ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SCREEN Launches New OLED Panel Production Systems

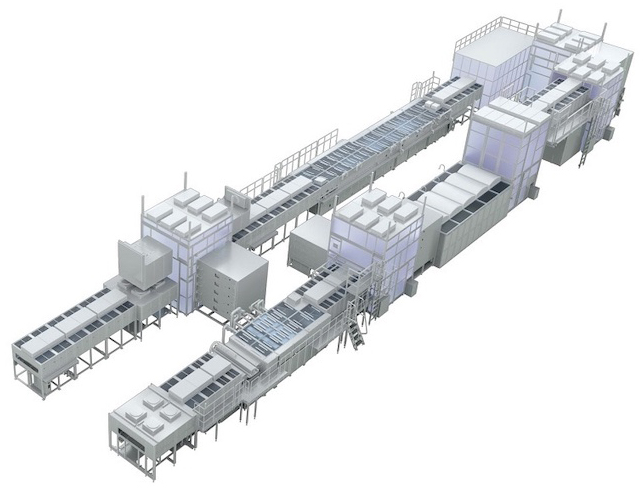

SCREEN Finetech Solutions Co., Ltd. (SCREEN FT) has finalized development of its new SK-E2200G and SK-E2200H systems. Particularly, the systems are suitable for processing of the 8th generation1 substrates used in the latest OLED panels.

These displays are currently in high demand, particularly for applications such as IT devices and automotive systems. More importantly, SCREEN FT have launched these models to suit the growing demands from the said fields.

Suit Emerging Trends

Demand for displays for IT products such as smart devices has grown rapidly in recent years. Particularly, the widespread shift to remote working and online classes has enabled this growing trend. Similarly, the current transition to electric vehicles and advances in self-driving technologies will also lead to steady growth in both the size and installation of automotive displays.

With increasingly high-definition, high-value-added displays, primarily OLED panels, adopted for these applications, there has been a growing need for OLED production systems for 8th generation substrates. In addition, these advanced systems can produce larger number of panels from a single glass substrate.

In response to these industry trends, SCREEN FT has developed two new coater/developer systems, specifically for handling 8th generation substrates. Particularly, they are the SK-E2200G, designed for use in the formation of OLED backplanes, and SK-E2200H, configured for the processing of touch sensor panels. Both models will join SCREEN FT’s existing E series group of production systems for OLED panels.

Improve Productivity, Shorter Takt Time

The E series lineup resolves various issues that occur during the manufacturing process for OLED panels, including the generation of organic contaminants, minute particles and static electricity. These capabilities markedly improve yield rates, enabling E series models to deliver industry-leading productivity. They have already established an impressive track record as mass production systems for 6th generation2 substrates.

The soon to be launched SK-E2200G and SK-E2200H inherit the same basic specifications present in the 6th generation substrates while also offering shorter takt times. Compared to SCREEN FT’s conventional systems, they improve productivity by around 10 percent3. Moreover, they ensure a stable supply of OLED panels even as demand continues to grow.

Furthermore, their overall length is around 30 percent3 shorter than conventional systems, providing significant space savings. The SK-E2200G has also been designed with a “1 by 2” configuration4. This enables it to connect to two exposure systems. This feature allows factory space utilization far more efficiently than before.

SCREEN FT is already planning further additions to its E series lineup in the future. It believes these systems will make a major contribution to the reliable production of OLED panels and other high-definition, high-value-added displays.

Notes:

1Eighth generation substrate sizes: 2,200 x 2,500, 2,250 x 2,600 and 2,290 x 2,620 mm.

2Sixth generation substrate size: 1,500 x 1,850 mm.

3Comparison with SCREEN FT’s 8th generation model, the SK-2200G

4A production line that previously included two coater/developers and two exposure systems allow configuration with only a single coater/developer, providing a major space saving. Multi model on glass (MMG) processing is also supported, enabling the production of panels of different sizes from the same substrate. In addition, exposure processing is possible for a time longer than the line takt by operating two exposure systems in parallel.

Levicoater is a registered trademark and/or trademark of SCREEN Holdings Co., Ltd.