides four autonomous control functions – Intelligent Process Quality Control (IPQC).

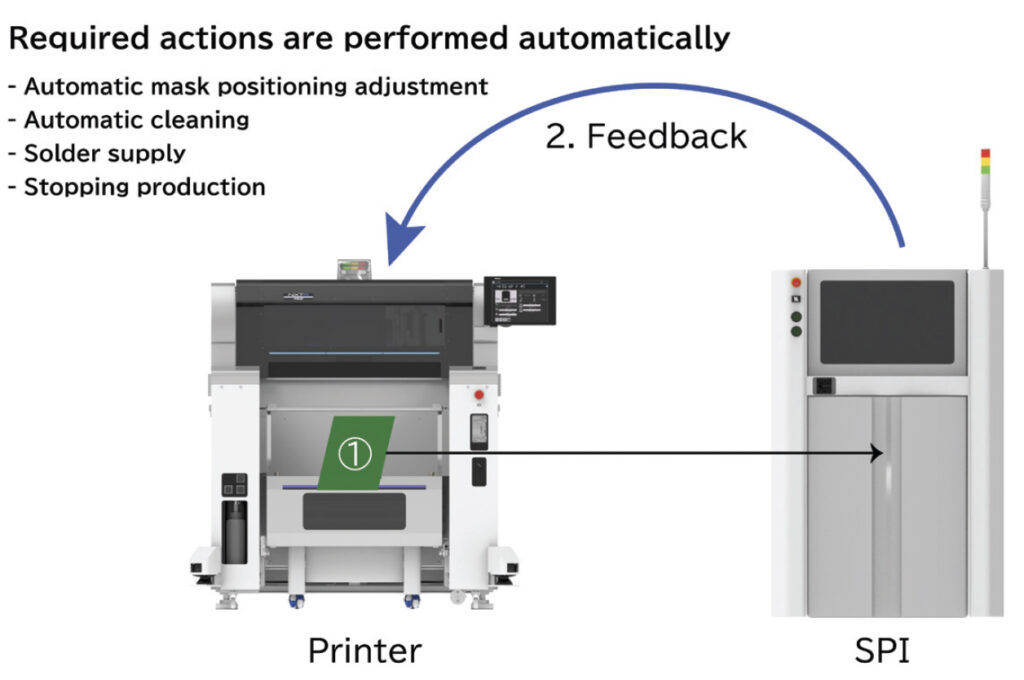

IPQC printer feedback

This is a function to send print condition correction instructions from an SPI (printer pressure, snap-off speed, cleaning frequency) in order to maintain optimal printing conditions (Photo 8).

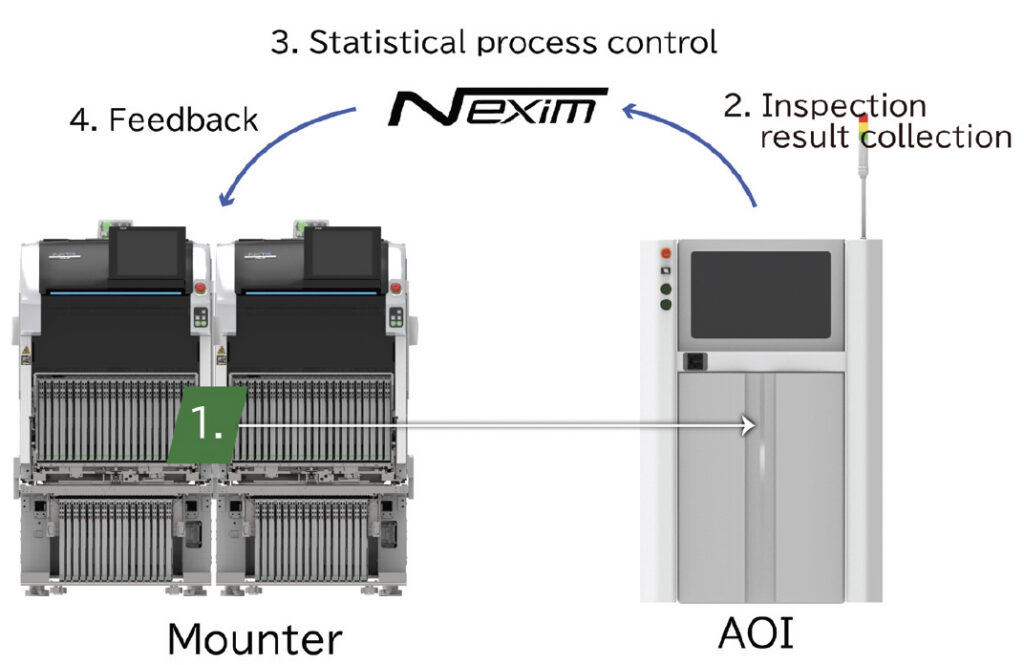

IPQC machine feedback (linking with an AOI before the reflow process)

This is a function for performing statistical analysis based on feedback from AOI inspection results and issuing instructions to the mounters or operators to maintain stable placement (Photo 9).

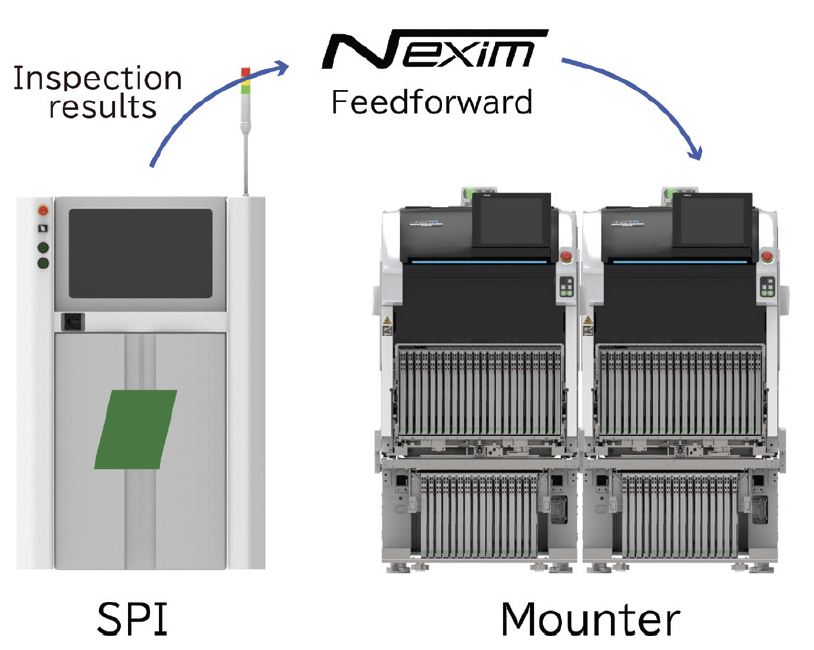

IPQC Feed Forward (SPI coordination)

This is a function for sending placement position compensation commands from an SPI to mounters (Photo 10).

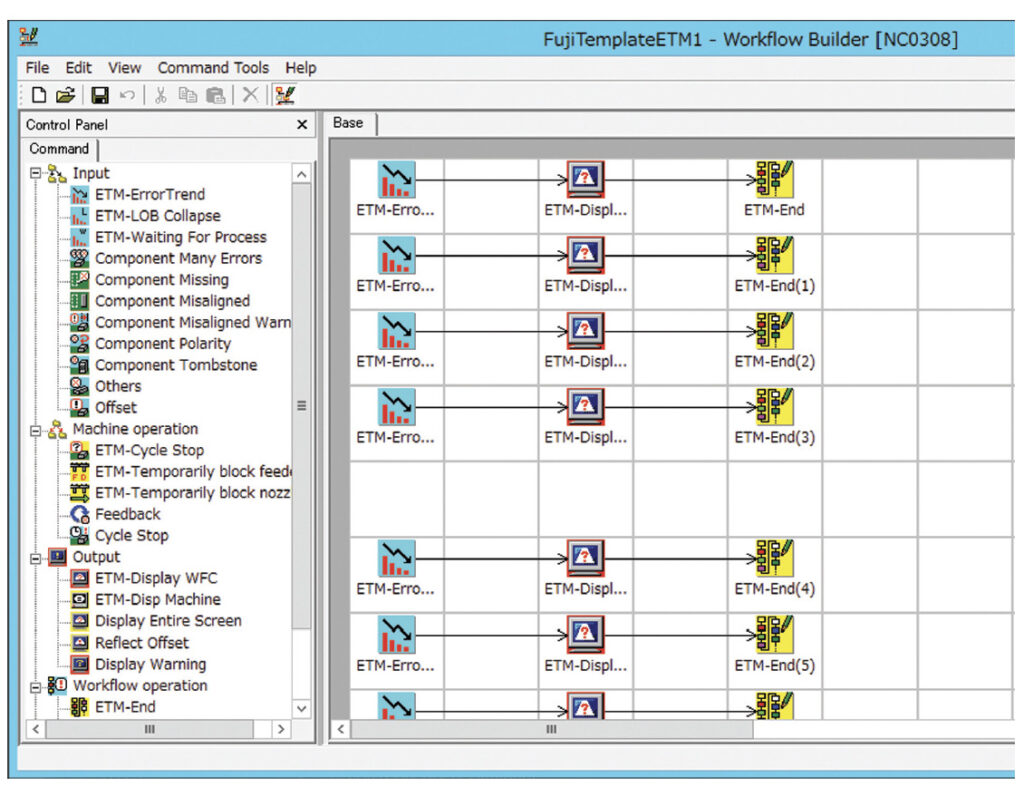

IPQC (machine error self-diagnosis and countermeasure guidance)

This function monitors and performs statistical processing for production statuses including machine errors, pickup errors, and waiting for the previous or next machine, and prompts operators or automatically instructs the equipment to take countermeasures when the necessary conditions are met.

With the workflow creation function, customers can customize how they handle errors based on their production processes (Figure 1).

Visualization of production results

Monitoring the entire line

FSF 2.0 establishes a system that can visualize production and error results to get the entire picture, from the loader at the head of the line to the unloader at the very end of the line in order to identify and analyze problems and bottlenecks in the line.

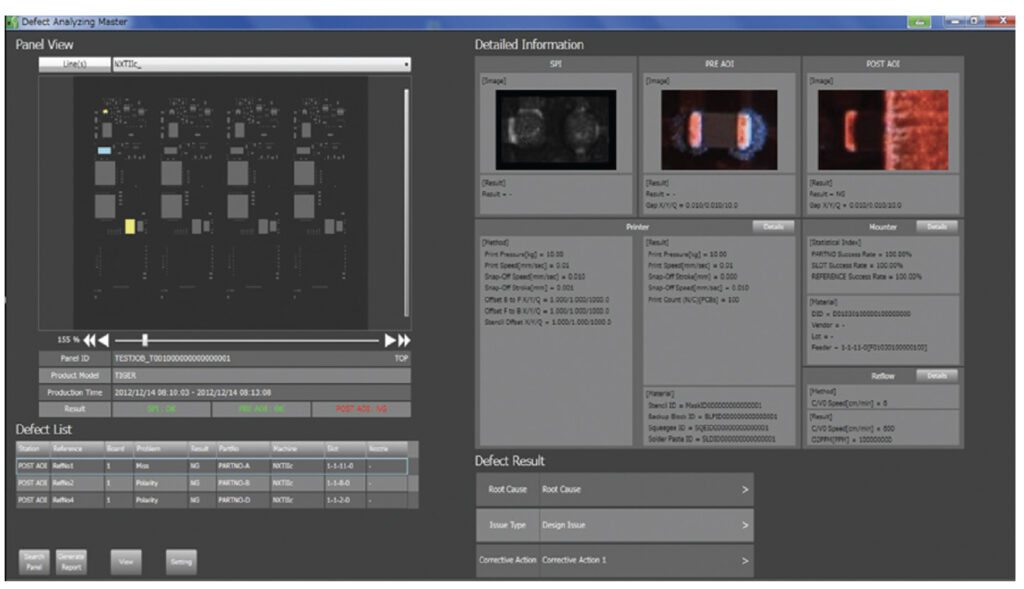

Placement defect analysis (Defect Analyzing Master)

By linking printers, an SPI, mounters, and AOIs, data regarding production of the affected panel is provided immediately when a defect is detected.

Because causes of defects can be determined quickly, defective products are prevented from continuing downstream, keeping losses to a minimum (Photo 11).

Analysis of Gaps Between the Virtual and the Real

FUJI provides a system for improving by visualizing the gap between the virtual (production plan) and the real (production results), analyzing the causes, and devising countermeasures.

Summary

FUJI has introduced the FSF 2.0 project, a next generation smart factory solution, through which FUJI will further the development to achieve automation of work at production lines and floors and production processes for the entire factory, aiming for labor saving and ultimately unmanned operations.

FUJI will continue to strive to provide smart factory solutions that excite and inspire.

About This Article:

FUJI CORPORATION provided the contents of the article.