ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

NTN Pitches Unique Wrist Joint Module at RoboDEX

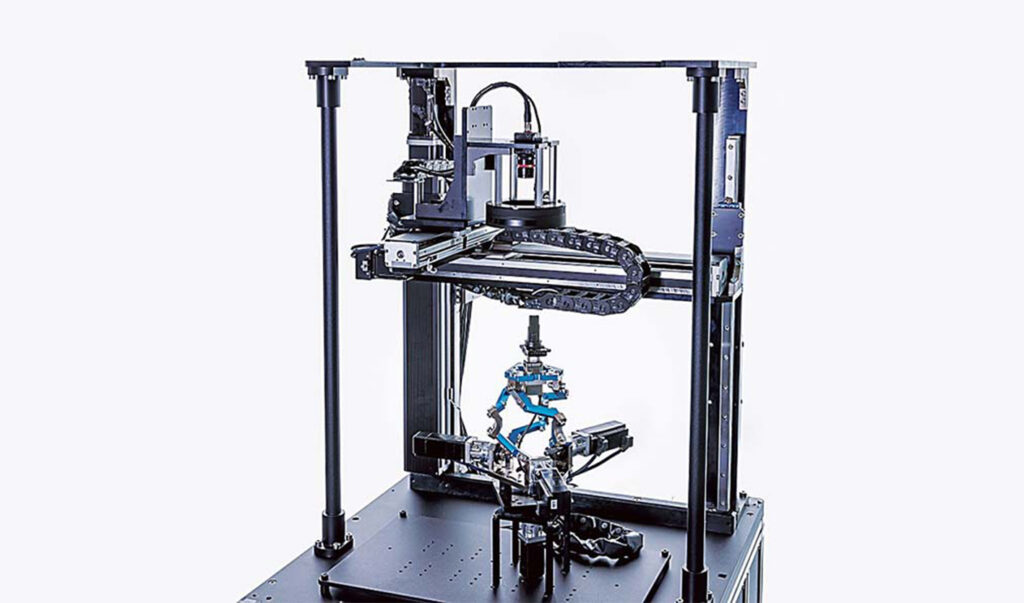

NTN Corporation showcased the i-WRIST Wrist Joint Module for robots at the 7th RoboDEX held in January in Tokyo, Japan. The company demonstrated i-WRIST mounted in upward and sideways directions. This is the first model with this capability other than the conventional upward direction.

The i-WRIST Wrist Joint Module is a compact machine, thus saving on installation space. It features a wide operating range as a positioning device. Moreover, it performs minute changes of position (angle) at high speeds with the same smooth movements as a human’s wrist. On the contrary, general vertical articulated robots are not good at such movements.

Can Be Mounted Upward, Sideways

NTN promoted i-WRIST, which can be mounted in upward and sideways directions on top of the conventional downward direction. The company also pitched its capability to automate various work processes when combined with a camera, lighting, rotation actuator, and linear motion actuator. Those processes include appearance inspections, grease dispensing, cleaning, and assembly.

NTN proposed a wide variety of applications by showcasing i-WRIST mounted in the upward direction. For example, using i-WRIST to control workpieces and the actuator to control the camera and the lighting enables the use of large lighting.

Specifically, the equipment on display measured W800×D850mm. It featured a camera working distance (WD) of 250mm, a high-speed inspection of multiple surfaces at 0.2 seconds per point at the maximum, and a maximum work size of φ140×H100mm. NTN recommends installation of the equipment in inspection processes of resin molded components, electronic control units, and small components.

Also, NTN demonstrated the i-WRIST mounted in the sideways direction. It showed the possibility to inspect workpieces looking up from below. Moreover, inspection is available on all the surfaces of workpieces, except for the gripped surface.

This equipment measures W1100×D1130mm. It features a camera WD of 115mm, high-speed inspection of multiple surfaces at 0.2 seconds per point, and a maximum work size of φ250×H250mm. The company offers a system for inspection of large aluminum casting products, inverter cases, and all-side-painted parts.

Moreover, the bend angle of i-WRIST changes between 0 to 90°and the swing angle 360° by converting coordinates using the dedicated controller. It allows optimum equipment configuration in accordance with application and installation space.

With this equipment, NTN aims to capture replacement demand from visual inspections by workers, appearance inspections using multiple cameras, and appearance inspections by other robots.