ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SK, Ford Go on Huge Spending Spree for EV Battery Production

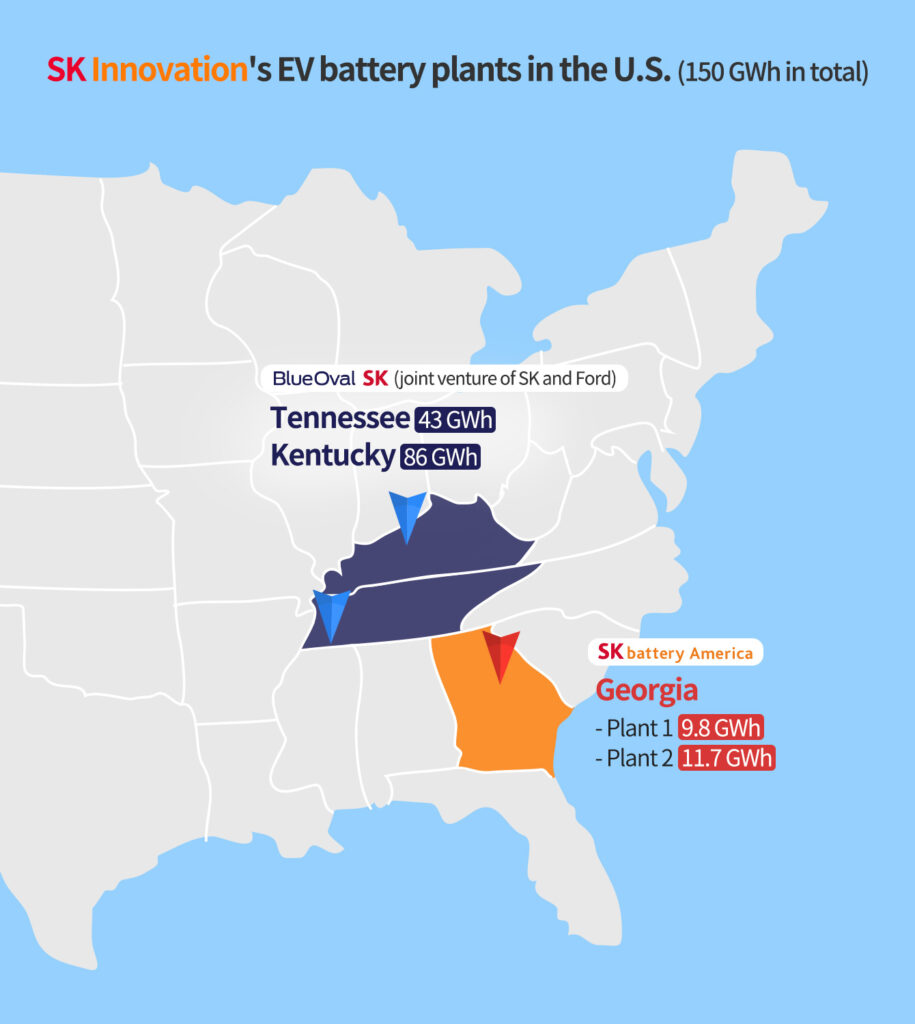

BlueOval SK, a 50:50 JV between SK Innovation and Ford Motor will go on a huge spending spree to build two EV lithium-ion secondary battery factories in the U.S.

SK Innovation and Ford agreed to invest US$4.45 billion each in the JV to finance the JV’s facility build-up project to construct two EV batteries; one in Stanton, Tennessee and the other in Glendale, Kentucky.

On top of that, Ford will alone invest US$2.5 billion to construct EV assembly lines, a R&D centers, and a recycling center somewhere in the Stanton, Tennessee EV battery factory.

The investment decision comes 4 months after the two companies signed a MOU to establish a 50:50 JV called as BlueOval SK in May 2021

The US$11.4 billion investment commitment is also to gain a foothold in the fast-growing EV and EV battery market, as the U.S. Biden administration signed an executive order to subsidize domestic production of EVs and EV batteries with various tax breaks and incentives – a policy initiative to encourage US carmakers to produce more of eco-friendly green cars like EVs and hydrogen fuel cars.

Under the policy initiative, U.S car makers like Ford are encouraged to boost production of EVs up to 40% to 50% of total car output by 2030.

Accordingly, the Tennessee EV battery factory is to be built at a land lot of 3,600 acres of Ford’s BlueOval campus in the Western Tennessee to produce 43GWh of EV batteries annually.

Spreading over a land lot of 1,500 acres, the Kentucky factory will have an annual EV battery production capacity of 86GWh.

In total, the 129GWh worth of EV battery production capacity is equal to annually producing 2.15 million units of EVs that come built with 60KW or kilowatt EV batteries. The Tennessee plant is scheduled to start production in 2025, while the Kentucky factory will come online in 2