ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Rokko Propels Novel Materials for IC Industry

Rokko Holdings Ltd has marked its 30th anniversary as a proven specialist in the global semiconductor industry. This after the company has overcome successive challenges and business cycles through its commitment to innovation and R&D, with a focus on quality and strong technical support at the core of its corporate culture.

The company has over 89 patents granted related to its semiconductor equipment and advanced material divisions. Moreover, Rokko has remained nimble while forging industry leadership in providing advanced materials support as well as high-precision equipment for the back end (assembly, testing and packaging services) of the industry.

Prospects Remain Bright

Headquartered in Singapore, Rokko has benefited from the country’s predictable industrial policy and robust legal framework that protects Intellectual Property. Fortuitously, the Singapore domicile has also allowed Rokko to navigate recent challenges of the U.S.-China ‘tech war’ that have impacted the semiconductor industry.

Rokko has a substantial customer base in China and Taiwan which accounts for over half of its annual revenue for the past few years. The balance is derived from the ASEAN region which has avoided geopolitical tensions affecting the chip sector.

Rokko’s Founder and Managing Director Mr Gary Lim said, “As 2022 draws to an end, we mark a major milestone in our history as a Singapore enterprise. Our management team has remained resolute in innovating constantly to stay ahead of the curve. This spirit has helped us to overcome many downturns in industry cycles, and in riding out the recent challenges of the pandemic.”

According to market research by Gartner, the global semiconductor industry is estimated to achieve global revenue of USD612 billion in 2022. With many industry experts expecting the revenue to rise to USD1.0 trillion by 2030, the sector – and Rokko’s prospects – remain bright.

Lim established Rokko in 1992 with an initial 12 employees. It has grown to a team of 250 that includes a pool of talented engineers, operating from 2 facilities in Singapore (including the corporate headquarters) and another two manufacturing facilities in Johor state, Malaysia.

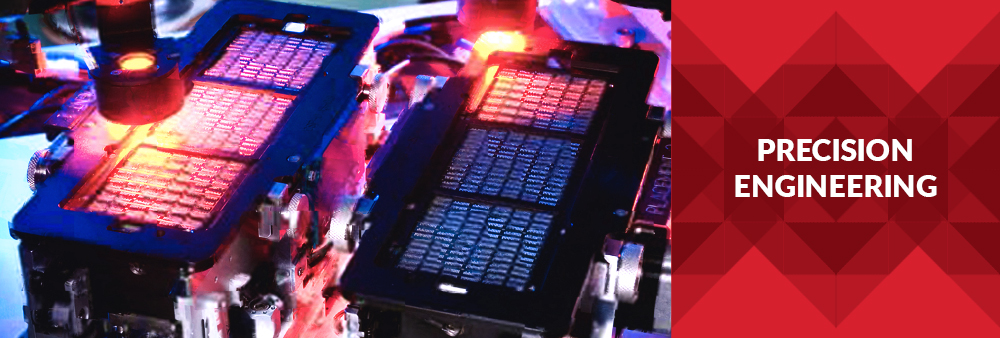

Edge in Volume Production

The company is known for its proprietary back-end semiconductor high-precision equipment such as dual-track Auto Sawing and Sorting systems and Auto Vision Inspection (AVI) systems. Particularly, they are sought after for their high productivity, reliability, and quality.

These and other breakthrough equipment and tooling designs developed by Rokko’s exceptional R&D team have set new industry standards.

Meanwhile, customers using Rokko’s products and solutions have been able to halve their capital expenditure for the complex singulation process of back-end semiconductor packaging and assembly in recent years.

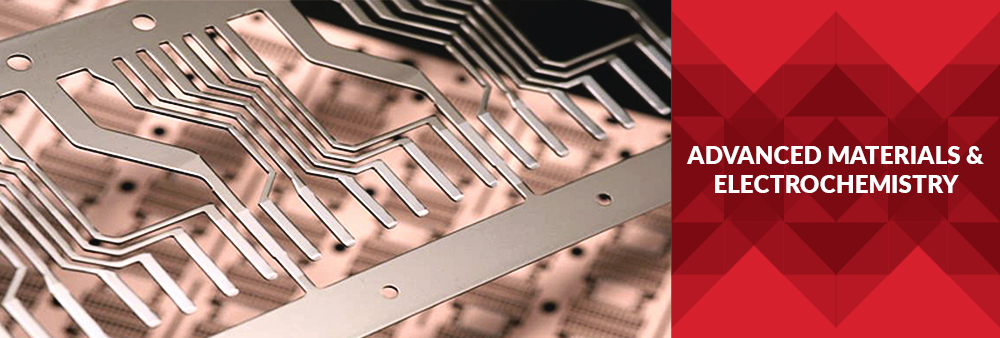

In its second area of semiconductor expertise – advanced materials for semiconductor packaging – Rokko has successfully developed a complex IC leadframe design with an extremely fine line etching process to meet customers’ advanced packaging standards.

Rokko’s major customers now include the world’s top-ranking Outsourced Semiconductor Assembly and Testing (OSAT) players as well as MNCs involved in advanced packaging materials. This successful record has helped Rokko to achieve a critical competitive advantage in volume production after substantial investments in R&D and capacity expansion in recent years.

With a strong commitment to sustainability, the company’s environmentally conscious investments include a certified ‘Class A’ wastewater management system at its facility in Malaysia.

Rokko’s products are also certified for the automobile industry’s quality standard – IATF16949 – and are also accredited with the ISO14000 environmental compliance standard.