ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Samsung Electronics Unveils Plans for 1.4nm Process Technology

At the annual Samsung Foundry Forum event, Samsung Electronics Co., Ltd. announced a strengthened business strategy for its Foundry Business with the introduction of cutting-edge technologies.

Demand for advanced semiconductors has increased dramatically amid significant market growth in high-performance computing (HPC), artificial intelligence (AI), 5/6G connectivity and automotive applications. Consequently, this trend makes innovation in semiconductor process technology critical to the business success of foundry customers. To that end, Samsung highlighted its commitment to bringing its most advanced process technology, 1.4nm, for mass production in 2027.

During the event, Samsung also outlined steps its Foundry Business is taking in order to meet customers’ needs. These include foundry process technology innovation; process technology optimization for each specific applications; stable production capabilities, and customized services for customers.

“The technology development goal down to 1.4nm and foundry platforms specialized for each application, together with stable supply through consistent investment are all part of Samsung’s strategies to secure customers’ trust and support their success,” said Dr. Si-young Choi, president and head of Foundry Business at Samsung Electronics. “Realizing every customer’s innovation with our partners has been at the core of our foundry service.”

Showcasing Samsung’s Advanced Node Roadmap Down to 1.4nm in 2027

Samsung has successfully brought its latest 3nm process technology to mass production. Consequently, it will be enhancing gate-all-around (GAA) based technology. Moreover, the company plans to introduce the 2nm process in 2025 and 1.4nm process in 2027.

While pioneering process technologies, Samsung is also accelerating the development of 2.5D/3D heterogeneous integration packaging technology. This will provide a total system solution in foundry services.

Through continuous innovation, its 3D packaging X-Cube with micro-bump interconnection will be ready for mass production in 2024, and bump-less X-Cube will be available in 2026.

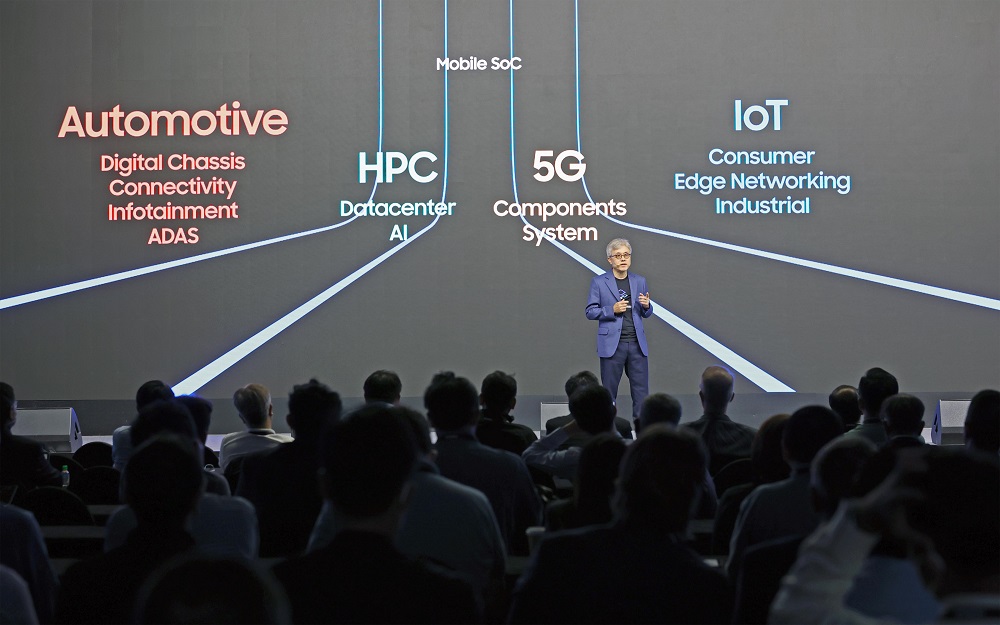

Proportion of HPC, Automotive and 5G To Be More Than 50 Percent by 2027

Samsung actively plans to target high-performance and low-power semiconductor markets such as HPC, automotive, 5G and the Internet of Things (IoT).

To better meet customers’ needs, customized and tailored process nodes were introduced during this year’s Foundry Forum. Samsung will enhance its GAA-based 3nm process support for HPC and mobile. Meanwhile, it further diversify the 4nm process specialized for HPC and automotive applications.

For automotive customers specifically, Samsung is currently providing embedded non-volatile memory (eNVM) solutions based on 28nm technology. In order to support automotive-grade reliability, the company plans to further expand process nodes by launching 14nm eNVM solutions in 2024 and adding 8nm eNVM in the future. Samsung has been mass producing 8nm RF following 14nm RF, and 5nm RF is currently in development.

‘Shell-First’ Operation Strategy To Respond to Customer Needs in a Timely Manner

Samsung plans to expand its production capacity for the advanced nodes by more than three times by 2027 compared to this year.

The company has a new fab under construction in Taylor, Texas. In addition, Samsung’s foundry manufacturing lines are currently in: Giheung, Hwaseong and Pyeongtaek in Korea; and Austin and Taylor in the United States.

At the event, Samsung detailed its ‘Shell-First’ strategy for capacity investment, building cleanrooms first irrespective of market conditions. With cleanrooms readily available, fab equipment can be installed later and set up flexibly as needed in line with future demand. Through the new investment strategy, Samsung will be able to better respond to customers’ demands.

The company also introduced investment plans in a new ‘Shell-First’ manufacturing line in Taylor, following the first line announced last year. It also revealed potential expansion of Samsung’s global semiconductor production network.

Expanding the SAFE Ecosystem To Strengthen Customized Services

Following the ‘Samsung Foundry Forum,’ Samsung held the ‘SAFE Forum’ (Samsung Advanced Foundry Ecosystem) on October 4th. New foundry technologies and strategies with ecosystem partners were introduced encompassing areas, such as Electronic Design Automation (EDA), IP, Outsourced Semiconductor Assembly and Test (OSAT), Design Solution Partner (DSP) and the Cloud.

In addition to 70 partner presentations, Samsung Design Platform team leaders introduced the possibility of applying Samsung’s processes such as Design Technology Co-Optimization for GAA and 2.5D/3DIC.

As of 2022, Samsung provides more than 4,000 IPs with 56 partners. It is also cooperating with nine and 22 partners in the design solution and EDA, respectively. It also offers cloud services with nine partners and packaging services with 10 partners.

Along with its ecosystem partners, Samsung provides integrated services that support solutions from IC design to 2.5D/3D packages.

Through its robust SAFE ecosystem, Samsung plans to identify new fabless customers by strengthening customized services with improved performance, rapid delivery and price competitiveness, while actively attracting new customers such as hyperscalers and start-ups.

Starting in the United States (San Jose) on October 3rd, the ‘Samsung Foundry Forum’ will be sequentially held in Europe (Munich, Germany) on the 7th, Japan (Tokyo) on the 18th and Korea (Seoul) on the 20th. Customized solutions for each region will be introduced. A recording of the event will be available online from the 21st for those who were unable to attend in person.