ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Automotive Industry Installs 1M Robots in 2021

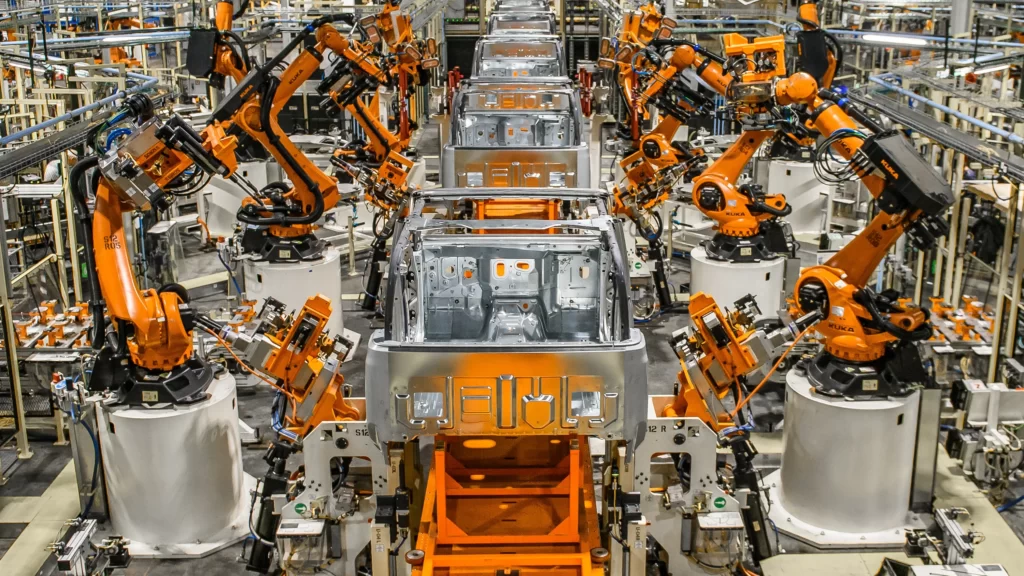

The automotive industry accounts for the largest number of robots working in factories around the world. The industry’s operational stock hit a new record of about 1 million units. This represents about one-third of the total number installed across all industries.

“The automotive industry effectively invented automated manufacturing,” says Marina Bill, President of the International Federation of Robotics. “Today, robots are playing a vital role in enabling this industry’s transition from combustion engines to electric power. Robotic automation helps car manufacturers manage the wholesale changes to long-established manufacturing methods and technologies.”

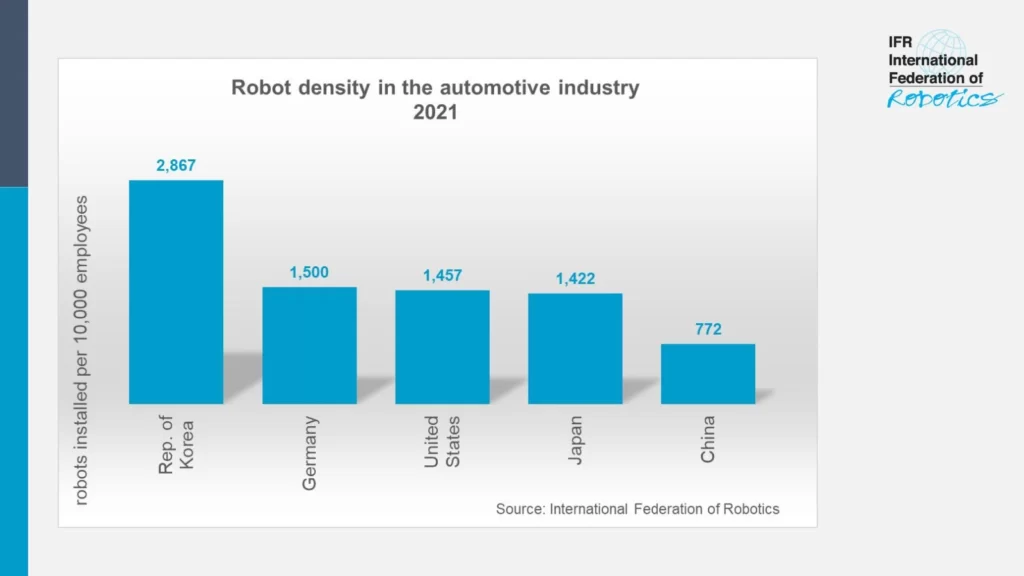

Robot Density in Automotive

Robot density is a key indicator that illustrates the current level of automation in the top car-producing economies. In the Republic of Korea, 2,867 industrial robots per 10,000 employees were in operation in 2021. Meanwhile, Germany ranks in second place with 1,500 units, followed by the United States counting 1,457 units, and Japan with 1,422 units per 10,000 workers.

Moreover, the world´s biggest car manufacturer, China, has a robot density of 772 units, but is catching up fast. Within a year, new robot installations in the Chinese automotive industry almost doubled to 61,598 units in 2021. This accounts for 52% of the total 119,405 units installed in factories around the world.

Electric Vehicles Drive Automation

Mainly, ambitious political targets for electric vehicles are forcing the car industry to invest. For one, the European Union has announced plans to end the sale of air-polluting vehicles by 2035. Meanwhile, the US government aims to reach a voluntary goal of 50% market share for electric vehicle sales by 2030. Moreover, all new vehicles sold in China must be powered by “new energy” by 2035 – half of them must be electric, fuel cell, or plug-in hybrid – the remaining 50% are hybrid vehicles.

Most automotive manufacturers who have already invested in traditional “caged” industrial robots for basic assembling are now also investing in collaborative applications for final assembly and finishing tasks. Tier-two automotive parts suppliers, many of which are SMEs, are slower to automate fully. Yet, this is bound to change as robots become smaller, more adaptable, easier to program, and less capital-intensive.