ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

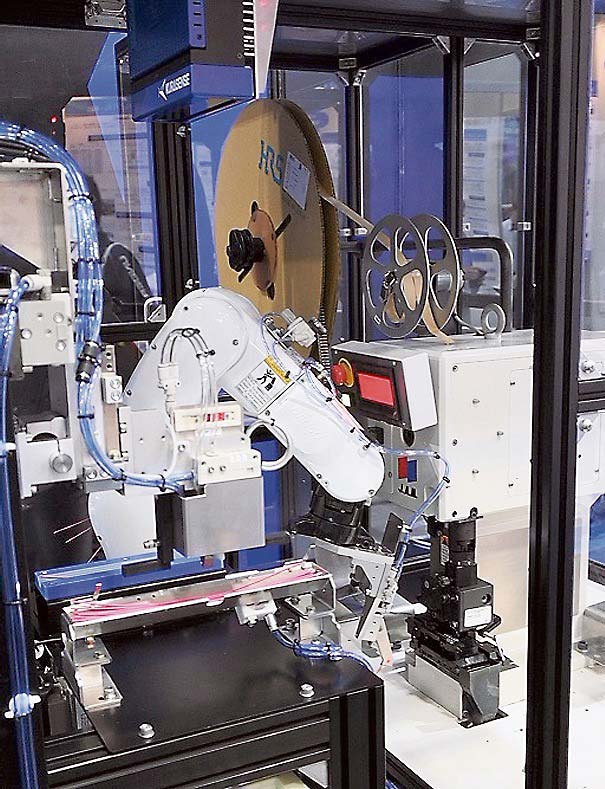

KURABO Showcases Robot Package for Wire Harness Production at RoboDEX

KURABO INDUSTRIES LTD. demonstrated a robot package for wire harness production at RoboDEX Nagoya. The robot package is equipped with KURASENSE high-speed three-dimensional (3D) vision sensor.

RoboDEX Nagoya is one of the three shows that composed the FACTORY INNOVATION Week Nagoya held at Portmesse Nagoya in Nagoya, Aichi Prefecture in Japan in October.

KURABO 3D Vision Sensor

Prior to accepting orders for the robot package in November, KURABO INDUSTRIES demonstrated an automated production of wire harnesses using the robot package, thus unveiling the latest KURASENSE. During the demonstration, the take-out unit took out cables one by one from the bundle. Then, the robot held the cable and set it to the terminal crimping machine. Lastly, it evaluated the quality and inserted the terminal to the connector.

3D vision sensors serve as the robot’s eye and brain. Conventional 3D vision sensors could recognize only hard objects with solid shapes. In contrast, KURASENSE recognizes wire-type objects like flexible cables, of which, the shape and the direction of the tip tend to change, down to 0.5mm at high speed. Thus, it enables the robot to perform fine handling.

The new robot package enables the automation of works that previously depended on manpower, while ensuring equivalent speed and quality assurance.

The basic robot package comprises the 1) KURASENSE-C100; 2) Kurabotte robot hand for cables; 3) one cable take-out unit; 4) a set of robot frame, safety fence, etc.; and 5) industrial vertical articulated robot. It can be combined with a variety of robots. Processing machine, testing machine, visual inspection camera unit, and connector assembly unit are available on optional basis.

The COVID-19 pandemic has disrupted the industry supply chain. Moreover, the depreciation of yen prompted the return of manufacturing back to Japan. Against the backdrop, needs for robots have been increasing to simultaneously achieve automation, which is indispensable to improve production efficiency, according to KURABO.