ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NSK New Feed Drive Automates Machine Tools

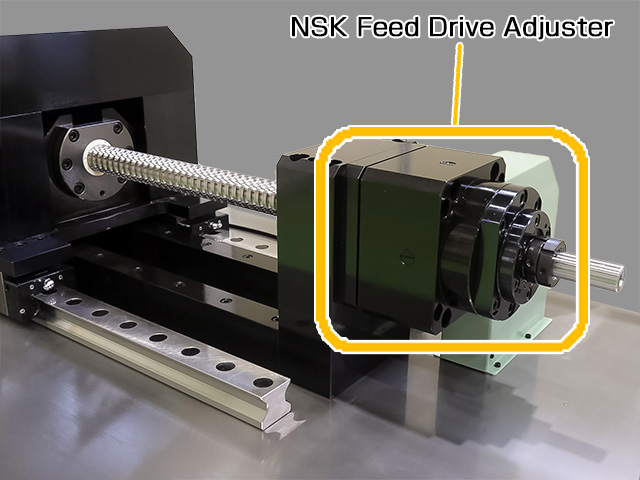

NSK Ltd. has developed the NSK Feed Drive Adjuster, a ball screw feed drive accessory. Accordingly, it enables ease of handling and automation of feed drives in machine tools and other production equipment.

Recently, the company exhibited the NSK Feed Drive Adjuster at the 31st Japan International Machine Tool Fair (JIMTOF 2022). Consequently, NSK said it will continue to develop and propose new solutions toward supporting the future of machine tools.

Background

Manufacturing fields uses a variety of production equipment. Hence, efforts are underway to realize a sustainable society that is carbon neutral and with zero emissions.

Most importantly, the society will also become highly automated and autonomous through big data, backed by the emergence of digital technology.

To improve machining accuracy and productivity, skilled technicians employ design measures and on-site adjustments on machine tools such as machining centers. Particularly, to reduce the effects of machine deformation.

In recent years, machine tool builders are improving ease of operation and reducing the necessity for specialized technical and skilled labor. This is possible through rapidly evolving digital technology and data.

Features

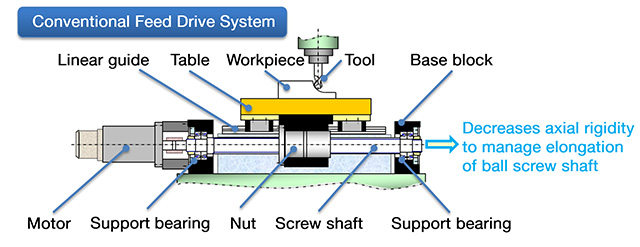

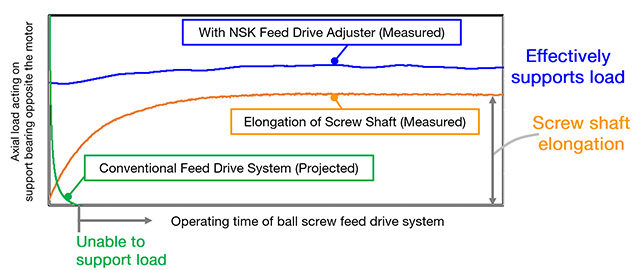

Elongation of the ball screw shaft due to temperature rise in machine tool feed drive system affects machine performance. For that reason, the NSK Feed Drive Adjuster minimizes the said variation and deterioration.

Normally, one way to address elongation of a screw shaft is releasing axial displacement on one side of the mechanism. This supports the screw shaft to prevent abnormalities or failure in the feed drive system.

However, this reduces ability to bear axial loads and prevents the machine tool from maintaining effective support rigidity (stiffness). Thus, affecting the accuracy and quality of machining.

To address this issue, NSK developed the NSK Feed Drive Adjuster to maintain rigidity (stiffness) and dynamic characteristics in the support bearings on one side, while tracking axial displacement. This minimizes changes in rigidity (stiffness) even operational or environmental factors affect the feed drive system. These factors include heat generation. Thereby, reducing variation (deterioration) in machining accuracy, quality, and productivity.

Benefits

Applying the NSK Feed Drive Adjuster technology to ball screw feed drive systems has several benefits. First, it continuously maintain the rigidity (stiffness) of the ball screw feed drive system. Thus, improving machining accuracy, quality, and productivity.

Second, it enables designing high performance ball screw feed drive system supports without specialized knowledge. It also eliminates need for specialized technical skills in fine-tuning control equipment and changing feed rates to match changes in machining conditions.

In addition, the adjuster reduces lost time and environmental impact by reducing or eliminating the need for machine warm-up routines and additional cooling procedures.

It also realizes optimized coordination of ball screw feed drive system and numerical control system. Furthermore, it improves controllability when combined with NSK ball screws.

Lastly, the NSK Feed Drive Adjuster is possible to use even without electricity (or any energy supply). Thus, contributing to standardization of designs for advanced automation and reduction of environmental impact.