ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

UPT Beefs Up IC Test Sockets, Other Solutions

Japanese provider of fine precision metal fabrications United Precision Technologies Co., Ltd. (UPT) has been stepping solutions to advance semiconductor manufacturing technology. For that reason, the company wants to help customers overcome their challenges offering engineering solutions that make use of its miniaturization and precision technologies.

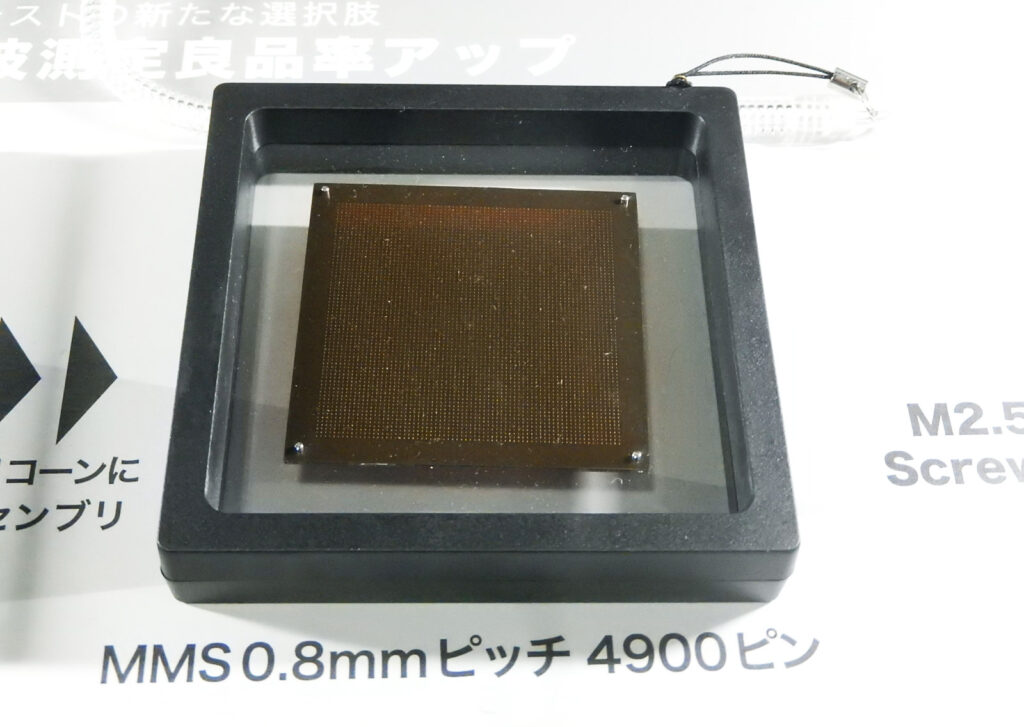

Micro metal socket (MMS), UPT’s semiconductor test socket, supports high frequency and high current. Particularly, it uses the company’s originally developed material and features a new structure as a next-generation test socket. In addition, it supports 60GHz, and high frequency and high current with a rated current of 1A per one contact.

Furthermore, it features low force with 0.10N per one contact, high reliability structure, and narrow pitch arrangement with the smallest contact pitch of 0.15mm, which is among the smallest in its class.

Ensures Longer Equipment Life

UPT provides MMS solutions that meet requirements and solve challenges in the semiconductor test process. These challenges include the support of high frequency and high current to meet the shift to 5G and beyond 5G. Also, other challenges include reduction of load on test handler to enhance its service life, and the miniaturization of semiconductors with narrower pitches.

MMS adopts Union Alloy, UPT’s originally developed material with excellent electric characteristics. Ultrashort transmission path with the smallest contact pin height of 0.45mm supports high-speed transmission at 60GHz with a rated current of 1A. MMS also excels in heat dissipation performance and has an operation temperature range of -40 to +150℃. Furthermore, it also supports communication modules and camera modules, as well as optical modules and millimeter wave communication modules.

In general, the load on test handler, which receives contact pressure of the contact is 0.49N per one contact and amounts to several tens of tons in total. However, the low force contact of MMS can reduce the load on test hander by about 80 percent from conventional test sockets.

Thus, MMS ensures longer life of equipment. Furthermore, it also improves the degree of freedom of mechanical design and realizes downsizing of equipment and reduction of components costs.

Meets Narrow Pitch Requirements

MMS supports contact pitch from 0.15mm, one of the smallest pitches in the industry. It features a housingless structure and allows the manufacture of sheets in accordance with application. Specifically, it supports packages for smartphones and next-generation semiconductors, which require narrower pitches.

UPT premiered a 0.8mm-pitch, 4,900-pin socket (with a pin length of 3.3mm) of MMS at SEMICON JAPAN 2022 held in December at Tokyo Big Sight. It drew a lot of attention of visitors.

Meanwhile, Union Cooling Tech is a compact, high-performance cold plate. It has a high-precision channel with the minimum width of 70μm and features a precision multilayer structure. It achieves one-stop thermal solution.

At SEMICON JAPAN, UPT also premiered MPC-BLOCK connector, which supports multipoint contact, and high-current and high-speed transmission. Equipped with a high-speed multipoint contact block, MPC-BLOCK supports high current and high-speed transmission and features high contact reliability. It suits electrical inspection of semiconductors, electronic components, various modules, and displays.