ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Epson Boosts VT6L 6-Axis Robot Series

As the rise of automation continues across various industries, businesses are seeking innovative, easy-to-integrate robotic solutions to improve operational efficiency, cost savings and throughput. Dedicated to making robot integration simple for all users, Epson Robots expands its VT6L Series lineup with the VT6L-DC All-in-One 6-Axis Robot. Also, the company increased the functionality of its no-code, easy-to-use Epson RC+® Express programming software.

Epson VT6L-DC All-in-One 6-axis Robot

The VT6L-DC all-in-one 6-axis robot is a DC-powered version of VT6L. It delivers next-level technology and is ideal for mobile solutions. Now, an industrial-grade, 6-axis robot can be mounted to an autonomous mobile robot (AMR) for warehousing applications or on a mobile platform to easily transport between workstations.

VT6L-DC offers the same powerful features found in Epson’s high-end robots, at an exceptional value. It features a built-in controller, reach of up to 900mm and a payload of up to 6kg. These features enable it to have high throughput and operational flexibility in a space-saving design. It also comes equipped with two powerful development environments – Epson RC+ for full-featured, easy-to-learn programming and Epson RC+ Express for no-code programming.

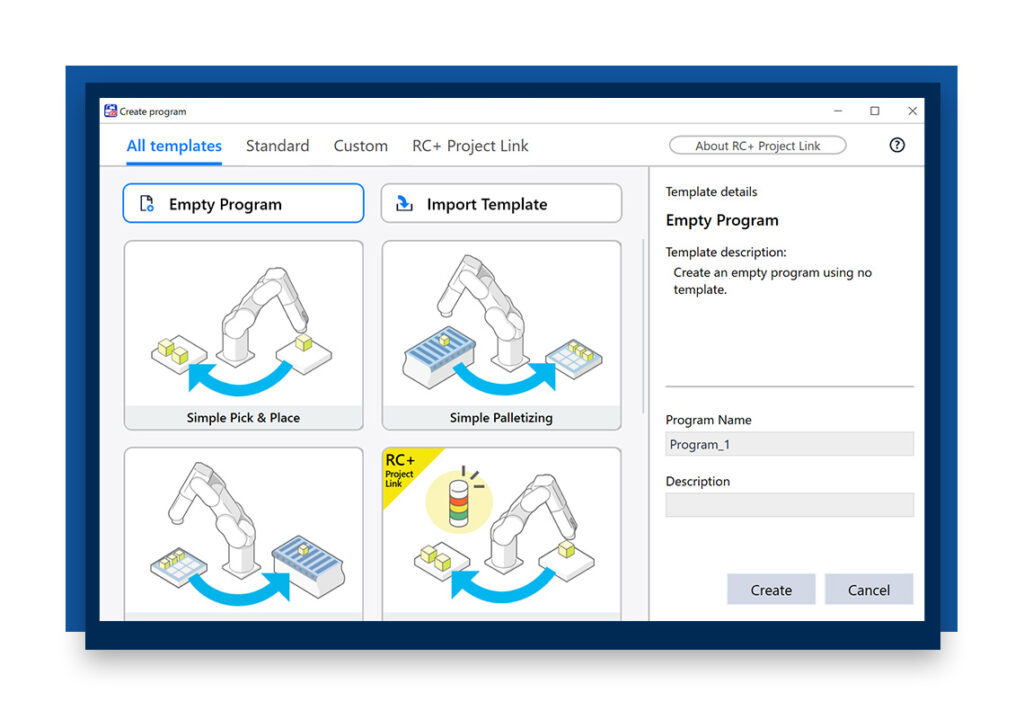

Epson RC+ Express

Ideal for automation novices with little to no programming experience, Epson RC+ Express offers a simple visual-based teaching environment. It features an easy-to-follow, block-style format, and ready-to-use templates. Additionally, it has time-saving features to get Epson SCARA and 6-axis robots up and running fast. It was also previously available on select Epson robots. Now, the intuitive software works with hundreds of Epson SCARA and 6-axis robots. These range from the All-in-One Series to the highest-performance GX- and C-Series. The software is equipped with time-saving features, such as Epson proprietary Focus Assist technology with autogenerated fields for quick and easy setup, and a built-in 3D simulator to help visualize and fine-tune applications.

“As more businesses implement automation to address workforce challenges, Epson recognizes that more users require not only easy-of-use applications, but also the flexibility to be mobile,” said Scott Marsic, group product manager, Epson Robots.

“Epson is committed to providing a simplified automation experience. Solutions like the VT6L-DC empower warehousing, logistics and machine tending operators to move a traditional 6-axis robot from place to place rather than mounting it in a single, stationary location. With simple, visual-based programming software like RC+ Express, users can get their robotic automation solutions up and running quickly,” continued Marsic.

Additional VTL6-DC, RC+ Express Features

Specifically, the new VTL6-DC features a “SlimLine design” highlighted by its compact wrist pitch. It enables access to hard-to-reach areas in confined spaces. It can be installed in minutes and requires less time and money for system integration. Also, the new robot can be optionally integrated with vision guidance, which is designed specifically for robots. This feature makes it easy to automate simple applications when vision is required. With its simplified cabling, the hollow end-of-arm design makes end-of-arm tooling easier than ever. The encoder does not require a battery, minimizing downtime and reducing overall cost of ownership. VTL6-DC is ideal for machine-tool and injection-molding load/unload, pick-and-place, dispensing and mobile applications.

Meanwhile, RC+ Express is simple to navigate. Its clear, intuitive, visual user interface makes it easy to learn and manage key functions like jogging, gripper control and motion. The software includes common application templates to quickly create common pick-and-place, palletizing and depalletizing applications.

A built-in 3D simulator lets users conveniently program and fine-tune applications before hardware setup. The software can also run the robot at low power and speed in rehearsal mode when testing new programs. It operates in tablet-based Windows® OS environment, making it compatible with touchscreen devices and PCs to easily create robot applications. Lastly, it features low total cost of ownership as Epson RC+ Express is included with robot purchases and no recurring licensing fees.